Scale-like combination blade

A sub-combination, blade technology, applied in wind power generation, wind turbines, machines/engines, etc., can solve the problems of wasting space wind energy resources, increasing tower height, low production capacity of single blade, etc. The effect of blade length, manufacturing cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

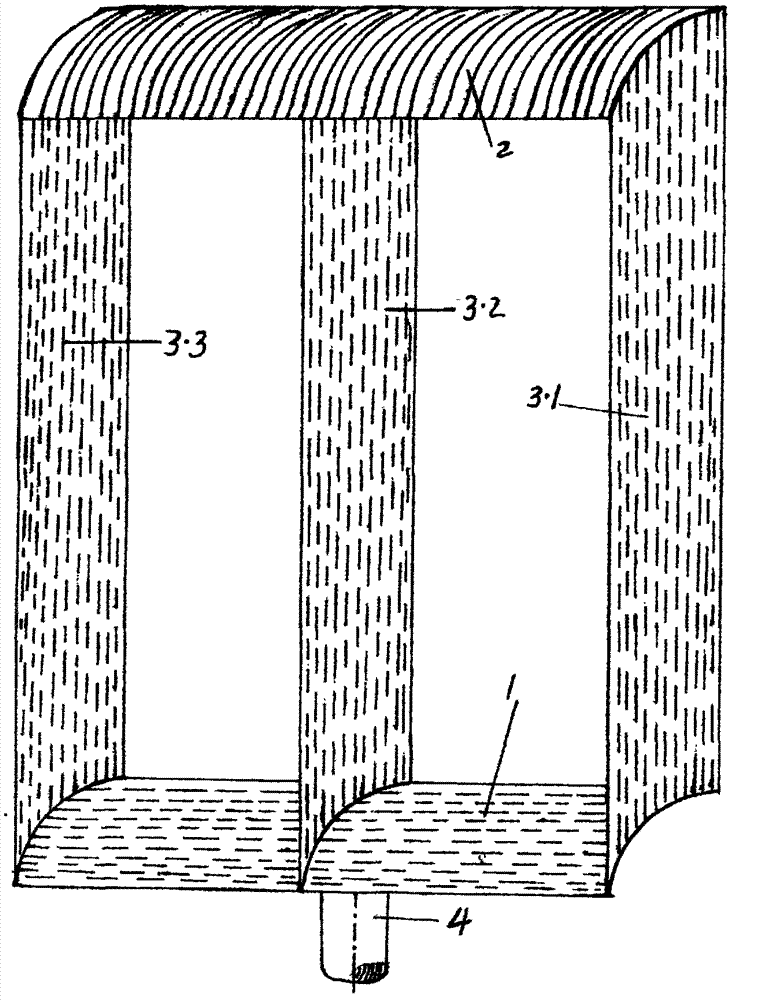

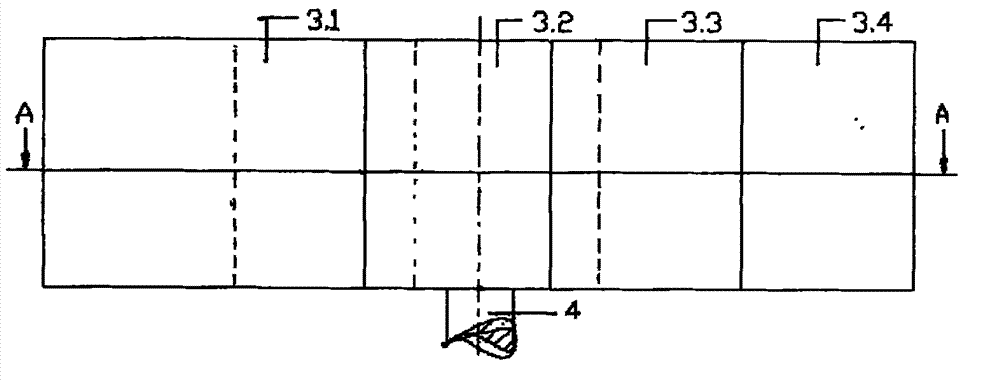

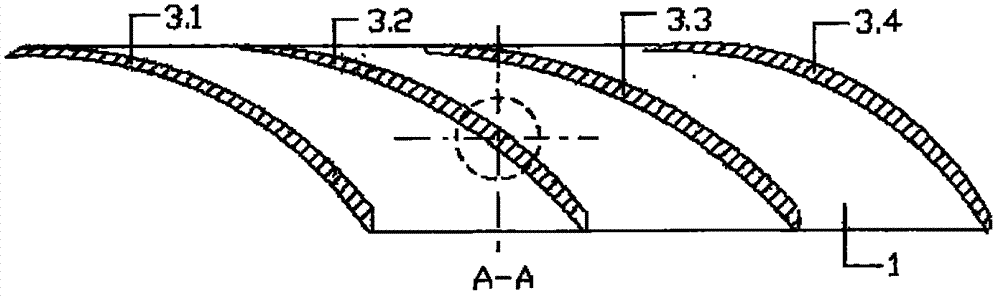

[0018] Depend on Figure 1-Figure 6 As shown, the scale combination blade of the present technology invention is mainly composed of blade combinations of one level or more than two levels. The combination of blades at each level is composed of at least two or more than two single blades. A group of blade combinations of the scale combination blades must be assembled with at least two or more single blades. In the combination of blades at each level, according to the number of single blades and the size of the length and width of single blades, more than two single blades are vertically arranged and fixed on the bottom plate 1 according to the distance required by the specific design. The arrangement of each single blade in the leaf combination is to start from the first single blade 3.1 in the front according to the scale shape, and then arrange it in the order of the second single blade 3.2, the third single blade 3.3, etc., until Arrange the number of single leaves that ne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com