Capsule shaping automatic pressure holding system

A capsule and automatic technology, applied in the field of automatic pressure-holding system for capsule shaping, can solve problems such as over-stretching, reducing the number of capsules used, and accelerating rubber aging, so as to prevent uneven stretching or over-stretching, and eliminate pressure fluctuations in the capsule. The effect of increasing the number of uses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

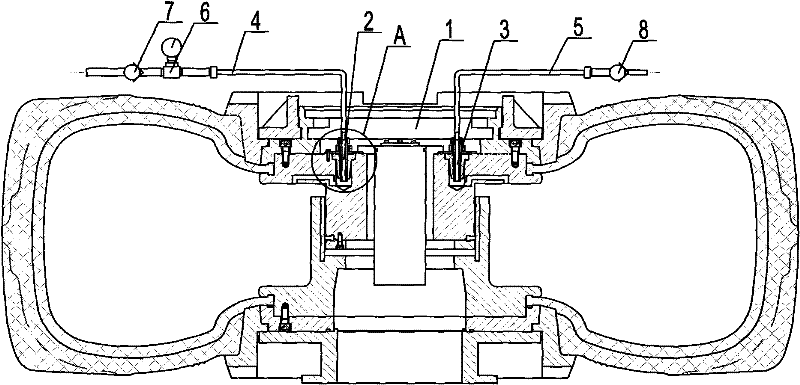

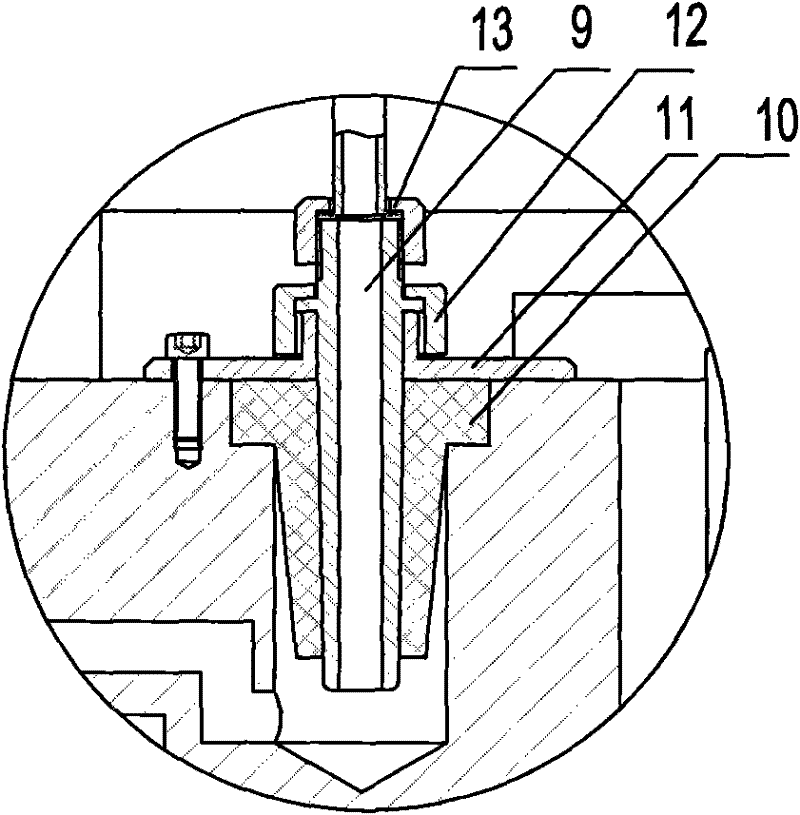

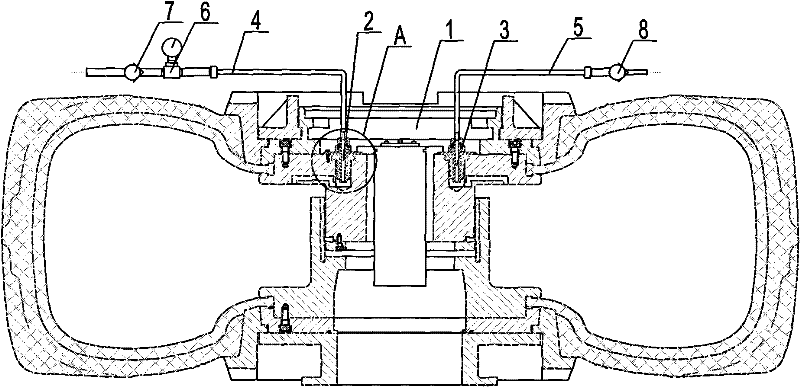

[0011] Such as figure 1 , 2 As shown, an automatic pressure maintaining system for capsule setting includes a capsule fixture 1, a water inlet and a water outlet are arranged on the capsule fixture 1, the water inlet is communicated with the water inlet pipe 4 through a hollow plug 2, and the water inlet pipe 4 is provided with Pressure gauge 6 and one-way overflow valve 7, the other end of the water inlet pipe is connected to the pipeline system for automatic pressurization; the water outlet is connected with the outlet pipe 5 through the hollow plug 3, and the outlet pipe 5 is provided with a one-way overflow valve. The flow valve 8 is used for automatic pressure relief protection when the pressure is too high. The hollow plug includes a hollow connecting rod 9, the lower part of the hollow connecting rod 9 is wrapped with a tapered sealing ring 10, the hollow connecting rod 9 is fixed on the capsule holder 1 through the pressure plate 11 and the fixing nut 12, and the uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com