A method and device for preparing a micro-dot anti-counterfeiting imprint

A preparation device and micro-dot technology, applied in printing devices, printing, etc., can solve problems affecting processing quality, precipitation, and glue quality, and achieve the effect of ensuring uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

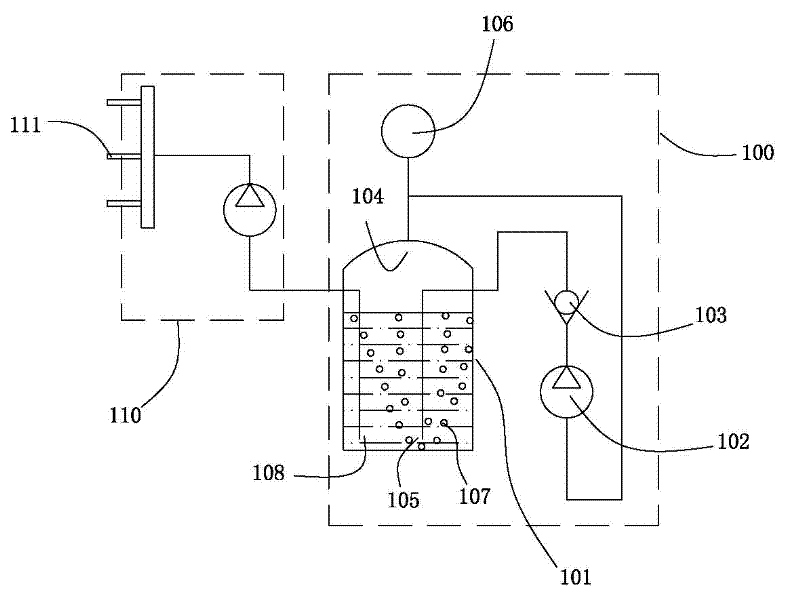

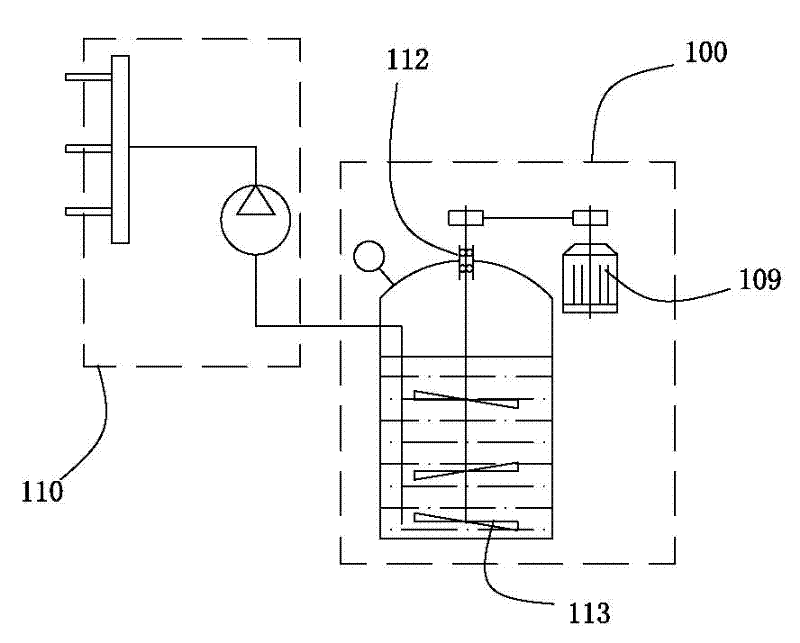

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings.

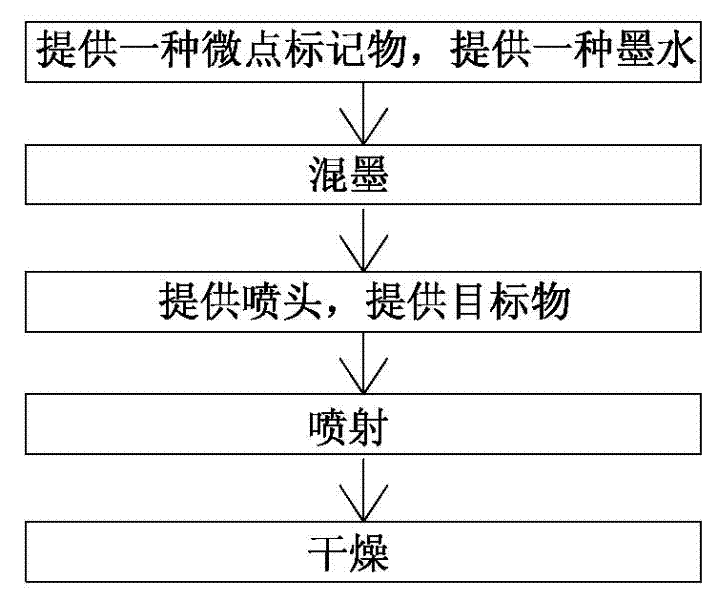

[0027] refer to figure 1 , the first embodiment of the present invention is a method for preparing a micro-dot anti-counterfeiting imprint, which is characterized in that it comprises the following steps:

[0028] S1, providing a micro-dot marker and an ink;

[0029] S2, ink mixing, that is to mix the micro-dot markers and ink evenly;

[0030] S3, providing at least two nozzles to provide the target;

[0031] S4, spraying, spraying the ink mixed with micro-dot markers to the target through the nozzle;

[0032] S5, drying the ink mixed with micro-dot markers;

[0033] During the jetting process, the ink mixing step is carried out continuously, and the ink mixing, ink supply to the nozzle, and jetting are completed in a fully enclosed liquid path.

[0034] As a further optimization of this embodiment, this embodiment can also be defined as follows: there a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com