A kind of rubber mixing system and rubber mixing process

A technology of rubber mixing and rubber, applied in the field of rubber mixing system and rubber mixing process, can solve problems such as affecting the quality of rubber products, waste of equipment investment, increasing the number of equipment, etc., to avoid dust flying and loss, avoid pollution, reduce The effect of the number of devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

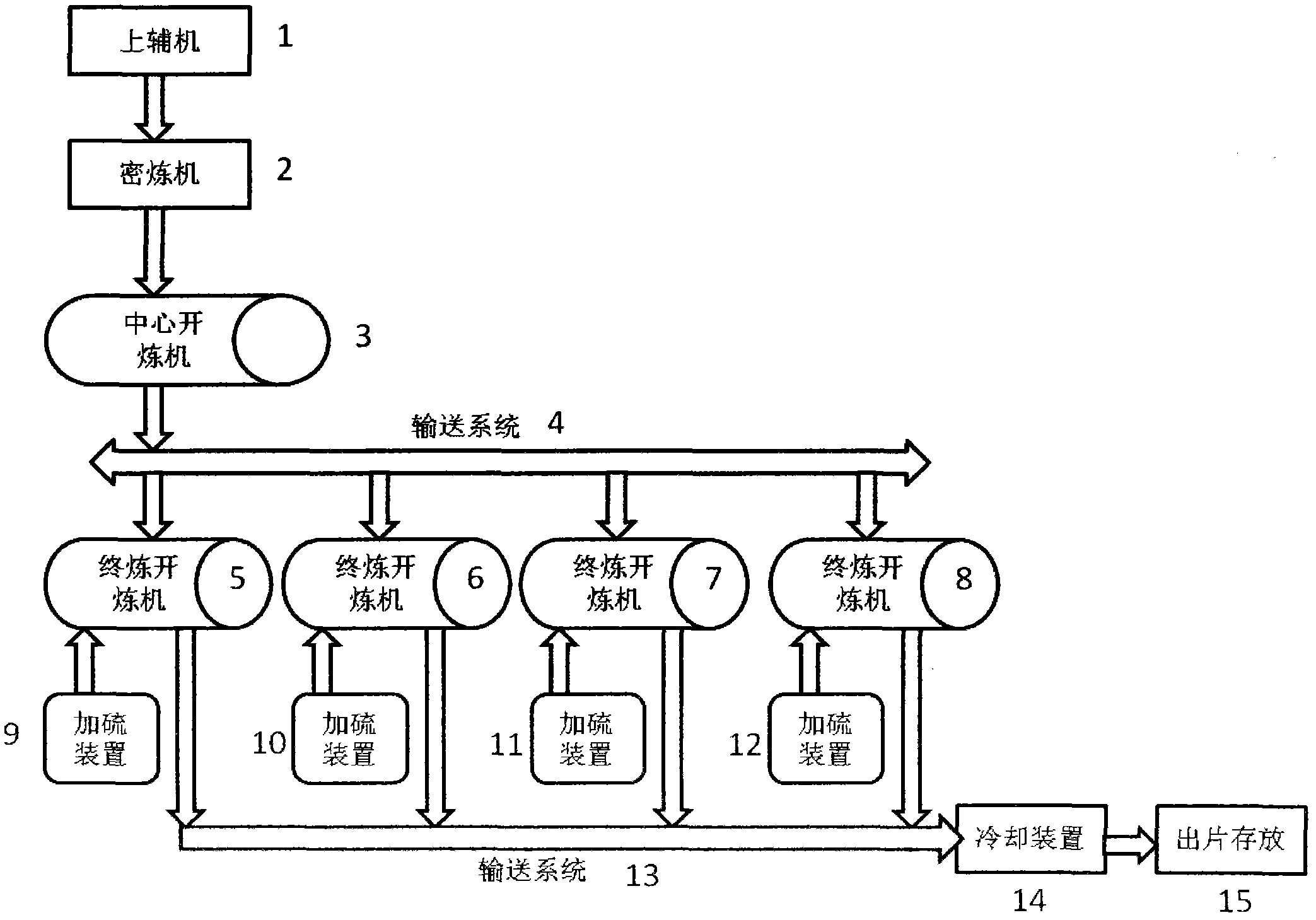

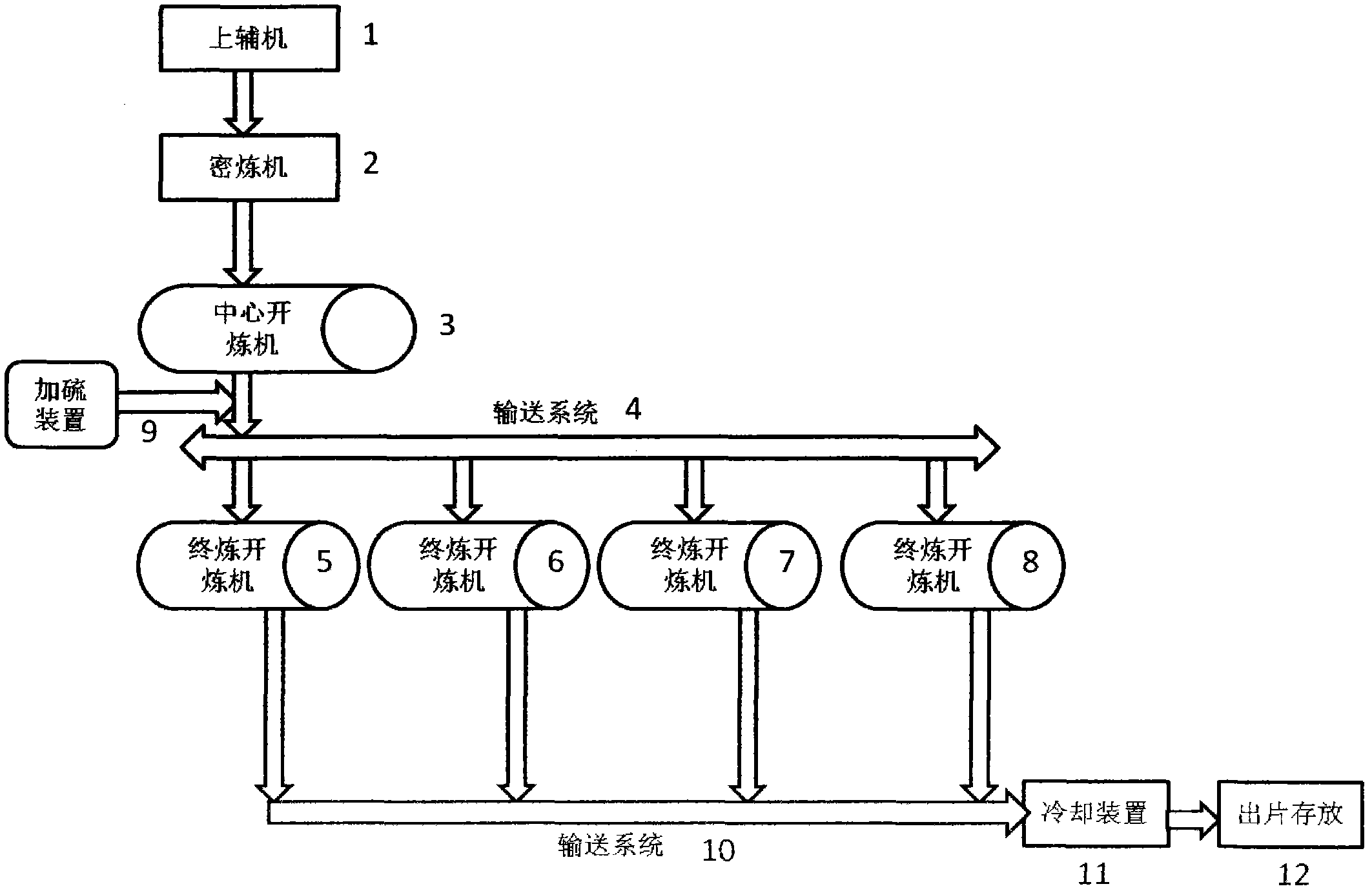

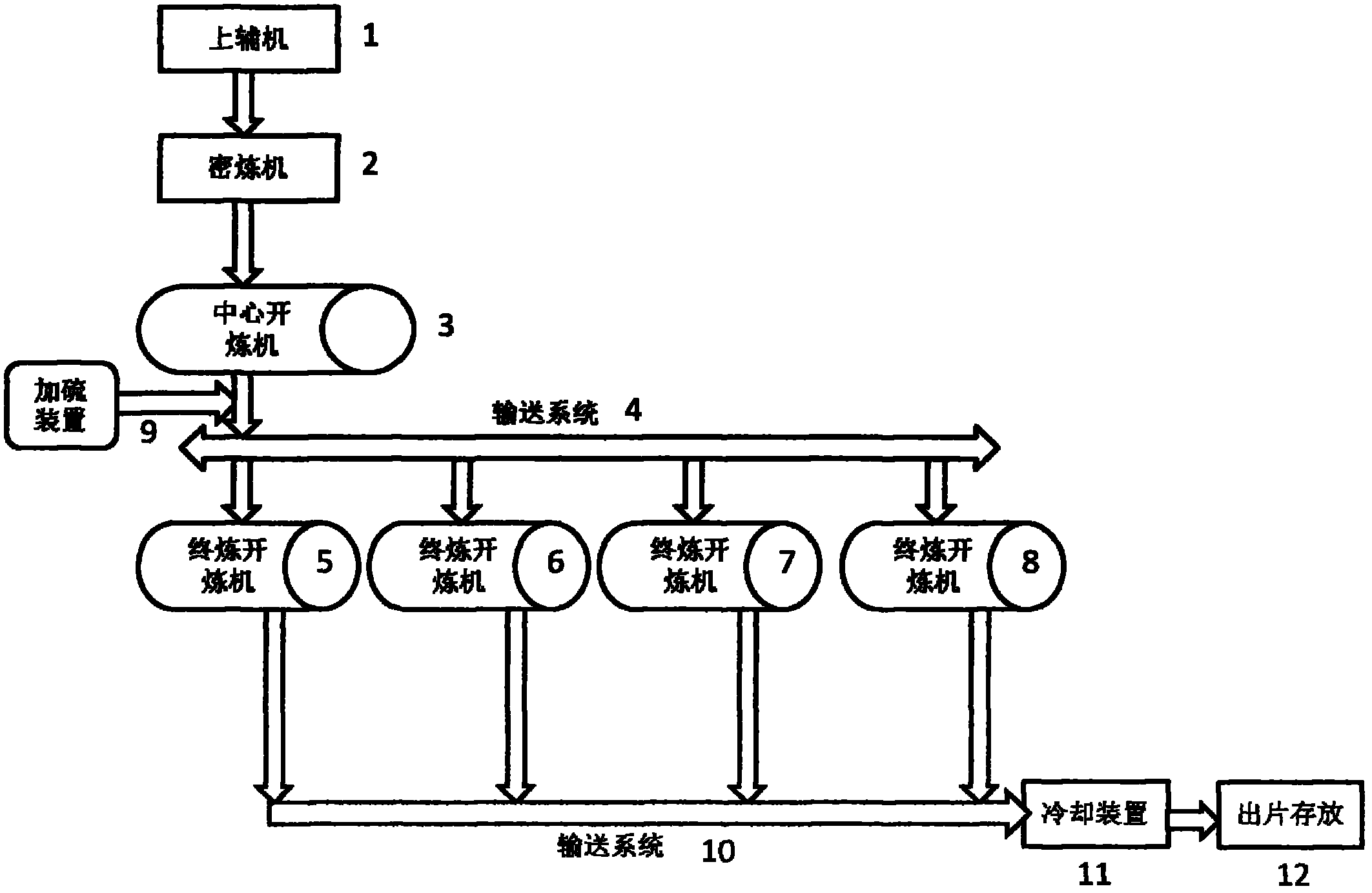

[0021] Refer to the attached figure 2 , the present invention will be further described in conjunction with specific embodiments.

[0022] The rubber mixing process of the present invention comprises:

[0023] Put the rubber and the carbon black additive transferred from the upper auxiliary machine 1 into the internal mixer 2 for banburying, and the banburying time is 2-3 minutes;

[0024] The internal mixer 2 discharges the rubber material to the central open mixer 3;

[0025] The central mill 3 uses two rollers to quickly cool and supplement the discharged rubber material. After 2-3 minutes of cooling and mixing, the temperature of the rubber material drops by 40-50 degrees;

[0026] Deglue the rubber material to the central conveyor belt in the form of film;

[0027] While the central mill 3 is conveying the belt to the center to remove the rubber, the vulcanization aid masterbatch that has been weighed is transported to the discharged film through the vulcanization dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com