Devices for monitoring welding parameters

A technology of welding parameters and welding machines, applied in auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve problems affecting welding quality, achieve the effect of improving quality and preserving traceability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

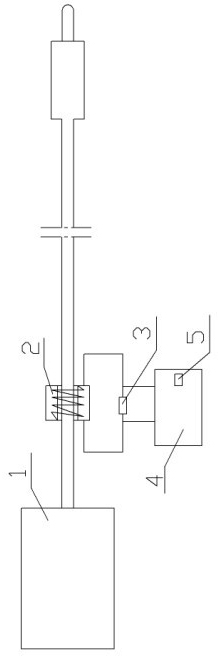

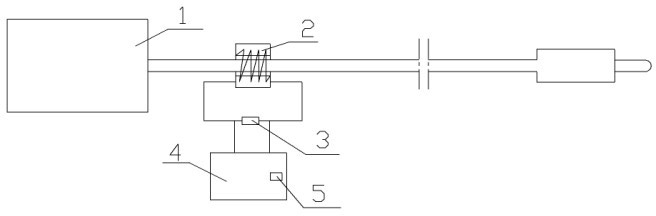

[0009] Accompanying drawing is an embodiment of the present invention, present embodiment is specifically described in conjunction with accompanying drawing, comprises current transformer 2, resistance 3, card reader 4 and smart card 5, and current transformer 2 is arranged on the welding torch output line of welding machine 1 Above, the resistor 3 is set to be connected in series with the current transformer 2, the input end of the card reader 4 is set to be connected to both ends of the resistor 3, and the smart card 5 is installed in the card reader 4.

[0010] In this embodiment, the smart card 5 is set as a CF card, and the model of the card reader 4 is Sandisk400X.

[0011] When using this embodiment, the welding machine 1 is started to work, and during the welding process, the current through the output line of the welding torch of the welding machine 1 is sensed by the current transformer 2, and the signal of the voltage value is output by the resistor 3, and passed thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com