Lathe four-jaw clamp three-jaw clamping system

A technology of three-jaw clamps and lathes, which is applied in the direction of chucks, etc., can solve the problems of high clamping efficiency, large clamping force of four-jaw chucks, and high requirements for clamping precision, so as to save production input costs and achieve stable and reliable clamping force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

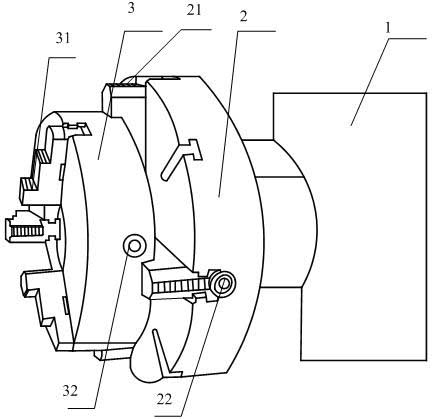

[0030] like figure 1 As shown, the lathe four-jaw clamp and three-jaw clamping system mainly includes a lathe, the lathe 1 is connected with a four-jaw chuck 2 , and the end of the four-jaw chuck 2 far away from the lathe 1 is connected with a three-jaw chuck 3 .

[0031] The end of the four-jaw chuck 2 away from the lathe 1 is provided with at least four clamping jaws 21 .

[0032] The clamping claws 21 are evenly distributed on the circumference of the four-jaw chuck 2 and clamped to the body of the three-jaw chuck 3 .

[0033] The side wall of the four-jaw chuck 2 is provided with tightening screws 22 , and the tightening screws 22 are connected with the clamping jaws 21 .

[0034] The end of the three-jaw chuck 3 away from the four-jaw chuck 2 is provided with at least three holding jaws 31 .

[0035] The side wall of the three-jaw chuck 3 is provided with fastening screws 32 , and the fastening screws 32 are connected with the holding claws 31 .

[0036] The four-jaw c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com