A method and device for cracking and reducing viscosity of salt-containing heavy oil collected and transported on the surface of an oil field

A heavy oil and oilfield technology, which is applied in the direction of earthwork drilling, production fluid, wellbore/well components, etc., can solve the problems that the salt content cannot meet the requirements of catalytic cracking, crude oil desalination treatment, heavy dependence on thin oil resources, etc., to achieve convenience On-site application, reasonable structure and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

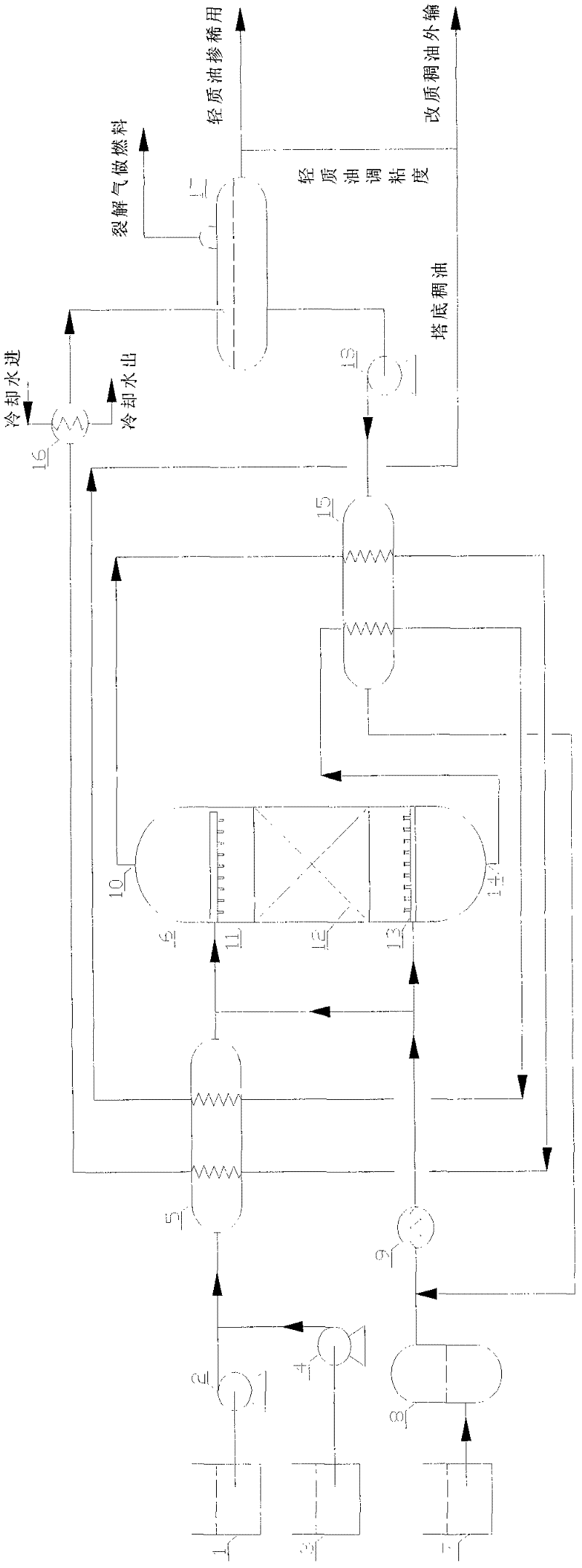

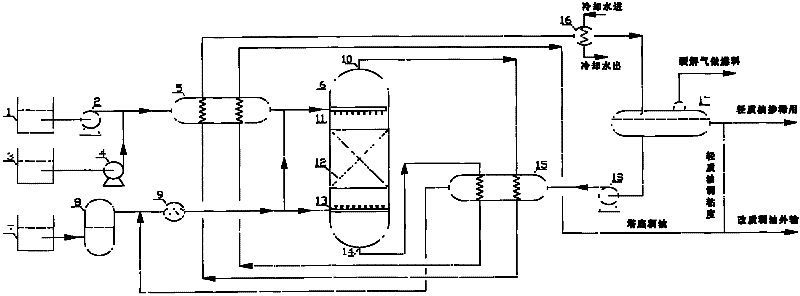

[0016] In order to further disclose the technical solutions of the present invention, the following will be described in detail through examples in conjunction with the accompanying drawings:

[0017] The present invention uses superheated steam within a certain temperature range to carry out catalytic cracking and separation of salt-containing heavy oil, controls the reaction temperature through the preheating temperature and the flow rate of superheated steam, and controls the residence time through the flow rate of heavy oil. Crack the heavy oil internally to reduce the viscosity, recycle the cracked gas and condensed water, and mix the heavy oil at the bottom of the tower with the cracked (partial) light hydrocarbons to obtain the modified heavy oil. According to the viscosity requirements of the modified heavy oil Determine the mixing ratio of light hydrocarbons, and reduce the energy consumption of heavy oil cracking and viscosity reduction through the comprehensive utili...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com