Zero-clearance rear-mounted mold slip form paver

A slip-form paver and zero-gap technology, applied in roads, road repairs, roads, etc., can solve problems such as restricting the application prospects of slip-form construction technology, affecting the reliability of oil cylinders, and not having construction conditions, etc., achieving compact structure, The effect of stable center of gravity structure and reasonable length design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

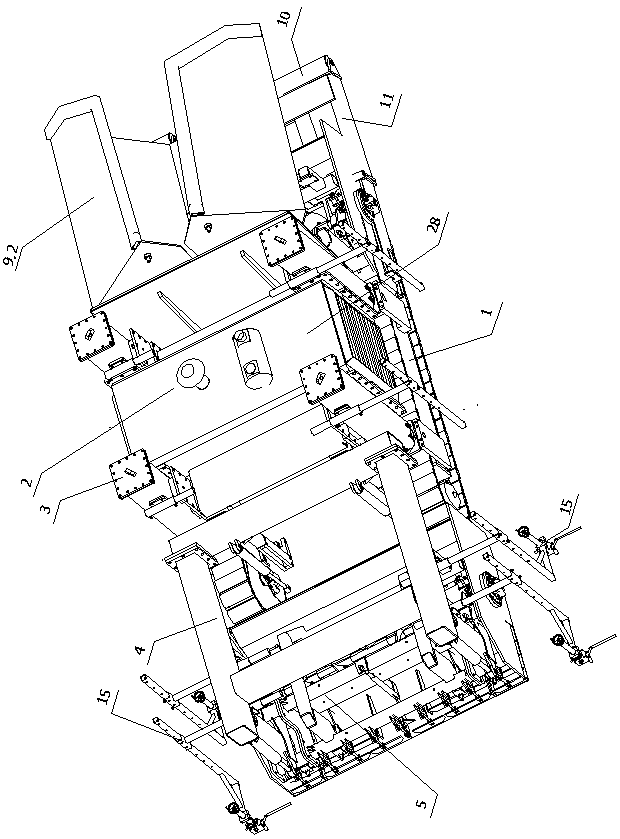

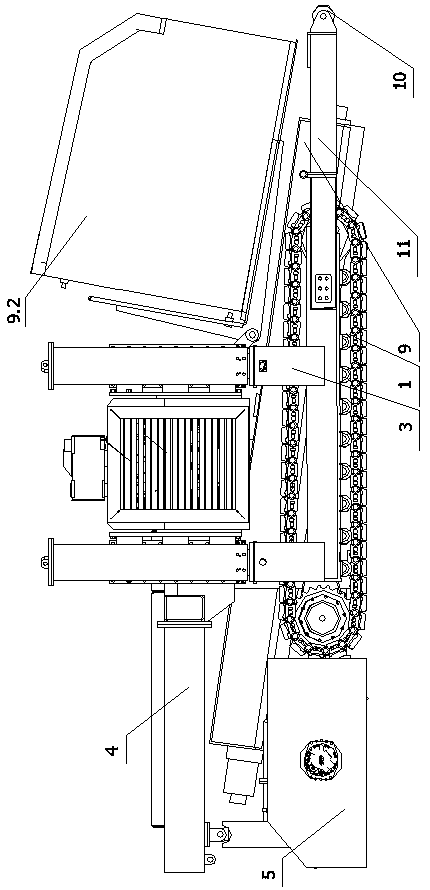

[0036] Such as Figure 1-7 As shown, the present invention includes a main engine 2 and a rear mold paving device 5. The main engine 2 includes a crawler walking device 1, a lifting column device 3 and an engine assembly 28. The rear side of the lifting column device 3 is connected with a square frame platform 4. Put mold paving device 5 and be arranged on the below of square frame platform 4.

[0037] As a further description of this embodiment, the width of the crawler traveling device 1 is smaller than that of the rear mold paving device 5, so that the present invention can adapt to the construction of a road surface as wide as the roadbed.

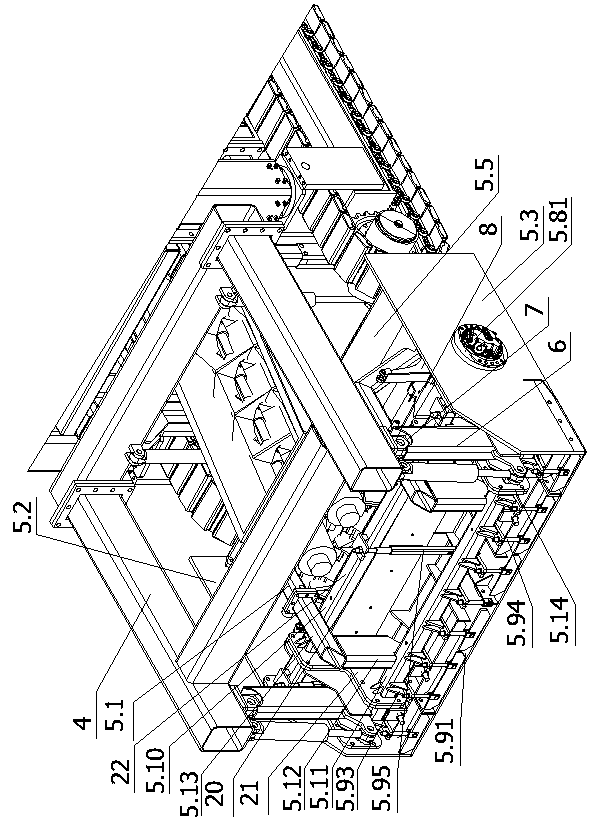

[0038] The rear mold paving device 5 includes a mold frame 5.1, and the mold frame 5.1 includes a left side plate 5.2 and a right side plate 5.3, and a front baffle plate 5.5 and a middle part arranged in front and rear are arranged between the left side plate 5.2 and the right side plate 5.3. The baffle frame 20, the middle baffle fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com