Adjustable rotary oblique-cutting automatic grafting device and method

An automatic grafting and adjustable technology, applied in the fields of botanical equipment and methods, horticulture, application, etc., can solve the problems of complex grafting machine structure, unsatisfactory grafting effect, easy falling off of scions, etc. handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

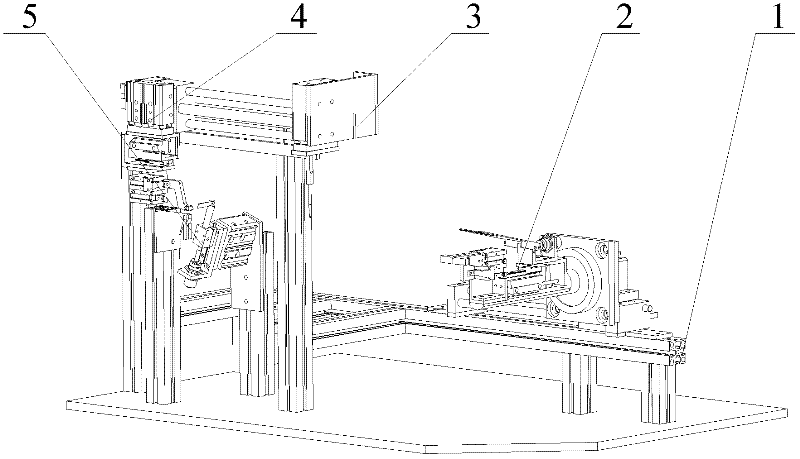

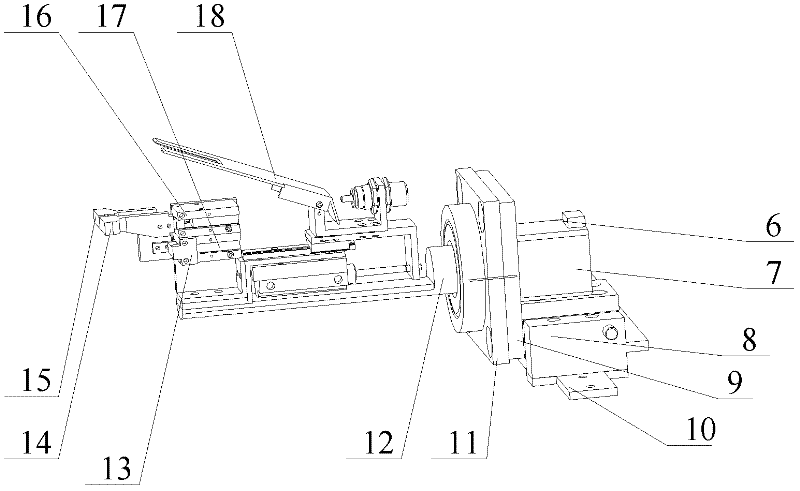

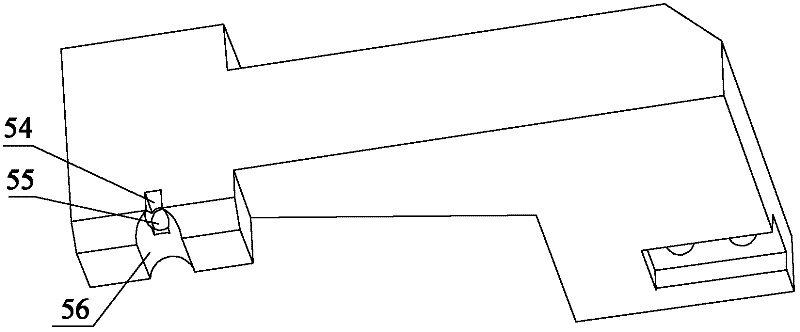

[0056] Figure 1 to Figure 8 Shows the specific structural schematic diagram of this embodiment, such as figure 1As shown, the adjustable rotary oblique insertion automatic grafting device includes a workbench, a frame 1, and a scion clamping and conveying mechanism 4, a scion cutting mechanism 5, a rootstock punching mechanism 3 and a rootstock clamping and conveying mechanism arranged in sequence from left to right. Mechanism 2, described scion clamping and conveying mechanism 4 comprises the scion clamping drive mechanism, the scion air claw and the scion chuck connected successively from top to bottom, and the described scion clamping drive mechanism is connected on the workbench by frame 1; Described scion cutting mechanism 5 comprises scion cutting drive mechanism, cutter mechanism and scion cutting positioning block 48, and scion cutting driving mechanism is connected with cutter mechanism, and scion cutting positioning block 48 is located at the front side of cutter me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com