Adjustable Z-shaped offset bending mold

A bending mold, adjustable technology, applied in the field of sheet metal bending molds, can solve problems such as complex structure, lower production efficiency, and higher mold processing costs, and achieve the effects of reducing use costs, reducing processing time, and reducing processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

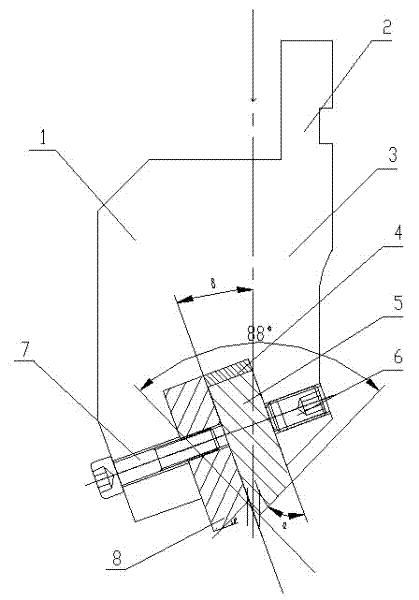

[0013] From Figure 1-Figure 3It can be seen from the figure that: an adjustable Z-shaped gap bending die is characterized in that: the adjustable Z-shaped gap bending die is mainly composed of an upper die 1 and a lower die 13, and the upper die 1 is mainly composed of an upper die Seat 3, upper fixed die 8, upper adjustable die 5, upper combined gasket 4, upper fixed bolt 7 and set screw 6, and lower die 13 is mainly composed of lower die base 14, lower fixed die 9, The lower adjustable die 10 and the lower fixing bolt 11 are composed. The upper mold base 3 is a long mold base with a cross-section that is arranged in the front and back directions and is a unequal rectangle. The upper part of the right side of the upper mold base 3 is vertically The cross-section of the device is rectangular and there is a clamping plate 2 with a rectangular long slot forward and backward. The plate 2 is a standard structure connecting the bending die and the machine tool slider plate, and c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com