An integrated treatment device and treatment process for exhaust gas containing dust and heat

A treatment device and treatment process technology, which is applied in the direction of combined devices, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of waste of resources and heat energy, environmental pollution, etc., and achieve reduced heat energy consumption, improved heat exchange efficiency, and reduced water volume Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

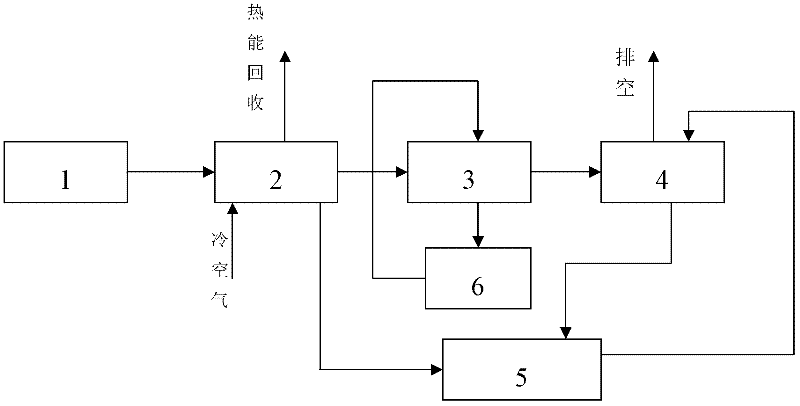

[0025] Such as figure 1 As shown, the dust-containing, humid-heat-containing exhaust gas integrated treatment device includes a dust removal device and a washing and absorption device, and the heat exchange equipment 2 is connected in series between the dust removal device 1 and the washing and absorption device 3 through pipelines. The liquid outlet of the heat exchange device 2 is connected to the circulating water tank 5 through a pipeline. The drain of the washing and absorbing device 3 is connected to the inlet of the circulating liquid tank 6 through a pipeline, and the outlet of the circulating liquid tank 6 is connected back to the second inlet of the washing and absorbing device 3 through a pipeline. That is, the circulating liquid tank 6 is connected with the washing and absorbing device 3 through pipelines to form a circulating loop. The exhaust port of the washing and absorbing device 3 is connected to the spray tower 4 through a pipeline. The spray tower 4 and t...

Embodiment 2

[0027] The process of using the dust-containing and humid-heat tail gas integrated treatment device of embodiment 1 for processing:

[0028] In the production process of sulfur-based compound fertilizer, the tail gas produced by the drying and granulation section: contains 2000ppm of ammonia and 16.3g / m of dust 3 And humidity (moisture content) 0.286kg water vapor / kg dry air, the temperature is 120~130℃, the exhaust gas flow rate is 1000m 3 / h.

[0029] a) Dust removal: the tail gas is passed into the diffusion cyclone dust collector 1 for dust removal, and the dust content of the tail gas after dust removal is 1.4g / m 3 , The dust removal efficiency is 92%, and the collected dust is returned to the production section as a material for reuse.

[0030] b) Heat exchange: The tail gas after dedusting is passed into the polytetrafluoroethylene shell and tube heat exchanger 2 for countercurrent heat exchange with the cold air to recover heat energy and reduce the temperature and h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dust removal efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com