Vertical recombined hot-pressed plywood and its production method

A production method and plywood technology, applied in chemical instruments and methods, layered products, bonding of wooden veneers, etc., can solve the problems of low product recycling rate, low performance, large waste, etc., and achieve environmental protection resource recycling The effect of utilization, not easy to delaminate and degumming, not easy to deform

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with specific embodiments.

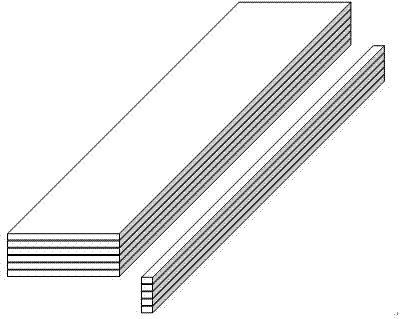

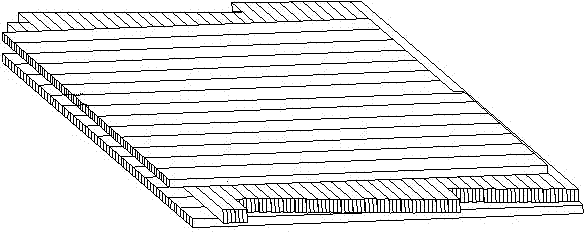

[0027] A vertical recombined heat-pressed plywood of the present invention includes a surface layer, a core layer and a bottom layer, and the core layer includes several layers of single layers that are superimposed and pasted together (the number of single layers is generally three or more odd numbers), The single layer is composed of side-by-side long strips pasted together. The long strips are formed by cutting waste plywood along the longitudinal direction. All of the same thickness, the strips in adjacent monolayers are perpendicular to each other.

[0028] The long strips are made by cutting the scraps of old veneer plywood. The newly formed plywood changes the original way of laying along the veneer layer, and lays it in a vertical way with the new veneer layer. The plywood is not easy to deform, delaminate and degumming. The quality of the board is good, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com