An automatic assembly table for the outer ball joint assembly of automobile tie rods

A technology of automatic assembly and automobile tie rods, which is applied in the direction of assembly machines, metal processing equipment, manufacturing tools, etc., can solve the problems of low efficiency, high waste rate of outer ball joint products, and affecting the driving safety of enterprises, and achieve novel design and work efficiency. Stable and reliable, protected from damage effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

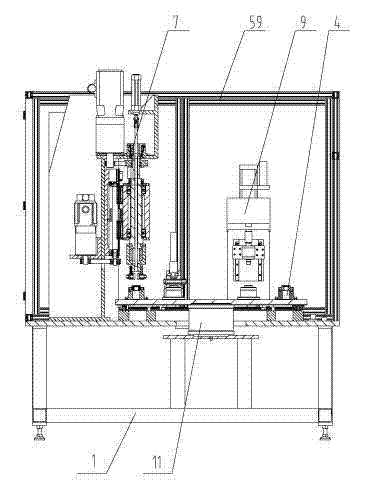

[0030] The automatic assembly table for the outer ball joint assembly of the automobile tie rod is composed of a frame 1, an indexing plate 2, an electric control cabinet 3, an accompanying fixture 4, a ball pin pressing device 5, a cover material detection device 6, and a cover plate The screw riveting and pressing device 7, the ball pin swinging torque detection device 8 and the dust cover pressing device 9 are composed, the frame 1 is provided with a protective cover 59, and the frame 1 table in the protective cover 59 passes through the ring guide rail 10 and the straight The vomiting motor 11 is equipped with an indexing plate 2, and six accompanying fixtures 4 are uniformly distributed on the surface of the indexing plate 2. The accompanying fixture 4 is composed of a base 12, a workpiece support 13 and a workpiece baffle plate 14. The workpiece support 13 passes through the bolt Fixedly installed on the base 12, the workpiece baffle 14 is fixedly installed on the upper s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com