Nano TiO2 compounded system and application thereof in drainage and retention of waste paper deinking pulp

A technology of waste paper deinking pulp and system, which is applied in the processing of waste paper, addition of retention aids, papermaking, etc. problems, to achieve multiple flocculation opportunities, good retention and drainage effects, and the effects of being conducive to retention and drainage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

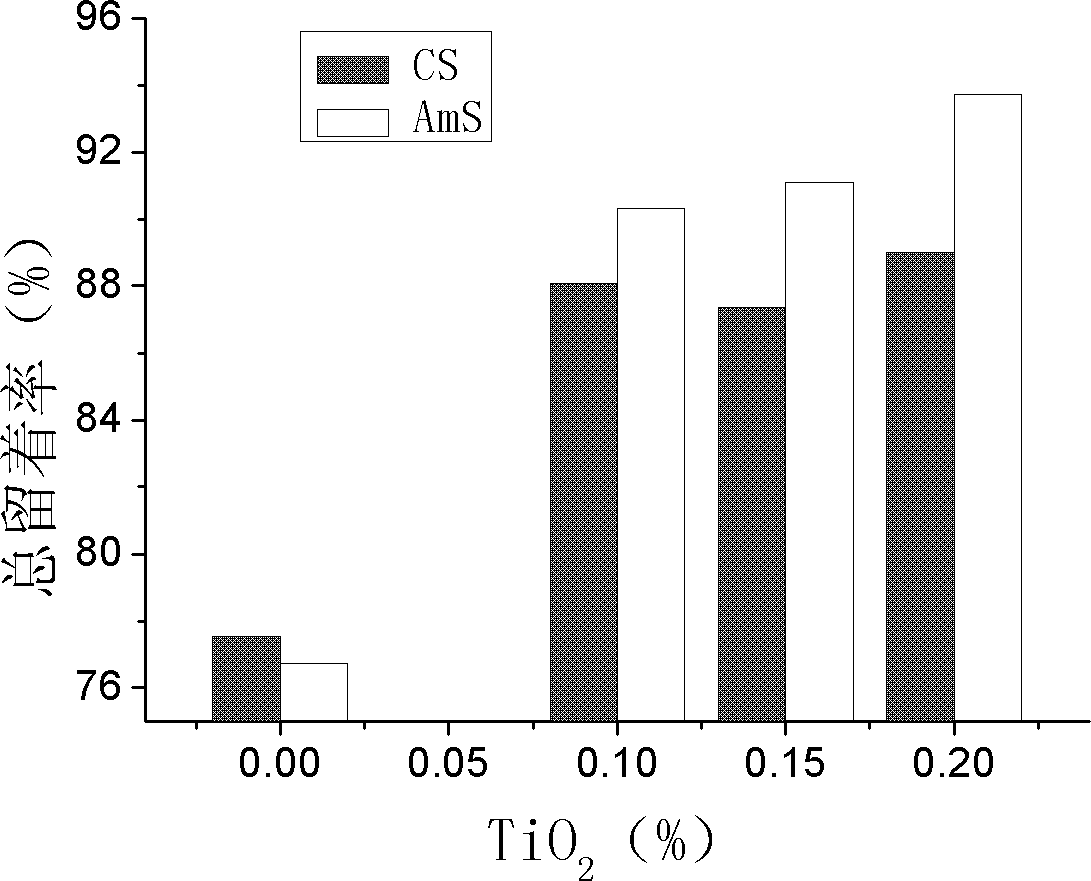

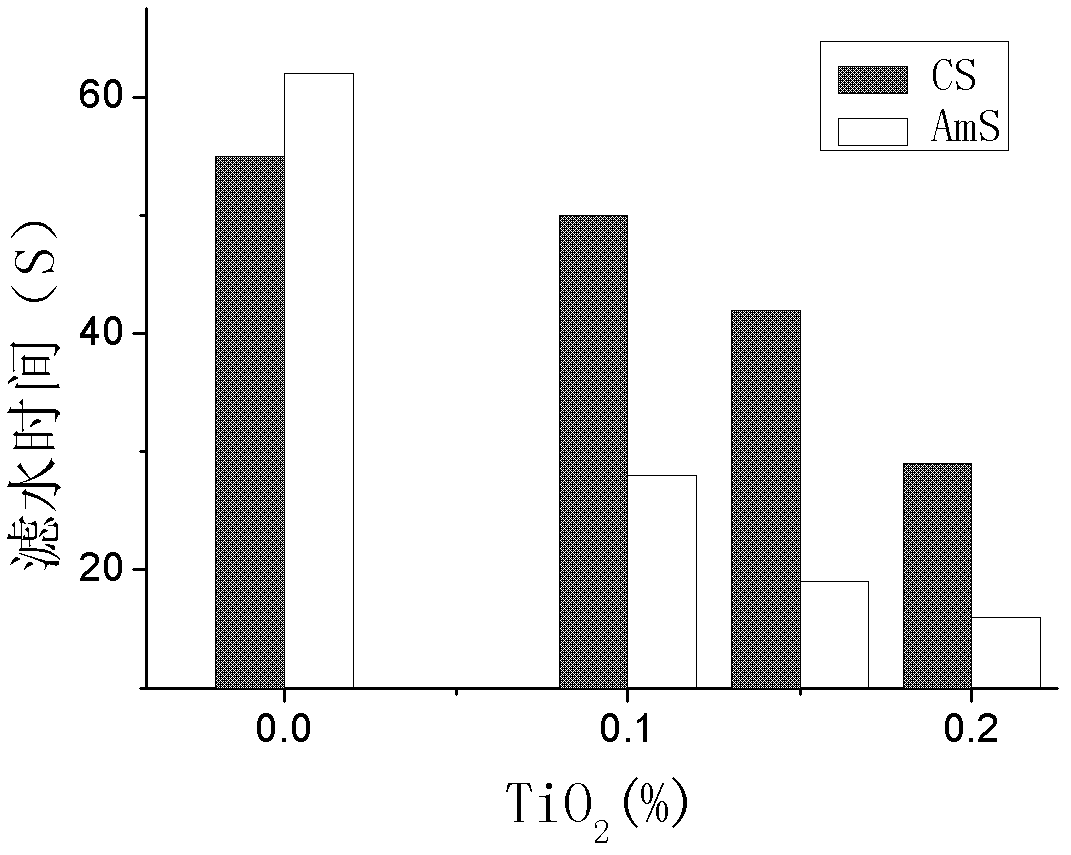

[0028] A Nano-TiO Applied to Retention and Drainage of Waste Paper Deinking Pulp 2 Binary compound system, including nano-TiO 2 And starch polymers, wherein starch polymers are amphoteric starch (AmS, its cationic substitution degree is 0.020, anionic substitution degree is 0.015) or cationic starch (CS, its cationic substitution degree is 0.035), in the binary system, nano TiO 2 See Table 1 for the addition amount of amphoteric starch or cationic starch. The filler added in the used waste paper deinking pulp is calcium carbonate, which is 20% of the absolute dry pulp of the waste paper deinking pulp.

[0029] Table 1TiO 2 -The concentration of each component in the experiment of starch binary compound system

[0030]

[0031] The steps of the dynamic water filtration experiment are as follows: for the binary system, the experimental process is as follows: take 500mL slurry and add it to the dynamic water filtration instrument, start at an initial speed of 750r / min, add ...

Embodiment 2

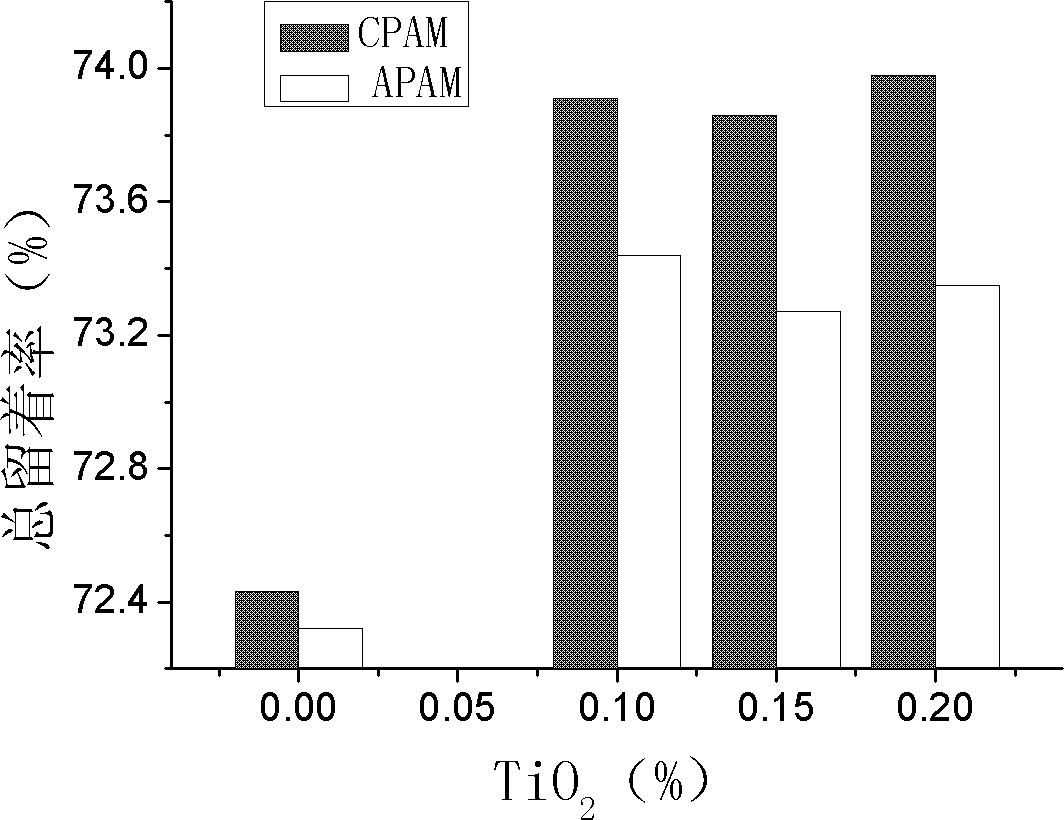

[0034] The difference between this example and Example 1 is that polyacrylamide is used as the compound, and the concentration of the compound in each system is shown in Table 2. The filler added to the waste paper deinking pulp is kaolin.

[0035] Table 2TiO 2 -Concentration of components in PAM binary compound system experiment

[0036]

[0037]Dynamic water filtration experiment: For this binary system, if the added compound is cationic polyacrylamide (CPAM, its molecular weight is 6 million, cationic degree 30%), the experimental process is as follows: Take 500mL slurry and add it to the dynamic filtration In the water meter, start with an initial speed of 750r / min, add the corresponding dose of reagent 1 (CPAM) at 30s, adjust the speed to 1200r / min at 35s, reduce the speed to 750r / min at 60s, add the corresponding dose of reagent 2 (nano TiO 2 ), keep the speed at 75s and open the valve of the dynamic water filter to collect the filtrate; if the added compound is an...

Embodiment 3

[0040] The difference between this embodiment and embodiment 1 is: this embodiment uses nano-TiO 2 Based on the ternary compound system, nano-TiO 2 It is compounded with polyacrylamide and starch as a retention and drainage system, and the concentration of the compound in each formula is shown in Table 3. The filler added in the waste paper deinking pulp is talcum powder.

[0041] Table 3 Ternary system experimental formula

[0042]

[0043] Dynamic water filtration experiment: For the ternary system, add reagent 1 (CPAM / APAM: CPAM, its molecular weight is 6 million, cationic degree 30%; APAM, its molecular weight is 6 million) at 30S, add reagent 2 (CS / AmS: AmS, its cationic substitution degree is 0.020, and its anionic substitution degree is 0.015; CS, its cationic substitution degree is 0.035), and reagent 3 (nano-TiO 2 ), accept the filtrate at 110S, and other operations are the same as the binary system.

[0044] from Figure 5 Image 6 We found that formula 3 h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of substitution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com