Photo-fermentation anaerobic fluidized bed hydrogen production reactor

An anaerobic fluidized bed and reactor technology, applied in photobioreactors, gas production bioreactors, biochemical instruments, etc., can solve the problems of low utilization rate of light energy, easy loss of biomass, etc. Quantity, avoid the loss of bacteria, reduce the effect of shading effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

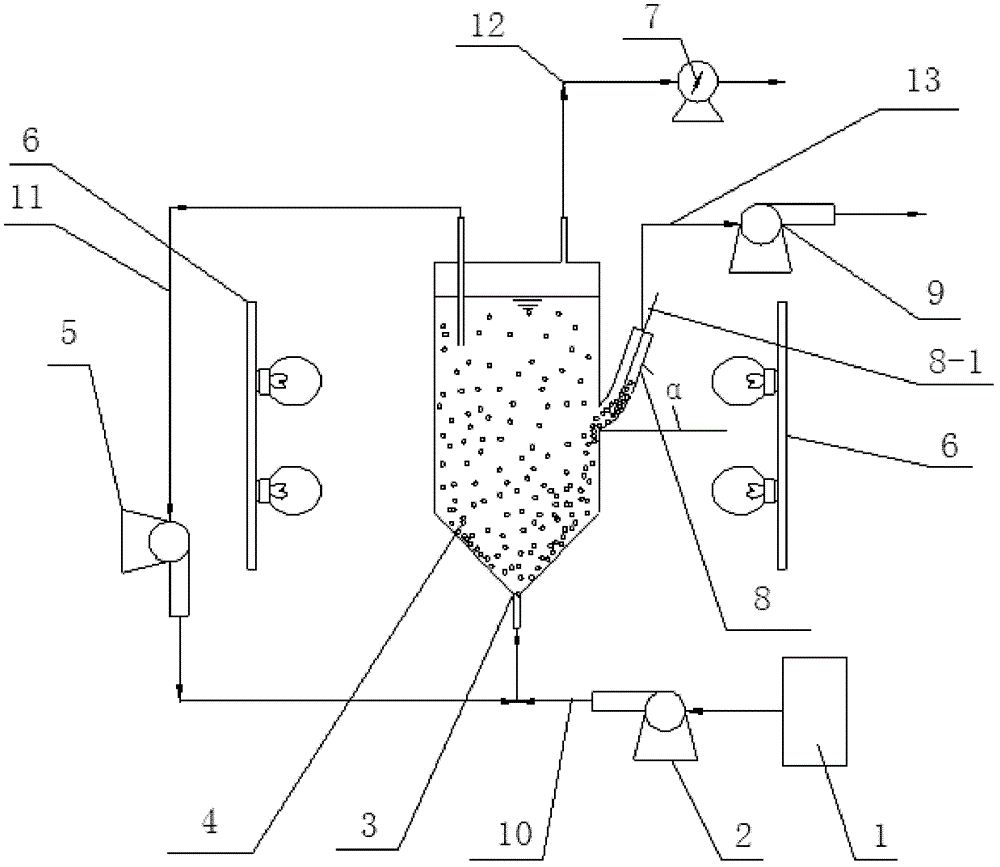

[0009] Specific implementation mode one: combine figure 1 To illustrate this embodiment, the photofermentation anaerobic fluidized bed hydrogen production reactor of this embodiment includes a water inlet tank 1, a water inlet pump 2, a reactor body 3, a gas flow meter 7, a water inlet pipe 10, a gas outflow pipe 12 and two A group of lighting systems 6, a group of lighting systems 6 are respectively arranged on the left and right sides of the reactor body 3, the bottom of the reactor body 3 communicates with the water inlet tank 1 through the water inlet pipe 10, and the water inlet pump 2 is installed on the water inlet pipe 10, and the reaction A gas outflow pipe 12 is installed on the upper cover of the device main body 3, and the gas flow meter 7 is installed on the gas outflow pipe 12;

[0010] The photofermentation anaerobic fluidized bed hydrogen production reactor also includes an activated carbon fiber adsorption carrier 4, a return pump 5, a single pipe 8 in the sed...

specific Embodiment approach 2

[0011] Specific implementation mode two: combination figure 1 Describe this embodiment, the carbon fiber specific surface area of the activated carbon fiber adsorption carrier 4 of this embodiment is 1500m 2 / g, the micropore radius is Total pore volume 705±15×10 -3 ml / g, the length of chopped strands is 0.1mm. In this way, the photofermentation bacteria are adsorbed on the outer surface of the carbon fiber, so that the photofermentation bacteria can receive light more effectively. When the light propagates to the surface of the activated carbon fiber, the light energy is fully absorbed and utilized by the photofermentation bacteria adsorbed on the outer surface of the carrier. , therefore, the utilization rate of light energy is improved more effectively. Other compositions and connections are the same as in the first embodiment.

specific Embodiment approach 3

[0012] Specific implementation mode three: combination figure 1 The present embodiment will be described. The reflux pump 5 of the present embodiment adopts a reflux pump with a flow rate of 150 ml / min. With such a setting, the carrier is in a suspended fluidized state, with good mass transfer conditions, and the microorganisms are easy to fully contact with the wastewater, and each photofermentation bacteria adsorbed on the surface of the carrier can receive light and produce hydrogen, effectively improving the Light energy utilization efficiency of photofermentation hydrogen production reactor. Other compositions and connections are the same as those in Embodiment 1 or Embodiment 2.

[0013] Specific implementation mode four: combination figure 1 To illustrate this embodiment, the lighting system 6 of this embodiment adopts an incandescent lighting system, and the average light intensity is controlled to be 4000 lx. Such setting can effectively provide sufficient light en...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com