The Method of Using Cable Transmission to Realize Precise Oriented Perforation

A technology of precise orientation and cable transmission, which is applied in the direction of production fluid, earthwork drilling, wellbore/well components, etc., can solve the problems of long construction period, large resistance of wellhead rotating tubing, poor economic benefits, etc., and achieve a high success rate at the first time , Shorten well occupation time and reduce labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

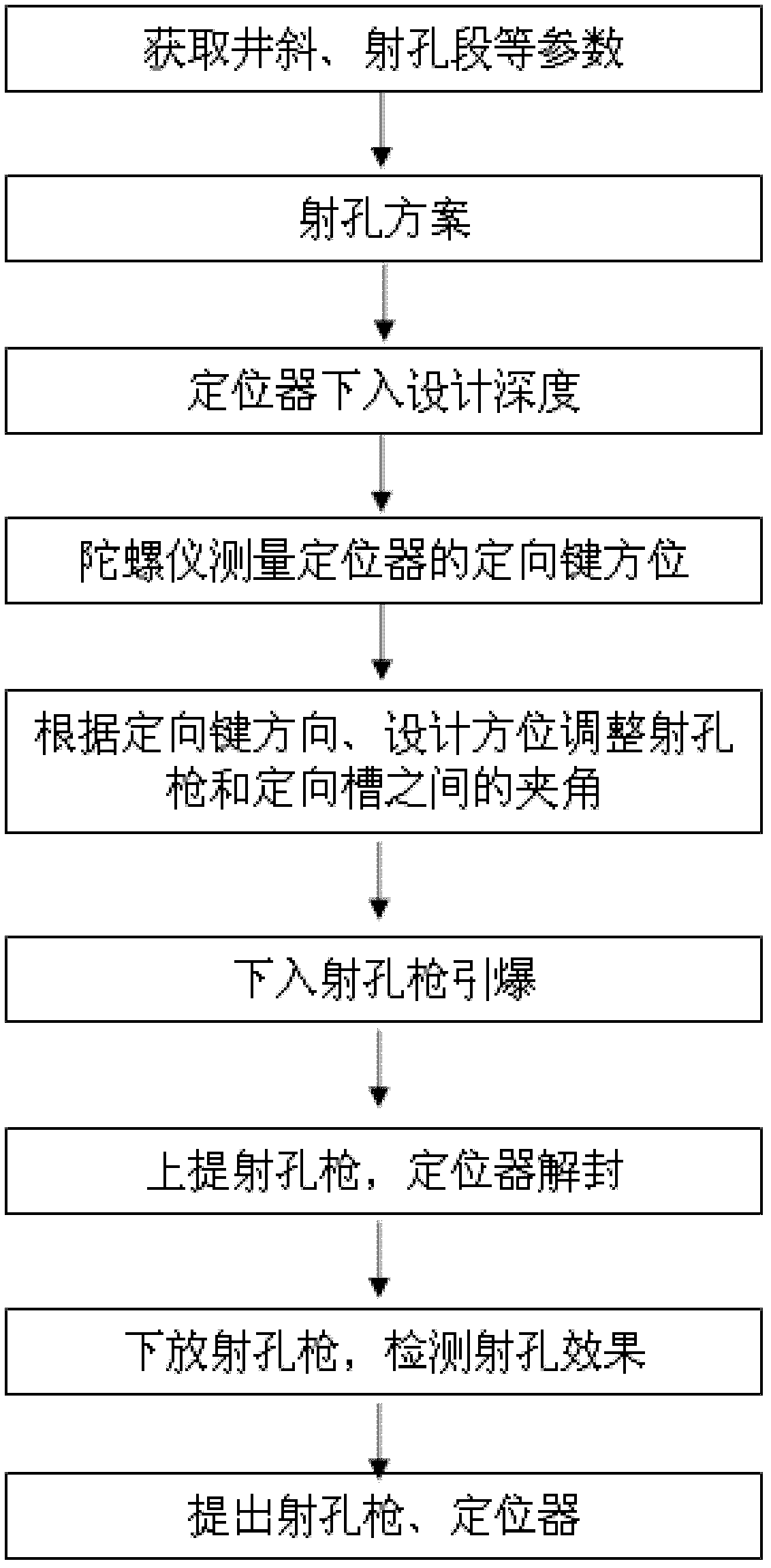

[0062] Embodiment 1: Taking the method of realizing precise directional perforation in a well using cable transmission as an example, the present invention will be further described in detail.

[0063] The directional perforation construction process of Well A in Changqing Oilfield.

[0064] 1. First, collect parameters such as well deviation and perforation section:

[0065] 2. Azimuth perforation construction design

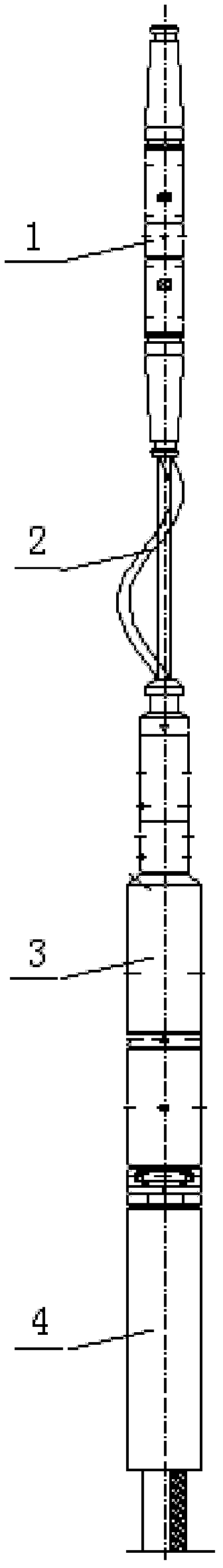

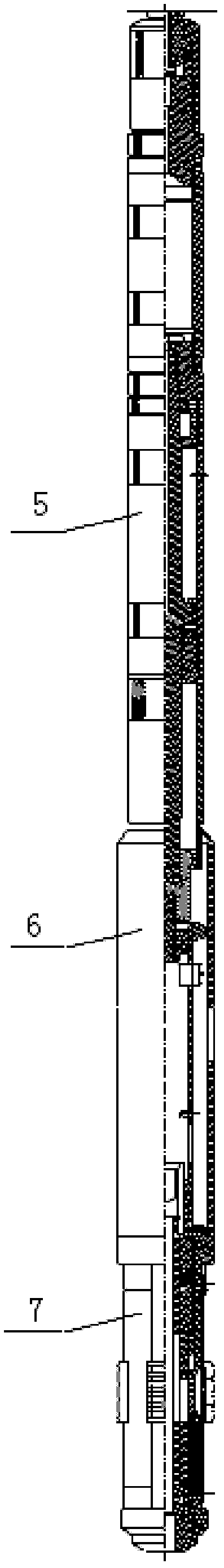

[0066] (1) Positioning support device:

[0067] It adopts 51 / 2" positioning support device, the maximum outer diameter is 114mm, the length is 1000mm, and the shearing force of the piston shear pin is 8T.

[0068] (2) Azimuth measuring instruments:

[0069] Adopt HKTL-46 gyro azimuth measuring instrument, the maximum outer diameter is 46mm, and the maximum outer diameter of the centralizing ring is 102mm.

[0070] (3) Azimuth perforating gun:

[0071] a. The outer diameter of the positioning perforator is 102mm, the maximum outer diameter of the joint is 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com