Variable-burning-rate synergistic perforating propellant

A technology of charging and burning rate, which is applied in the direction of mining fluid, wellbore/well components, earthwork drilling and mining, etc. It can solve the problems of unreasonable charging structure, insufficient ignition, incomplete combustion, etc., and achieve the detonation time Long-lasting, less prone to accidents, and low ignition energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

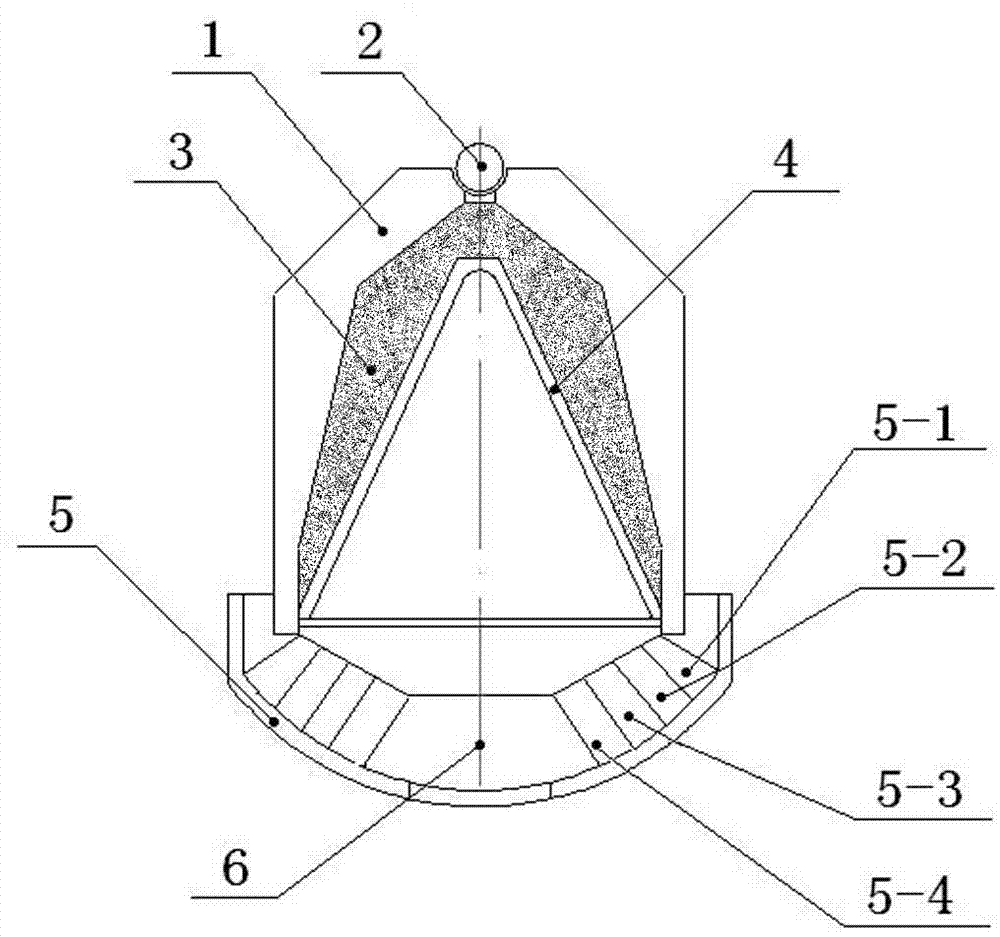

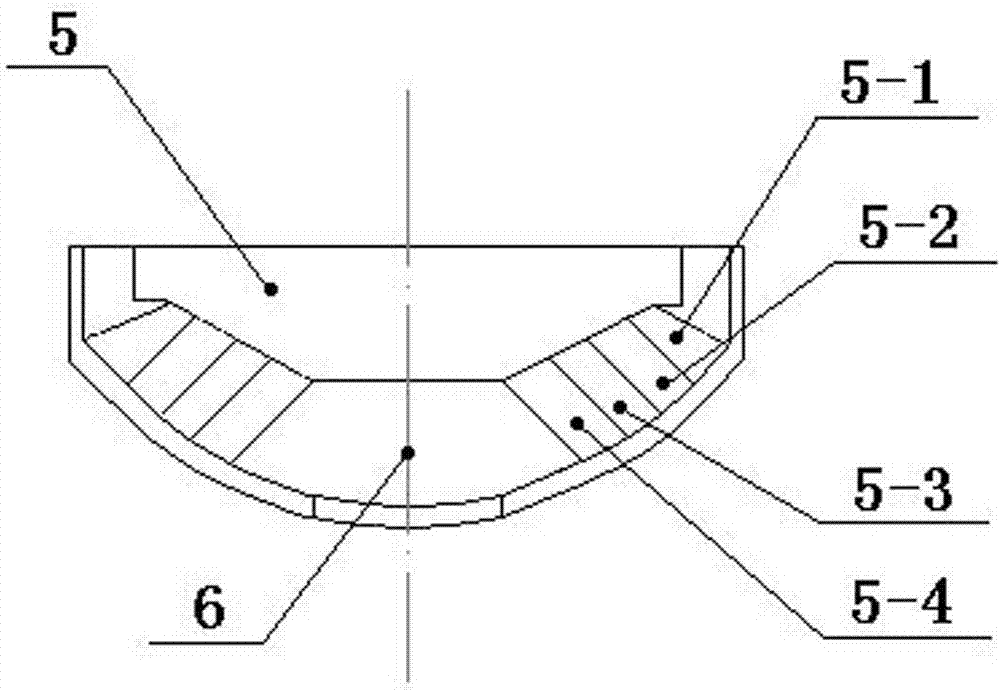

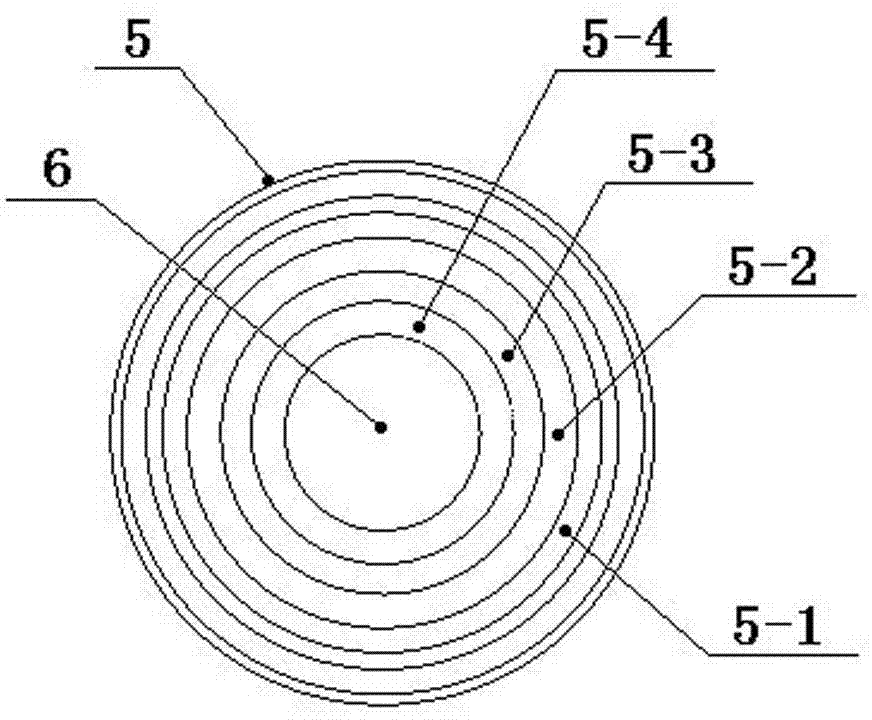

[0017] A variable-burning rate-increasing efficiency perforating charge includes a perforating bomb and a charge front compartment 5. The perforating bomb includes a bomb case with a detonating cord 2 on the top, a charge type cover 4 arranged inside the bomb case 1, and a filler For the high-energy explosive 3 installed between the cartridge case 1 and the charge type cover 4, the charge front compartment 5 is tightly sleeved on the port of the inner cavity of the perforating bomb. The center of the concave bottom plate of the charge front compartment 5 is provided with a perforation The jet channel 6 communicates with the inner cavity of the projectile, and the centerline of the cartridge case 1, the charge type cover 4 and the jet channel 6 are on the same axis; wherein, the interior of the charge front compartment 5 is from the periphery to the jet channel 6 To the bottom, there are circular ring-shaped ignition ring 5-1, delay ring 5-2, speed increasing ring 5-3 and deflagr...

Embodiment 2

[0020] A variable-burning rate-increasing efficiency perforating charge includes a perforating bomb and a charge front compartment 5. The perforating bomb includes a bomb case with a detonating cord 2 on the top, a charge type cover 4 arranged inside the bomb case 1, and a filler For the high-energy explosive 3 installed between the cartridge case 1 and the charge type cover 4, the charge front compartment 5 is tightly sleeved on the port of the inner cavity of the perforating bomb. The center of the concave bottom plate of the charge front compartment 5 is provided with a perforation The jet channel 6 communicates with the inner cavity of the projectile, and the centerline of the cartridge case 1, the charge type cover 4 and the jet channel 6 are on the same axis; wherein, the interior of the charge front compartment 5 is from the periphery to the jet channel 6 To the bottom, there are circular ring-shaped ignition ring 5-1, delay ring 5-2, speed increasing ring 5-3 and deflagr...

Embodiment 3

[0023] A variable-burning rate-increasing efficiency perforating charge includes a perforating bomb and a charge front compartment 5. The perforating bomb includes a bomb case with a detonating cord 2 on the top, a charge type cover 4 arranged inside the bomb case 1, and a filler For the high-energy explosive 3 installed between the cartridge case 1 and the charge type cover 4, the charge front compartment 5 is tightly sleeved on the port of the inner cavity of the perforating bomb. The center of the concave bottom plate of the charge front compartment 5 is provided with a perforation The jet channel 6 communicates with the inner cavity of the projectile, and the centerline of the cartridge case 1, the charge type cover 4 and the jet channel 6 are on the same axis; wherein, the interior of the charge front compartment 5 is from the periphery to the jet channel 6 To the bottom, there are circular ring-shaped ignition ring 5-1, delay ring 5-2, speed increasing ring 5-3 and deflagr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com