Plastic packaging film processing method and system

A plastic packaging and film processing technology, which is applied in the field of plastic film processing, can solve problems such as poor opening and insufficient smoothness of plastic packaging films, and achieve good opening, reduce labor intensity, and reduce costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

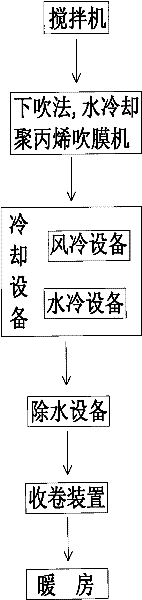

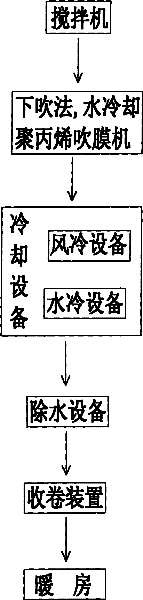

[0029] refer to figure 1 , the plastic packaging film processing system includes a mixer, down-blown water-cooled polypropylene film blowing machine, air-cooled equipment and water-cooled equipment, extrusion-type water removal equipment mainly composed of pressure rollers, winding devices and temperature control equipment conservatory.

[0030] The process flow of this plastic packaging film processing system is roughly as follows: polypropylene raw material → put into the mixer → add an appropriate amount of opening agent → stir evenly → add down blowing method, water cooling polypropylene film blowing machine → come out of the film from the grinding head → pass through the wind Cooling → water cooling → press water roller + processing → winding the finished film → put it in a warm room with a temperature controlled at 15°C to 80°C for more than 10 hours.

[0031] Specifically, the polypropylene raw material is added with an appropriate amount of opening agent, stirred even...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com