Composite Ribbon Laying Apparatus and Method Using Laser

A composite material and laying device technology, applied in the field of laser technology application, can solve the problems of affecting processing flexibility, reducing production efficiency, complex manufacturing process, etc., and achieve the effect of improving the laying process efficiency, simplifying the manufacturing process, and simplifying the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the drawings.

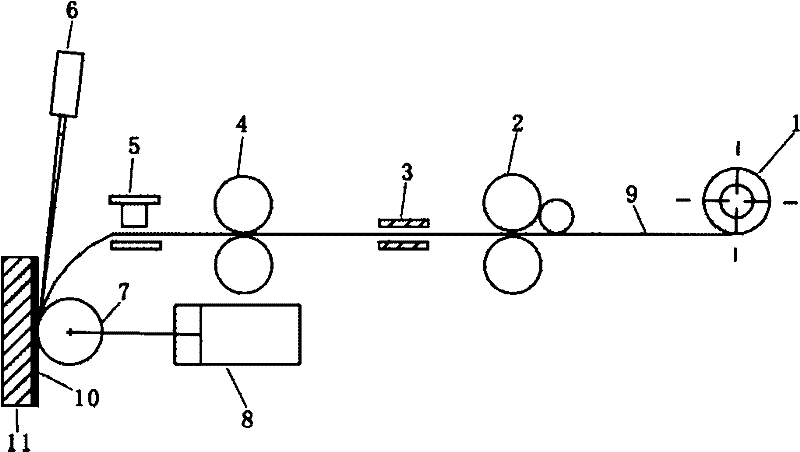

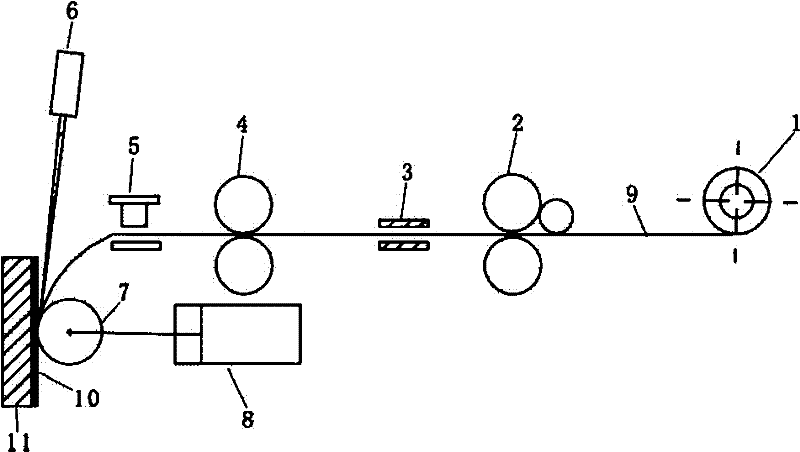

[0028] figure 1 It is a schematic diagram showing the overall structure of the composite material ribbon laying device using laser according to the present invention. As shown in this figure, the composite material ribbon laying device utilizing laser includes: as the unwinding reel 1 of the wire feeding part, the composite material ribbon is wound, and the composite material ribbon can be sent out while rotating. Here, the composite material ribbon is for example It can be a wet fiber bundle with a certain resin content; the gluing roller 2 as the gluing part, gluing the surface of the composite material ribbon sent out from the above-mentioned unwinding reel 1; the traction and clamping mechanism 3 and the guide roller as the guiding part 4. Guide and clamp the composite material ribbon after gluing, so as to stretch and convey the composite mater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com