A Lens Design Method for Square Uniform Light Spot

A lens design and square technology, which is applied in the field of lens design where the illuminated surface is a square uniform light spot, can solve the problems of uneven illumination of the illuminated surface and difficulty in meeting customer requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific design steps of this design method will be described in detail below through graphic and text descriptions.

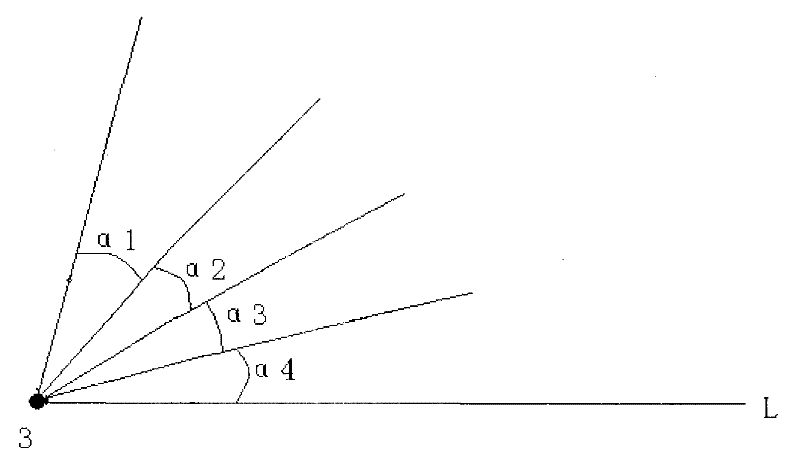

[0027] Such as figure 1 As shown, the square spot is first divided into eight centrally symmetrical areas with an angle of 45 degrees along the axis of symmetry, and one of the areas 10 is used as the design object of the present invention, and the following design steps are all completed in this area 10. The region 10 is divided into n (n≥2) corner regions. For the sake of clarity in the illustration, this embodiment is divided into three corner regions, the included angles are γ1, γ2, and γ3, and the corners are 11 and γ3 respectively. 22, 22 and 33, 33 and 44, the length difference between the two sides of each included angle is d.

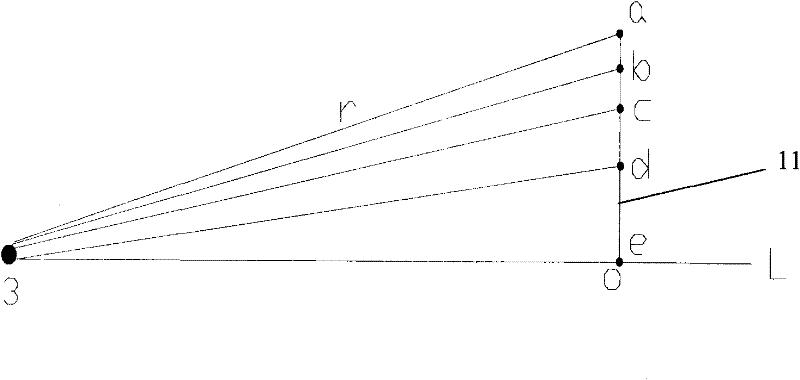

[0028] Such as figure 2 As shown, starting from the corner area with an included angle γ1, the plane passing through one of its corner sides 11 and the optical axis L of the light source 3 is the first incident pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com