A Method for Accurately Controlling the Curing Time of Tobacco Leaves in Intensive Barns

A dense baking room and baking time technology, applied in the direction of simultaneous control of multiple variables, non-electric variable control, control/regulation system, etc., can solve the problem of difficult baking time, no quantitative guidance, temperature and humidity, and difficult baking time To achieve accurate grasp and other issues, to achieve the effect of accurate implementation of baking technology and standardized baking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention is described in further detail below in conjunction with embodiment.

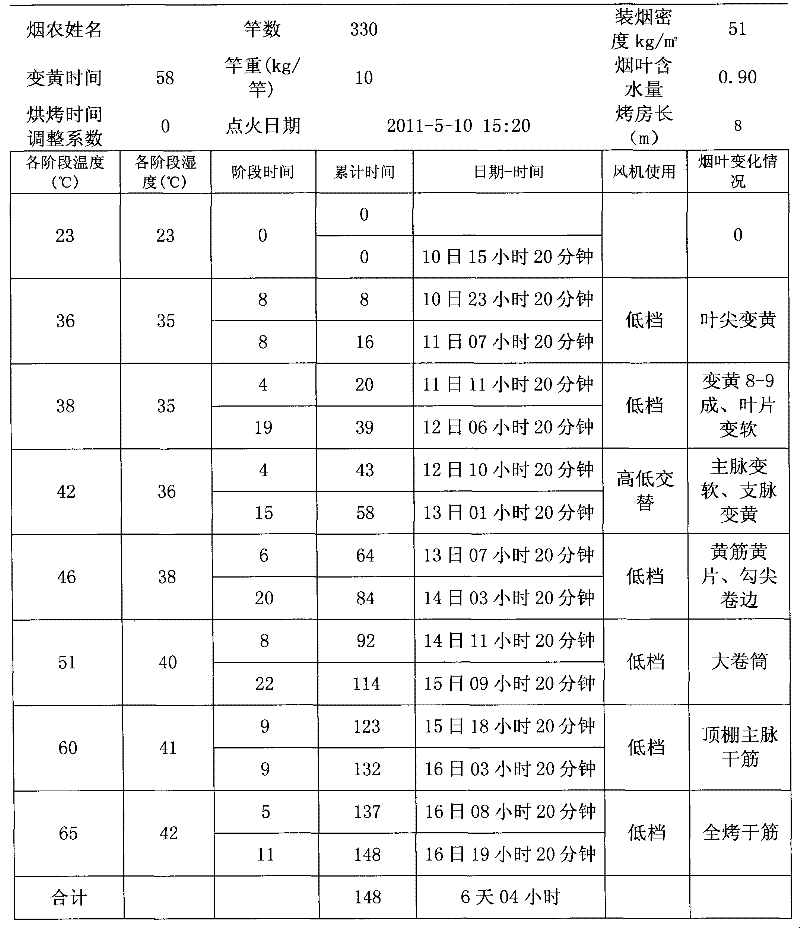

[0038] A method for precisely controlling the curing time of tobacco leaves in dense curing rooms, taking tobacco K326 variety as an example, the specific steps are as follows:

[0039] 1. Before each roasting, take 5-10 rods of fresh tobacco leaves for weighing, take the average weight of 5-10 rods of fresh tobacco leaves, count the number of tobacco rods of all flue-cured tobacco after roasting, and automatically calculate the amount of tobacco loaded , Smoke density, for example, taking the K326 variety as an example, the specific roasting times can be divided into: the first roasting method of the K326 variety in the large-scale intensive curing room, the second roasting method of the second-baking and the second shed leaf roasting of the K326 variety in the large-scale intensive curing room Method, roasting method of third roasting lower and middle leaves of K326 variety in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com