Form rolling method for involute gear

An involute gear and rolling technology, applied in the field of forming and rolling, can solve the problems of complicated gear manufacturing operations, increased man-hours and manufacturing costs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

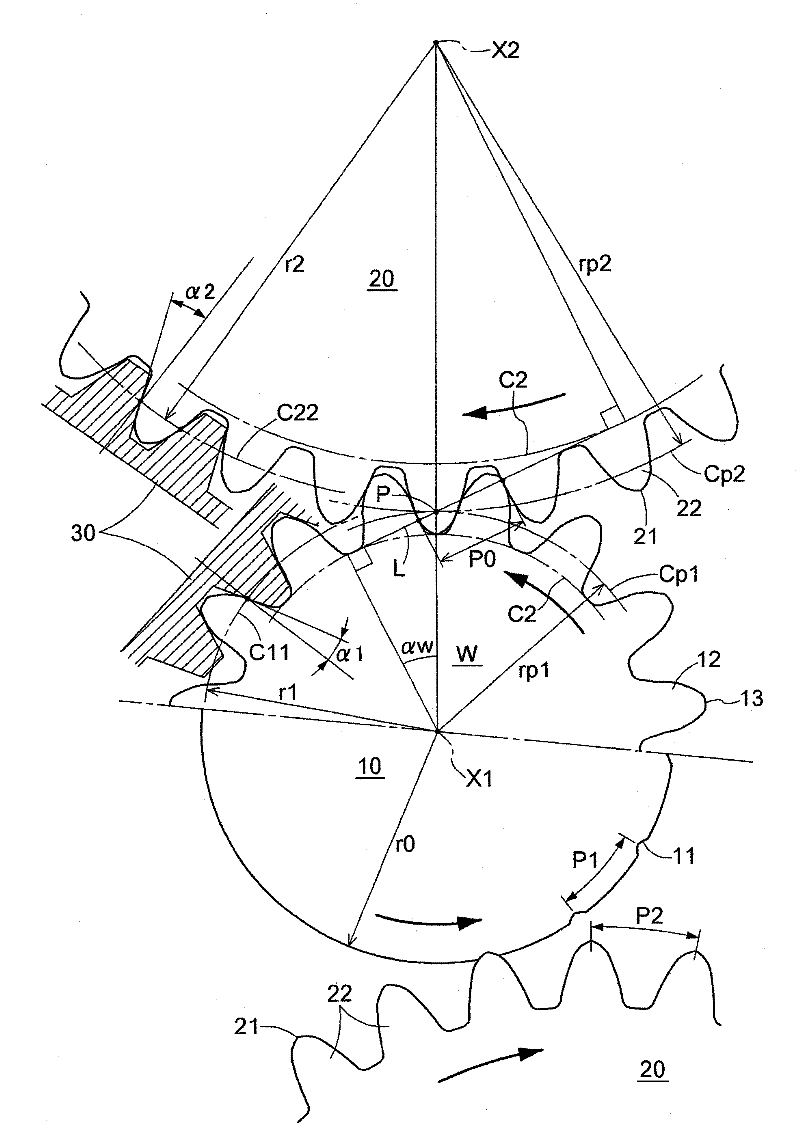

[0028] Hereinafter, an embodiment of a form rolling method for an involute gear will be explained with reference to illustrations of the accompanying drawings.

[0029] The form rolling method for an involute gear according to an embodiment relates to a method for forming a gear by form rolling an involute gear while using a workpiece including a cylindrical configuration ( That is, hereinafter referred to as the gear) when optimizing the contact of the circular die (i.e., hereinafter referred to as the die) with respect to the workpiece, and then further by properly pressing the die into the workpiece, with high precision and mechanical characteristics above is excellent.

[0030] Such as figure 1 As shown, form rolling of the workpiece 10 is performed using a die 20 . figure 1 The lower half of the figure shows the state that the die 20 starts to press the workpiece 10 . figure 1 The upper part in shows the completed state of the form rolling process. The pitch P1 of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com