Artificial well wall sand control simulation test device and test method

A technology of artificial well wall and simulation test, which is applied in the fields of earth-moving drilling, wellbore/well components, and production fluid, etc., can solve the problem that the artificial well wall sand control simulation test function cannot be realized and is not conducive to the construction of artificial well wall sand control in oil fields. and other problems, to achieve the effect of simple structure and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

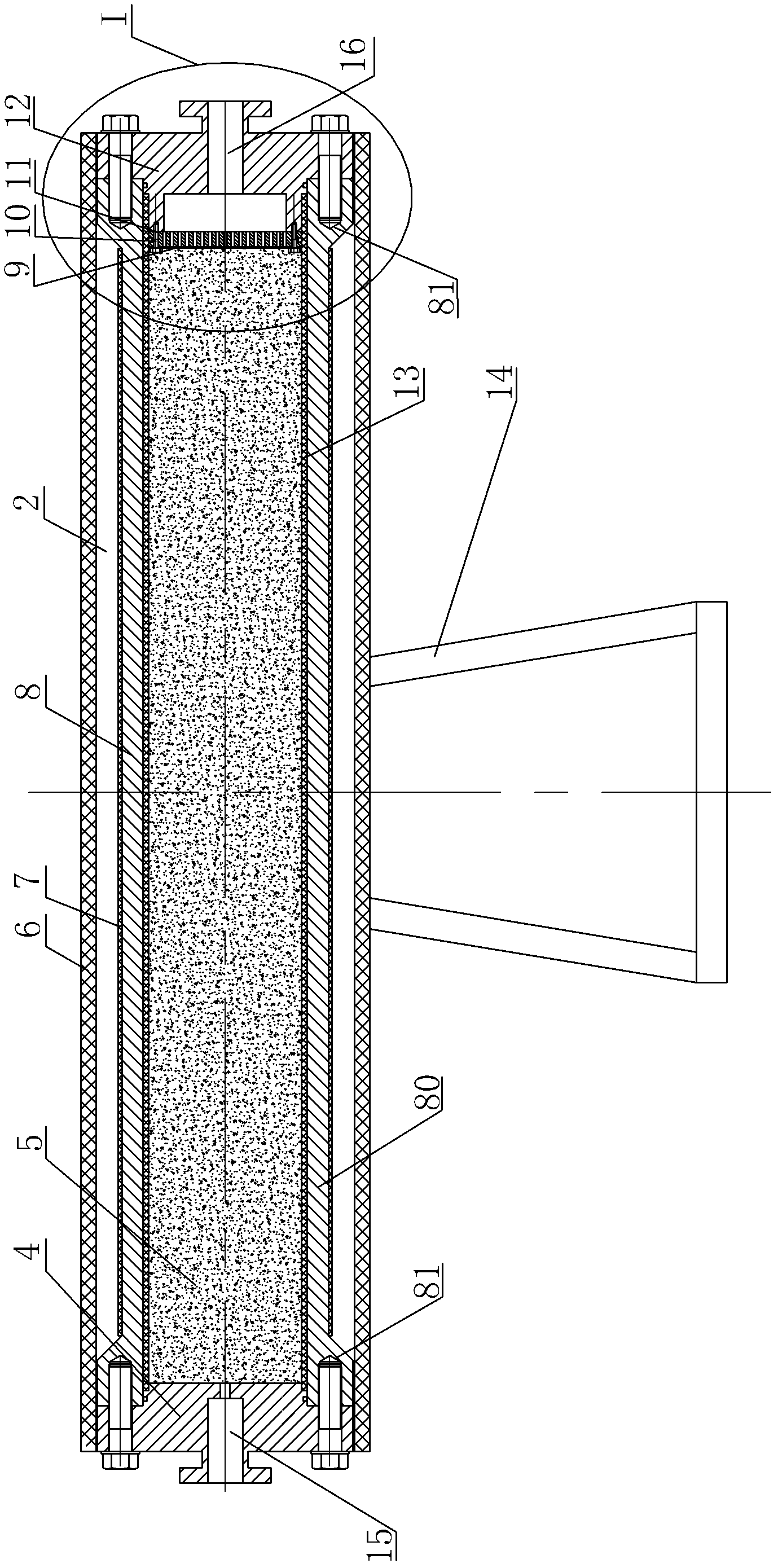

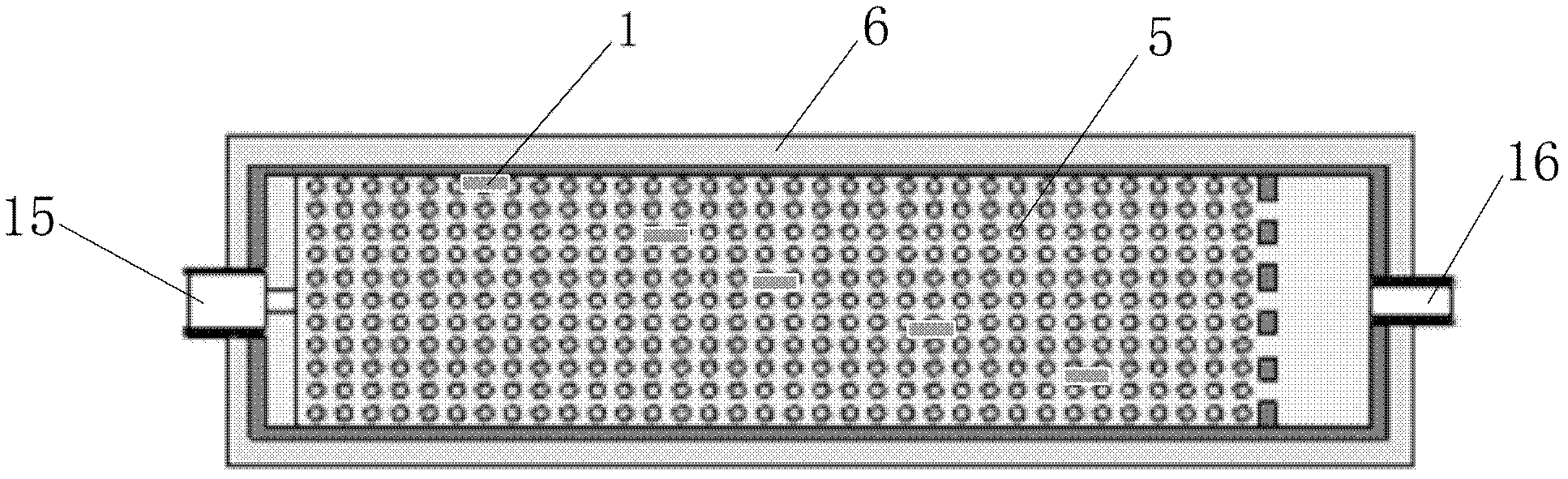

[0032] The artificial well wall sand control simulation test device proposed by the present invention at least includes: a cylinder body, which can accommodate fillers constituting the artificial well wall; two ends of the cylinder body are respectively sealed and fixed with one end cover, and one The end cover is provided with a liquid inlet, and the other end cover is provided with a liquid outlet. The artificial well wall sand control simulation test device of the present invention has simple structure and convenient operation.

[0033] Wherein, the filler may be formation sand or a sand mixing liquid containing resin sand.

[0034] Further, the outside of the cylinder is covered with a heating ring. In a specific technical solution, the heating ring can be fixed on the heating plate, and the heating ring can be fixed on the outer peripheral wall of the cylinder through the heating plate, and the three can be fixedly arranged by conventional methods. By installing a heating ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com