Start-up method of finishing mill for hot-rolled wide-band steel

A technology of finishing rolling mill and wide steel, applied in the field of starting of finishing rolling mill

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] After the finishing mill for hot-rolling wide strips has all the conditions required for start-up, proceed as follows:

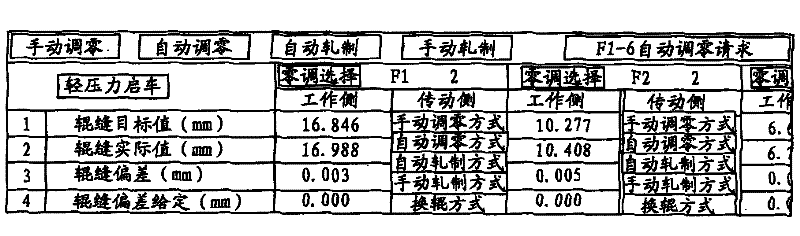

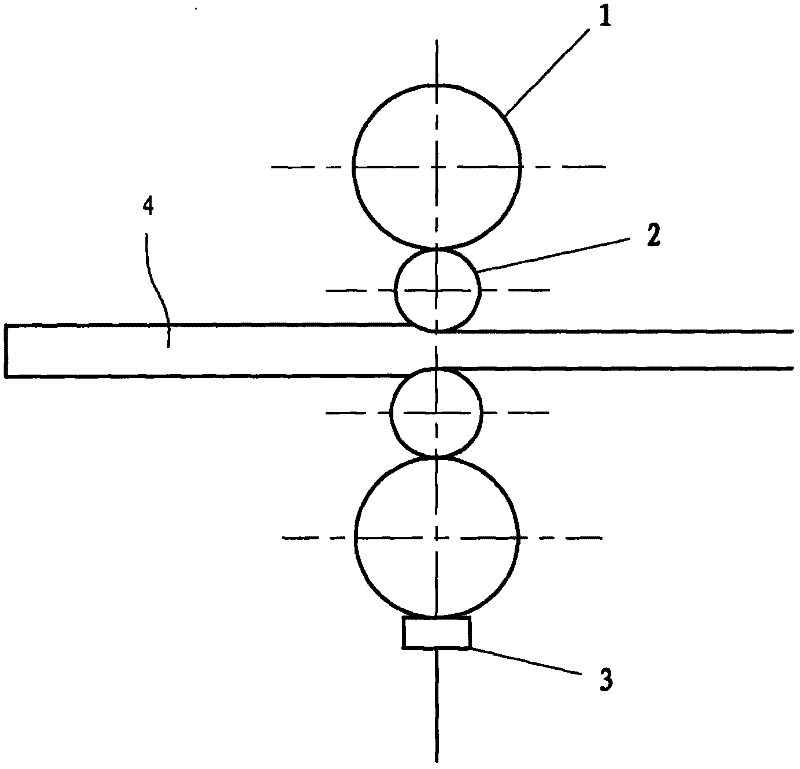

[0024] 1) Click the "light pressure start" dialog box on the zero-adjustment start screen (such as figure 2 shown in ), so that the AGC cylinders of each stand of the finishing rolling mill will automatically perform static pressing, and when the pressure detected by the piezo-magnetic indenter reaches 200T, the AGC cylinders will automatically stop pressing (automatically controlled by the program);

[0025] 2) Click the "F1-6 Automatic Zero Adjustment Request" dialog box on the zero adjustment start screen (such as figure 2 shown in), select zero speed start. Here, "F1-6 Automatic Zero Adjustment Request" is a confirmation of the selection of automatic zero adjustment speed. Click this dialog box once, and the dialog box will change color (for example, turn green), and the automatic zero adjustment speed selection will be input; click again In t...

Embodiment 2

[0028] After the finishing mill for hot-rolling wide strips has all the conditions required for start-up, proceed as follows:

[0029] 1) Click the "light pressure start" button on the zero-adjustment start screen (such as figure 2 shown in ), so that the AGC cylinders of each stand of the finishing rolling mill will automatically perform static pressing, and when the pressure detected by the magnetometer reaches 200T or more, the AGC cylinders will automatically stop pressing;

[0030] 2) In the semi-automatic screen, manually set the speed;

[0031] 3) Control the main drive of the rolling mill at 2m / s 2 The acceleration automatically starts and rises to the manually set speed (F1-F6 zero-adjustment speed: 104, 150, 197, 245, 301, 354, unit: m / min), thus completing the start-up function.

[0032] Therefore, compared with the method according to the prior art of starting the finishing train of hot-rolled wide strips in no-load mode, the advantages of the present invention ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com