Novel paraffin injection valve of paraffin continuous molding machine

A molding machine and wax injection technology, which is applied to valve details, multi-way valves, valve devices, etc., can solve the problems of waste of raw materials, many processes, and large space occupation, so as to ensure the accuracy of wax injection, avoid jet splashing, and slow down the flow rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

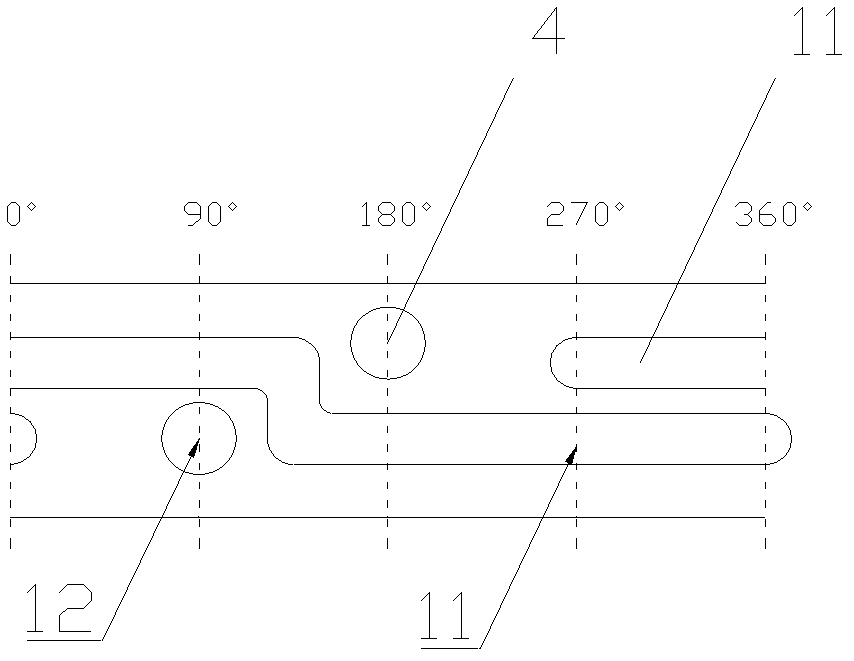

[0019] Such as figure 1 As shown, the wax injection valve is composed of a cylinder 1, a valve stem 2, a valve body 3, a valve core 5 and a valve seat 7. The cylinder 1 is connected to the upper end of the valve stem 2, and the valve stem 2 is a rod-shaped body processed by 304 stainless steel. , the lower end of the valve stem 2 is in the lower part of the valve body 3, the end is inlaid with a valve core 5, and the middle part of the valve core 5 is provided with an opening groove 6, mainly to reduce the weight of the valve core 5; through the up and down movement of the valve core 5, the valve The inlet 12 of the body 3 is either communicated with the outlet 8 or communicated with the return port 4; the lower end of the valve body 3 is processed to form a valve seat 7.

[0020] The valve body 3 is a cylindrical three-way valve body of φ100mm×100mm processed by ordinary 304 stainless steel. The side surface corresponding to the upper part of the valve body 3 forms an angle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com