Pigment composition for children's painting and preparation method

A pigment composition and painting technology, applied in the field of painting supplies, can solve the problems affecting the appearance and shelf life of products, insolubility of fillers and pigments, and unsmooth product coating, and achieve bright colors, small dosage, and smooth product coating. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

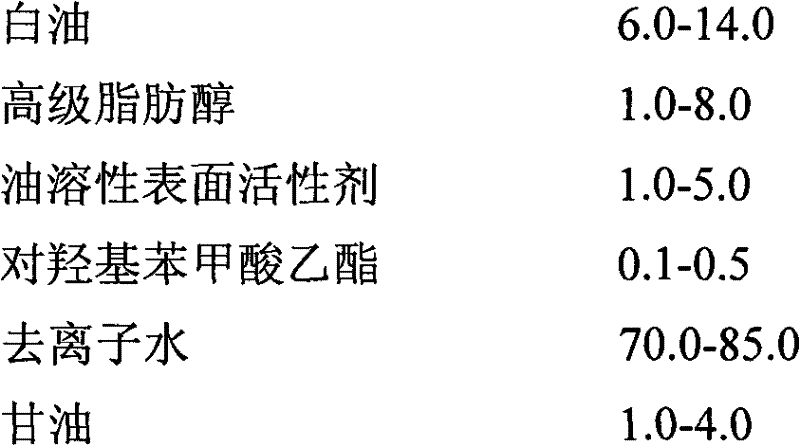

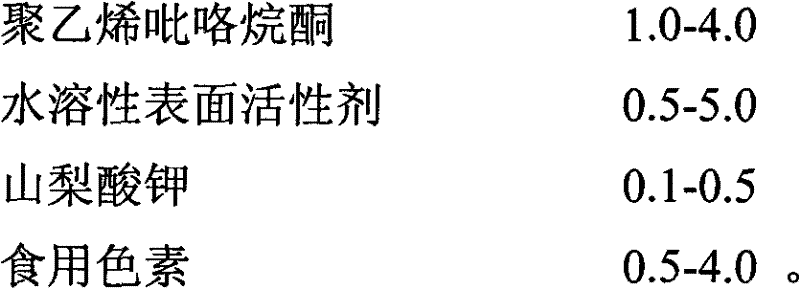

Method used

Image

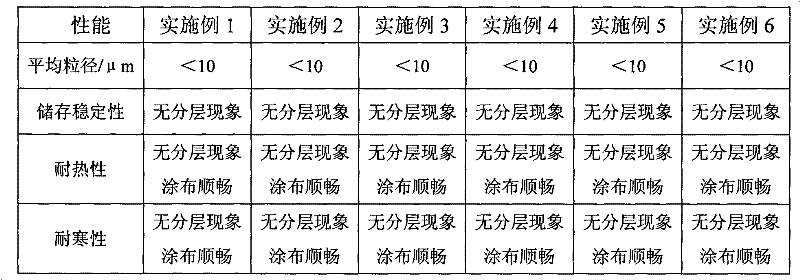

Examples

Embodiment 1

[0026] Put 12.0 parts by weight of white oil, 2.0 parts by weight of cetyl alcohol, 1.2 parts by weight of sorbitan monooleate (Span-80) and 0.2 parts by weight of ethyl p-hydroxybenzoate into a stirring tank, and heat to 60~ 70°C, stir until it dissolves evenly to obtain the oil phase material; add 77.6 parts by weight of deionized water to another stirred tank, and add 2.0 parts by weight of glycerin, 2.0 parts by weight of polyvinylpyrrolidone (K-85), 2.3 parts by weight of Polyoxyethylene sorbitan monooleate (Tween-80), 0.2 parts by weight of potassium sorbate, heated to 60-70 ° C, after being uniformly dissolved, adding 0.5 parts by weight of food coloring tartrazine, and dissolving uniformly to obtain water Phase material; under stirring, add the water phase material to the oil phase material, keep the temperature at 60-70°C, emulsify evenly, and cool to room temperature to obtain light yellow children's paint.

Embodiment 2

[0028] 9.0 parts by weight of white oil, 6.0 parts by weight of lauryl alcohol, 1.0 parts by weight of sorbitan monostearate (Span-60) and 0.1 parts by weight of ethyl p-hydroxybenzoate are put into a stirring tank and heated to 60 ~70°C, stir until it dissolves evenly to obtain the oil phase material; add 75.1 parts by weight of deionized water to another stirred tank, and add 3.0 parts by weight of glycerin, 2.0 parts by weight of polyvinylpyrrolidone (K-85), 2.8 parts by weight of 1 part of polyoxyethylene sorbitan monostearate (Tween-60), 0.2 parts by weight of potassium sorbate, heated to 60-70 ° C, after being dissolved evenly, 0.8 parts by weight of food coloring carmine was added, and the solution was uniform. Obtain the water-phase material; under stirring, add the water-phase material to the oil-phase material, keep the temperature at 60-70°C, emulsify evenly, and cool to room temperature to obtain red children's paint.

Embodiment 3

[0030] Put 12.0 parts by weight of white oil, 2.0 parts by weight of stearyl alcohol, 2.8 parts by weight of glycerol monostearate and 0.2 parts by weight of ethyl p-hydroxybenzoate into a stirring tank, heat it to 60-70 °C, and stir until it dissolves evenly , to obtain the oil phase material; add 76.0 parts by weight of deionized water in another stirred tank, under stirring, add 3.0 parts by weight of glycerin, 2.0 parts by weight of polyvinylpyrrolidone (K-85), 0.8 parts by weight of sodium lauryl sulfate, 0.2 parts by weight of potassium sorbate, heated to 60-70 °C, after being uniformly dissolved, adding 1.0 parts by weight of food coloring bright blue, dissolved evenly, to obtain the water phase material; under stirring, add the water phase material to the oil phase material, Keep the temperature at 60-70°C, emulsify evenly, and cool to room temperature to obtain blue children's paint.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com