The Processing Method of Improving the Center Deviation Precision of Aspheric Lens

An aspherical lens, aspherical technology, applied in the direction of lenses, metal processing equipment, manufacturing tools, etc., can solve problems such as damage to center deviation, inaccurate positioning, center deviation correction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

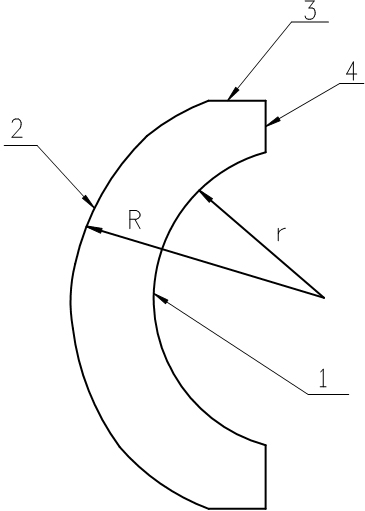

[0029] Embodiment 1: The present embodiment 1 takes processing germanium aspheric lens---imaging lens as example: the technological requirement of this imaging lens is

[0030] The outer circle size of the blank is φ25, and the finished outer circle size of the lens is φ24 ;

[0031] Radius of spherical curvature R-10.447, platform size φ16, surface accuracy N=3, ΔN=0.3;

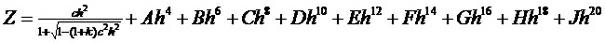

[0032] Aspheric equation

[0033]

[0034] Among them, c=1 / 14.028, h 2 = x 2 + y 2 , K=0, A=-1.0515E-06, B=-1.313E-8, C=1.0551E-10,

[0035] D=-9.0347E-13, E=0, F=0, G=0, H=-0, J=0,

[0036] Surface accuracy Rt≤0.4μm, Ra≤0.04μm;

[0037] Center deviation χ≤1.2';

[0038] Center thickness dimension 5±0.02;

[0039] Surface blemish grade B=Ⅴ.

[0040] The processing method of the imaging lens is as follows:

[0041] (1) Calculate the radius of the best fitting sphere of the aspheric surface, and the radius of the best fitting sphere of the aspher...

Embodiment 2

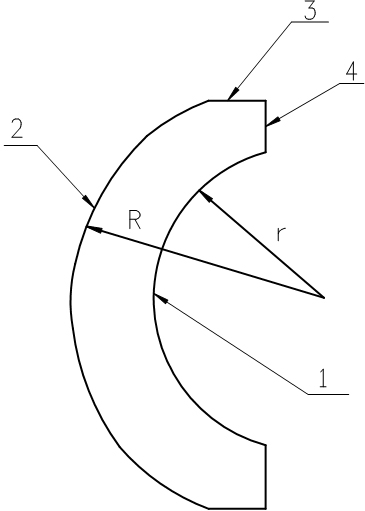

[0051] Embodiment 2: This embodiment 2 takes the processing of germanium aspheric lens—narrow field of view eyepiece as an example:

[0052] The process requirements of the narrow field of view eyepiece are: the outer circle size of the blank is φ25.5; the finished outer circle size of the lens is φ23.5 ; Spherical curvature radius R-237.7, platform size φ21, surface shape accuracy N=3, ΔN=0.3;

[0053] Aspheric equation

[0054]

[0055] Where: c=1 / -105.3971, h 2 = x 2 + y 2 , K=70.913844, A=0.108734E-04, B=0.453598E-08,

[0056] C=0.771109E-10, D=0.191692E-11, E=-0.118487E-18, F=0, G=0, H=0, J=0,

[0057] Surface accuracy Rt≤0.4μm, Ra≤0.04μm;

[0058] Center deviation χ≤0.3′; center thickness dimension 3.4±0.03; surface defect grade B=Ⅴ.

[0059] The processing method of the narrow field eyepiece is as follows:

[0060] (1) Calculate the best fitting spherical radius of the aspheric surface, and the best fitting spherical radius of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com