Upright Vacuum Cleaner

A vacuum cleaner and upright technology, which is applied in the field of cyclone upright electric vacuum cleaners, and can solve problems such as dust contamination and dirty suction nozzles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

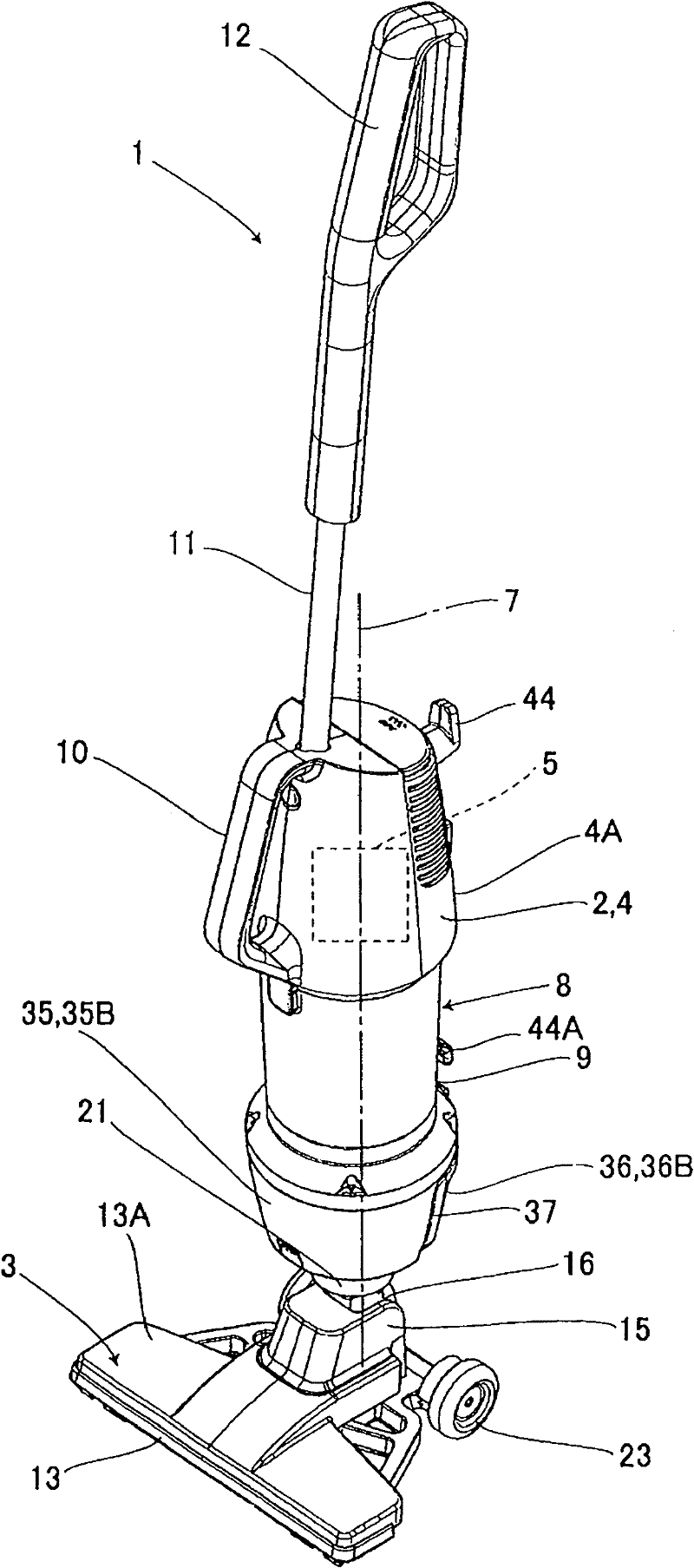

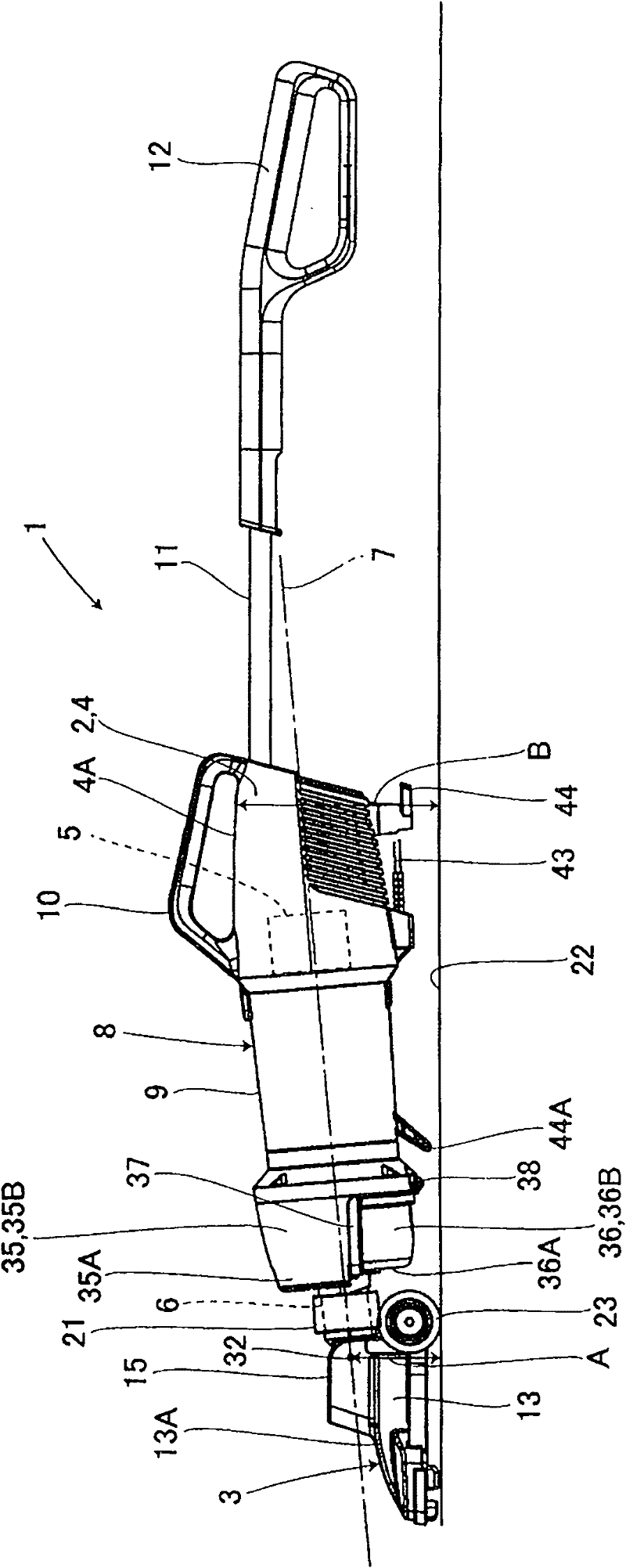

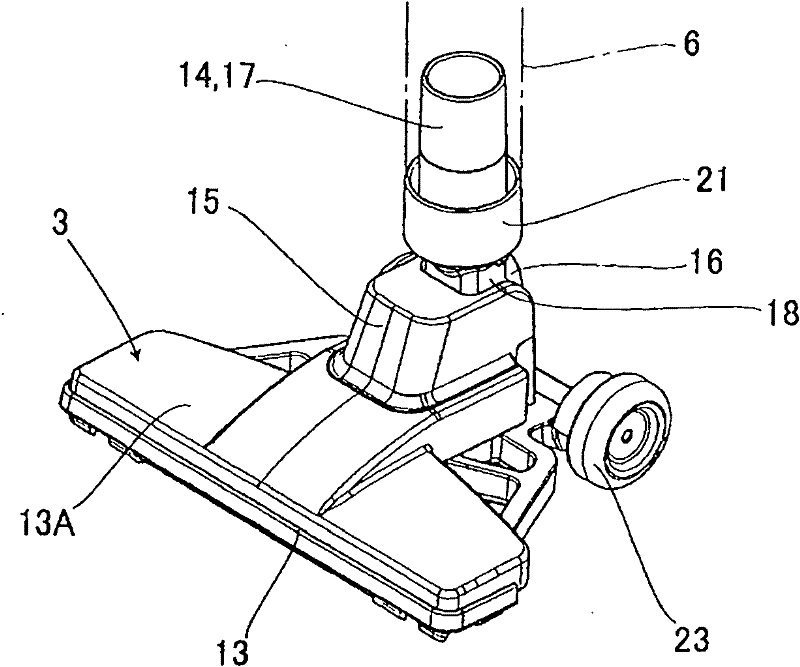

[0027] Embodiments of the present invention will be described below with reference to the drawings. like Figure 1~2 As shown, the upright electric vacuum cleaner 1 is constituted by having a vacuum cleaner main body 2 and a suction nozzle 3 detachably attached to the lower part of the vacuum cleaner main body 2 .

[0028] The said cleaner main body 2 is comprised by having the suction mechanism part 4 and the dust separation member 8 attached detachably with respect to this suction mechanism part 4. As shown in FIG. Said suction mechanism part 4 is comprised by having the electric blower 5 inside the substantially cylindrical casing 4A. Moreover, the receiving connection port 6 for connecting the said suction nozzle 3 is provided in the lower part of the said dust separation member 8 which comprises the said cleaner main body 2. As shown in FIG. The receiving connection port 6 is cylindrical, and its central axis 7 is arranged vertically. In addition, the dust separating m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com