A power quality conditioner for electrified railway

A technology of power quality and regulator, applied in the direction of transformer/inductor coil/winding/connection, reactive power adjustment/elimination/compensation, AC network to reduce harmonic/ripple, etc., which can solve the limited effect of negative sequence compensation , Transformer complex process, too many windings and other problems, to achieve the effect of simple control, good harmonic current suppression characteristics and dynamic response characteristics, and improve control accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

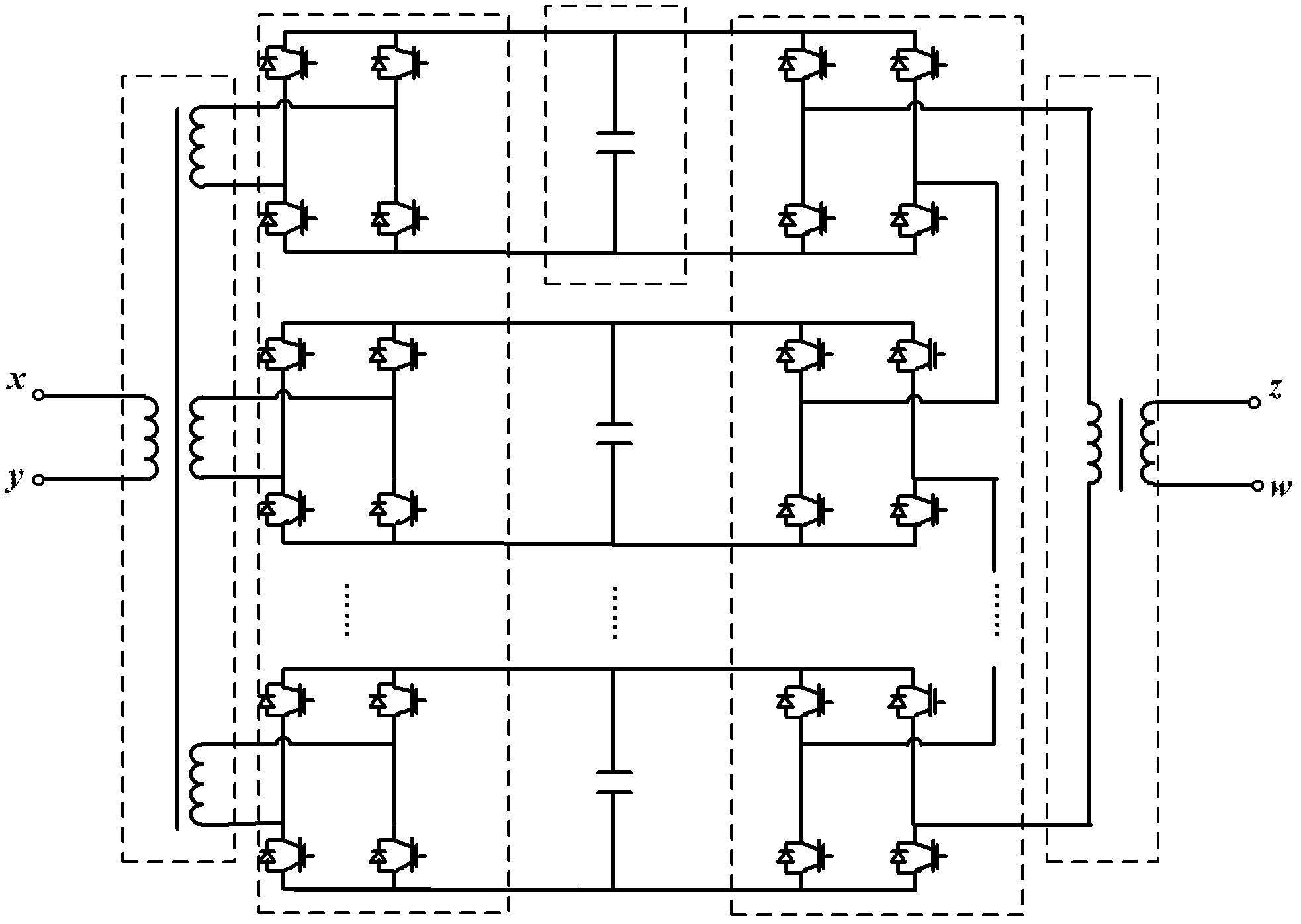

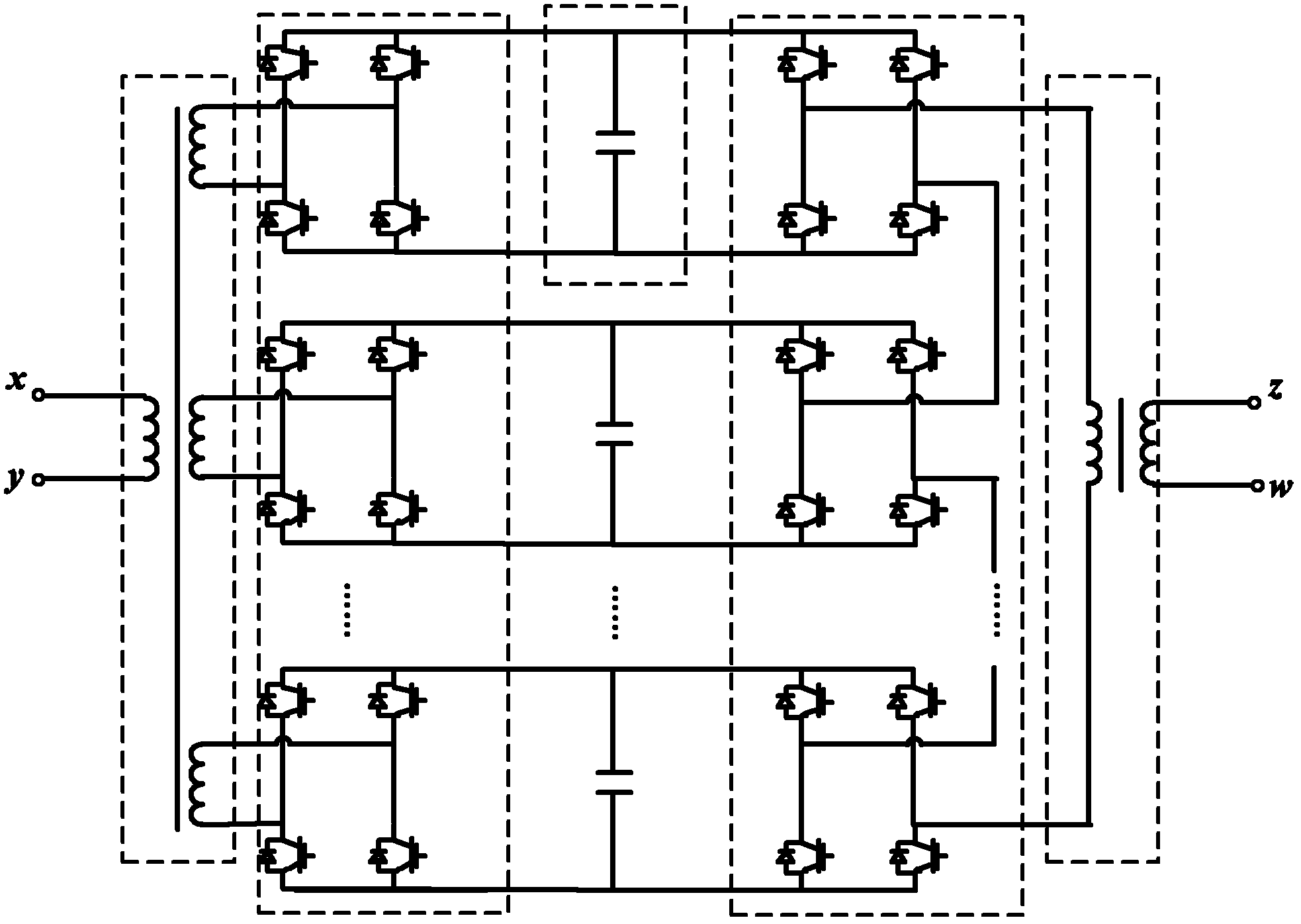

[0022] As shown in Figure 1, a kind of power quality conditioner of electrified railway comprises single-phase multi-winding transformer, single-phase single-winding transformer, converter (I, II) and capacitor;

[0023] The device of this embodiment uses a single-phase multi-winding transformer to realize the parallel connection and electrical isolation functions of multiple voltage source converters. The single-phase multi-winding transformer is composed of a primary winding and m secondary windings; the secondary windings are connected in parallel;

[0024] A single-phase single-winding transformer consists of a primary winding and a secondary winding;

[0025] Both converter I and converter II are voltage source converters, and each voltage source converter adopts a single-phase two-level H bridge arm structure, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com