A robot for measuring verticality and gauge of elevator guide rails

A technology for measuring robots and elevator guide rails, which is applied to measuring devices, instruments, and optical devices, etc. It can solve problems such as uncontrollable measurement errors, limited use range, and inability to detect and correct the guide rails of measuring instruments, so as to reduce production costs. Avoid the waste of manpower and material resources, the effect of installation and maintenance guarantee

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in detail below in conjunction with the embodiments and accompanying drawings. The examples are only used to describe the present invention in detail, and do not limit the protection scope of the claims of the present application.

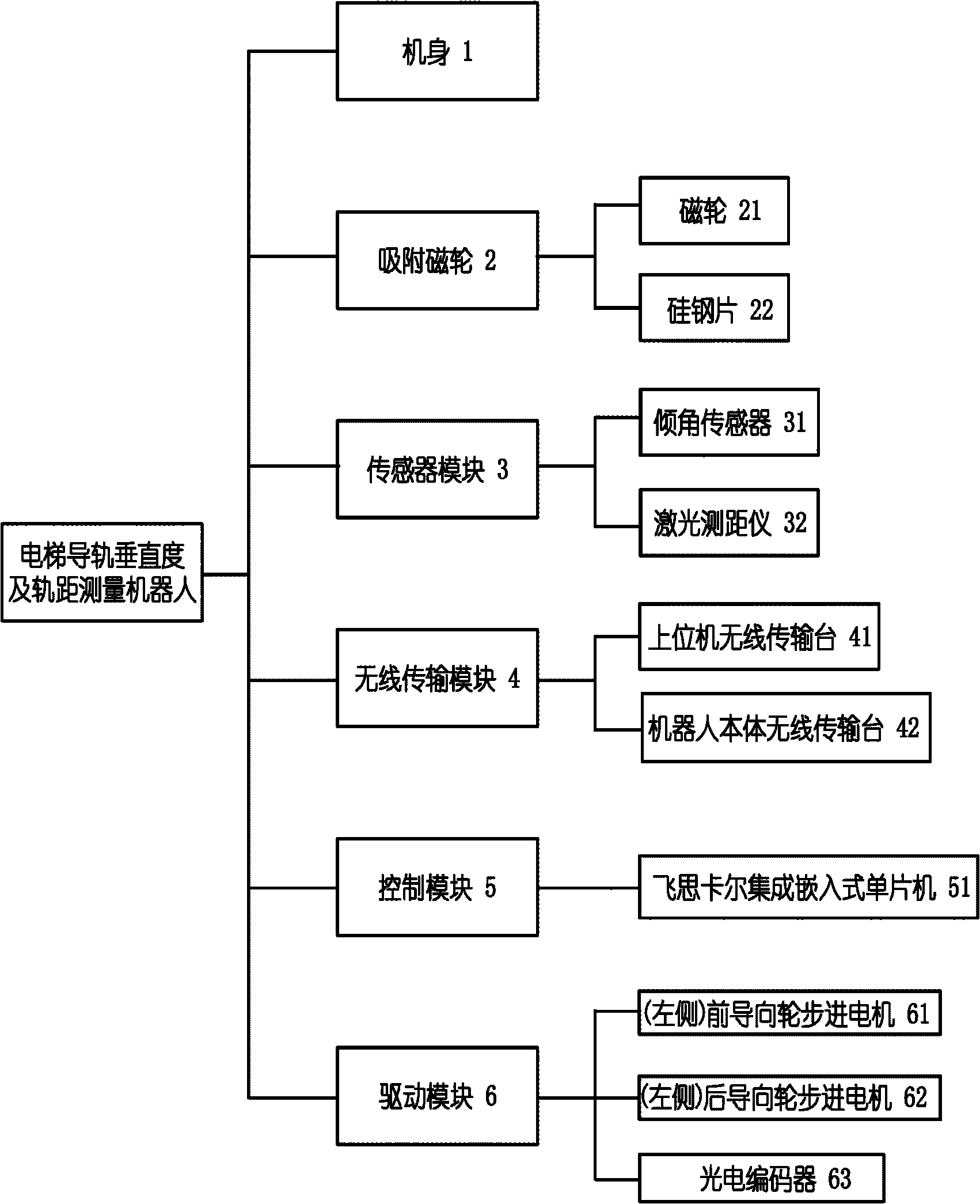

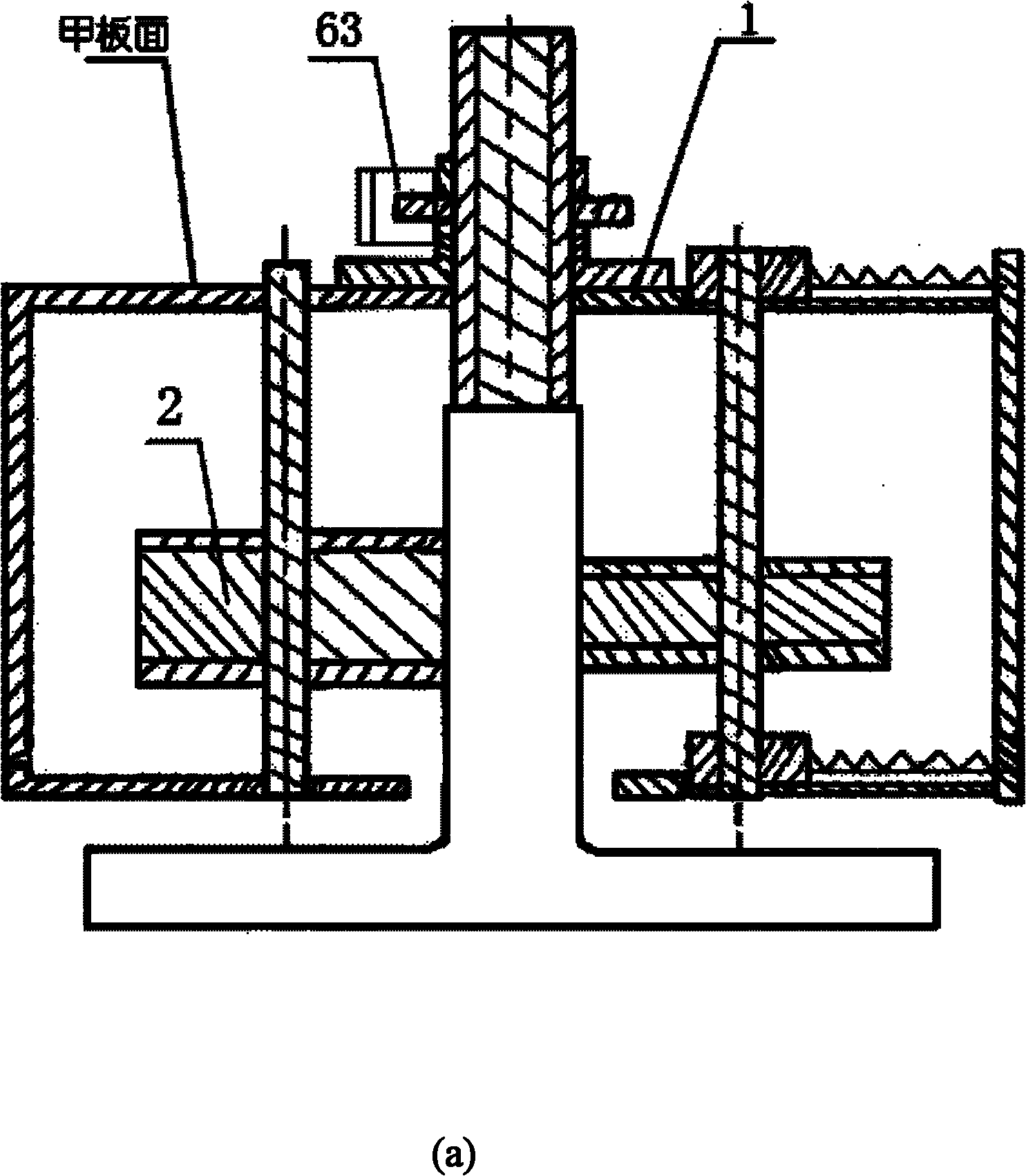

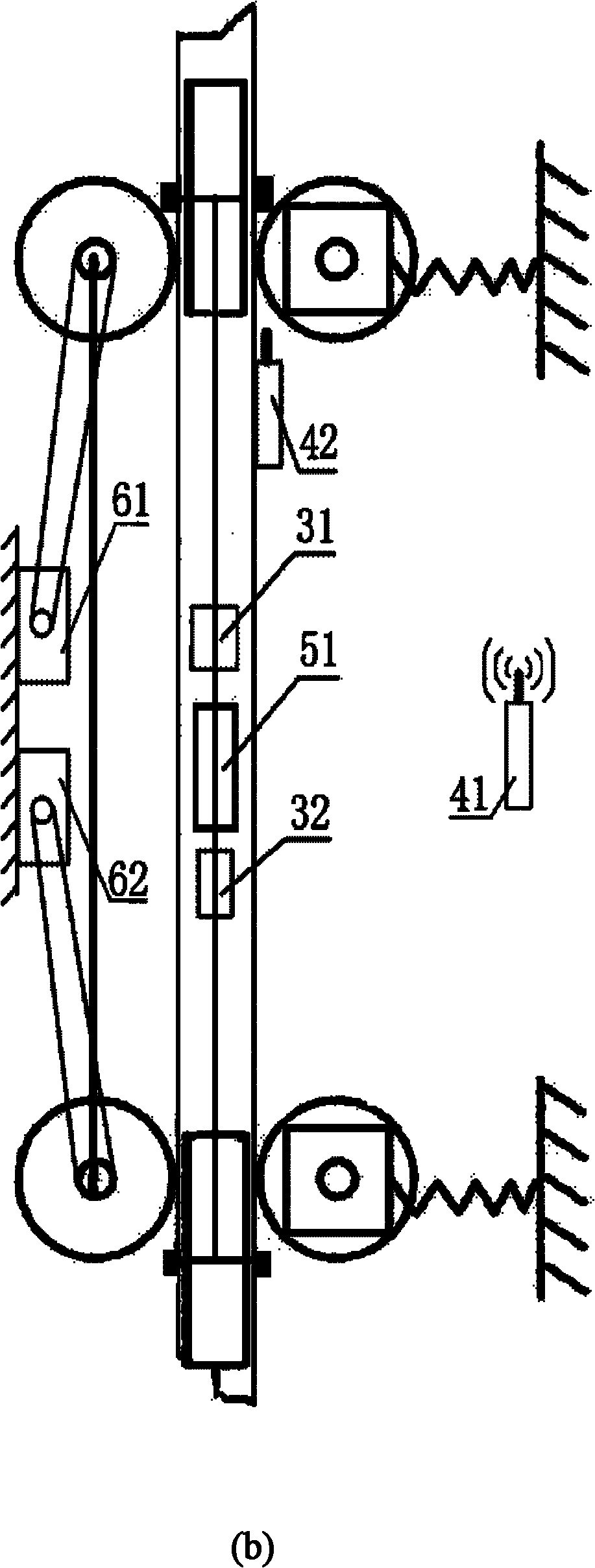

[0016] The elevator guide rail perpendicularity of the present invention design and gauge measuring robot are characterized in that this robot comprises fuselage 1, adsorption magnetic wheel 2, sensor module 3, wireless transmission module 4, control module 5 and driving module 6 (referring to figure 1 ); in order to prevent magnetic leakage, the fuselage 1 is made of YL12 hard aluminum material; the adsorption magnetic wheel 2 includes a magnetic wheel 21 and a silicon steel sheet 22, and the silicon steel sheet 22 is respectively attached to two end faces of the magnetic wheel 21 on (see Figure 4-6 ), and is fixed on the fuselage 1 by a bearing embedded in the wall of the fuselage 1; the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com