A small high-speed centrifugal pump suitable for wide-range flow regulation

A technology of flow regulation and high-speed centrifugation, which is applied to components, pumps, and pump components of pumping devices used for elastic fluids. It can solve the problems of centrifugal pump anti-cavitation performance limiting rotor dynamics, etc., and achieve excellent anti-cavitation Performance, improve anti-cavitation performance, avoid cavitation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

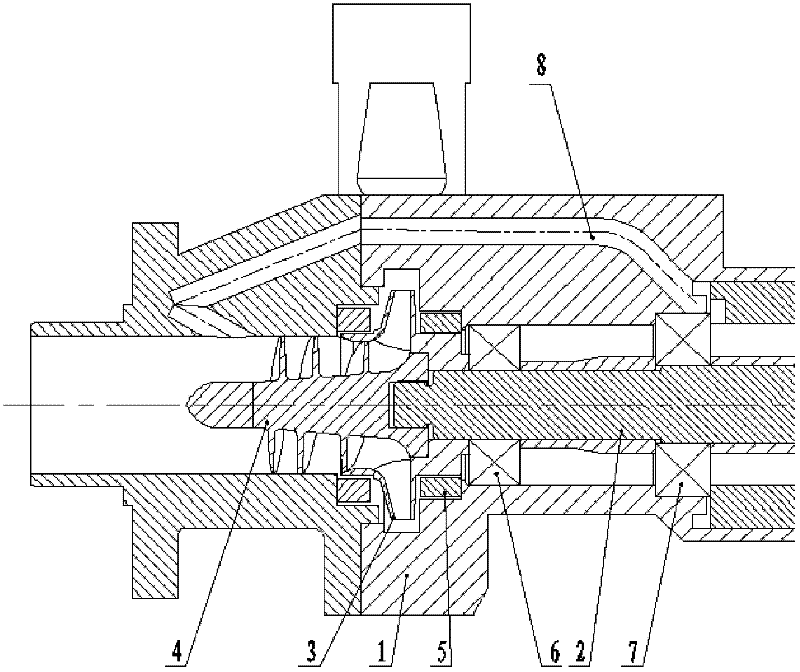

[0030] figure 1 It is a schematic diagram of a centrifugal pump device suitable for wide-range flow regulation, including a pump body 1, a shaft arranged in the pump body through bearings (6, 7), a centrifugal wheel, and an induction wheel. The front end of the pump body is provided with a liquid inlet. The side is provided with a liquid outlet. The shaft is connected to the pump body through bearings, and the centrifugal wheel and the induction wheel are installed at one end of the shaft in turn, fixedly connected with the shaft through a key, and rotate together. The other end of the shaft is equipped with a driving machine (motor or turbine), and the power of the driving machine is transmitted to the centrifugal wheel and the induction wheel through the shaft, so as to increase the pressure of the medium (fuel). The device has the characteristics of compact structure, high design speed, high performance and high anti-cavitation performance.

[0031] The above-mentioned ce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com