A kind of deformation process of aluminum alloy S-shaped fin tube

A technology of aluminum alloy and finned tubes, which is applied in the field of deformation technology, can solve problems such as thick fins and large molds, and achieve the effects of optimizing material loss, optimizing heat transfer performance, and saving materials

Inactive Publication Date: 2011-12-28

史博鑫

View PDF6 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] In order to overcome the shortcomings of large mold and thick fins, the present invention provides a deformation process for producing aluminum alloy finned tubes

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

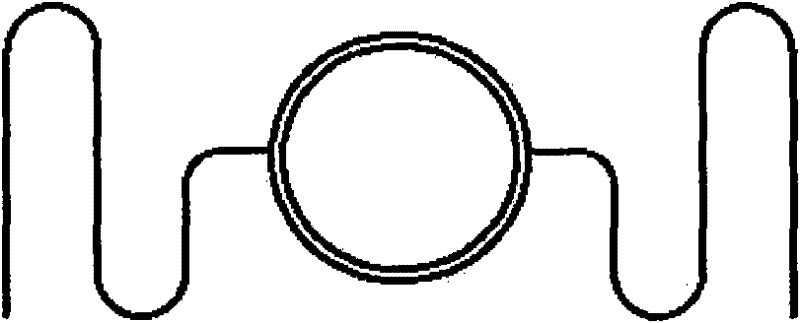

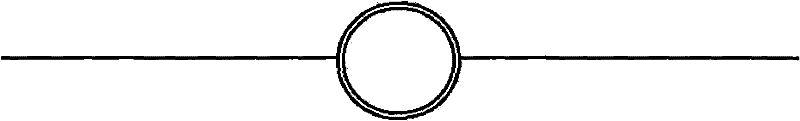

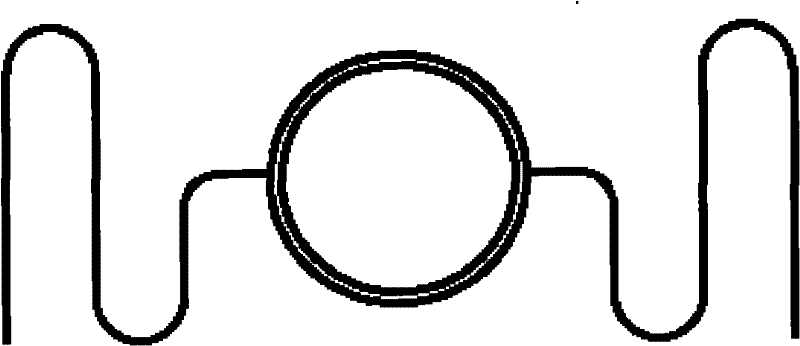

[0012] When the aluminum alloy fin tube reaches after extrusion figure 1 shape, and then use a special machine to flatten the fins of the fin tube until figure 2 shape.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

A deformation process for producing aluminum alloy finned tubes. The fins of the aluminum alloy fin tube are folded or curled during extrusion molding, and the fins are rolled flat by special machinery after extrusion. An airfoil with the same performance will use a smaller mold, so that the airfoil can be produced thinner and save material.

Description

Technical field [0001] The invention relates to a deformation process for producing an aluminum alloy fin tube. It is used for extruding aluminum alloy finned tubes by extruders. It belongs to the international patent class F28F3 / 00 "general heat exchange or parts of heat exchange equipment". Background technique [0002] At present, the production method of aluminum alloy finned tube is extrusion molding. During the forming process, the minimum thickness of the airfoil is related to the diameter of the mold. The minimum thickness of fins with larger molds is limited during production. For example, when making a single-sided fin of 90 mm according to the traditional process, the root is 1.5 mm and the end is about 1.0 mm. [0003] The optimal size of the theoretical calculation of the fins on the aluminum alloy finned tube used in the evaporator is 1 mm in thickness at the root and 0.3 mm in the end. Contents of the invention [0004] In order to overcome the disadvant...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B21D53/08B21D3/00

Inventor 史博鑫

Owner 史博鑫

Features

- Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com