Roller parameter setting method for flatness and surface quality control of levelling unit

A technology of parameter setting and surface quality, applied in the direction of contour control, etc., can solve problems affecting the quality of finished products, wave shape and surface defects, weakening the effect of plate shape and surface quality control, etc., to bring economic benefits and reduce the probability of occurrence , Reduce the effect of color difference defects on the surface of strip steel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

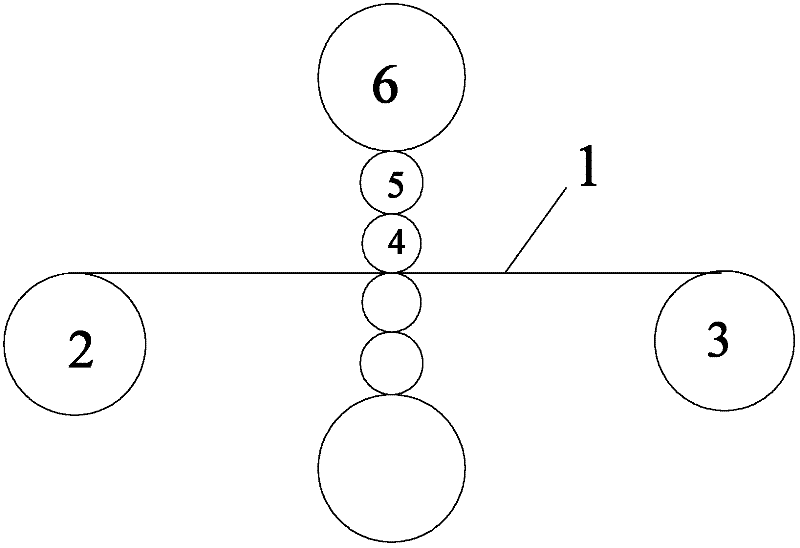

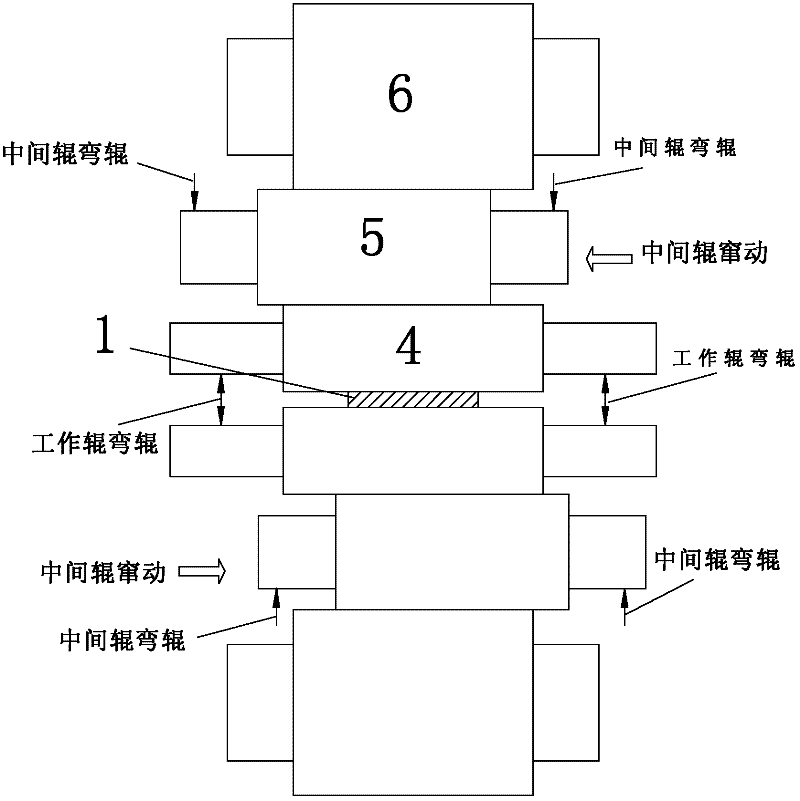

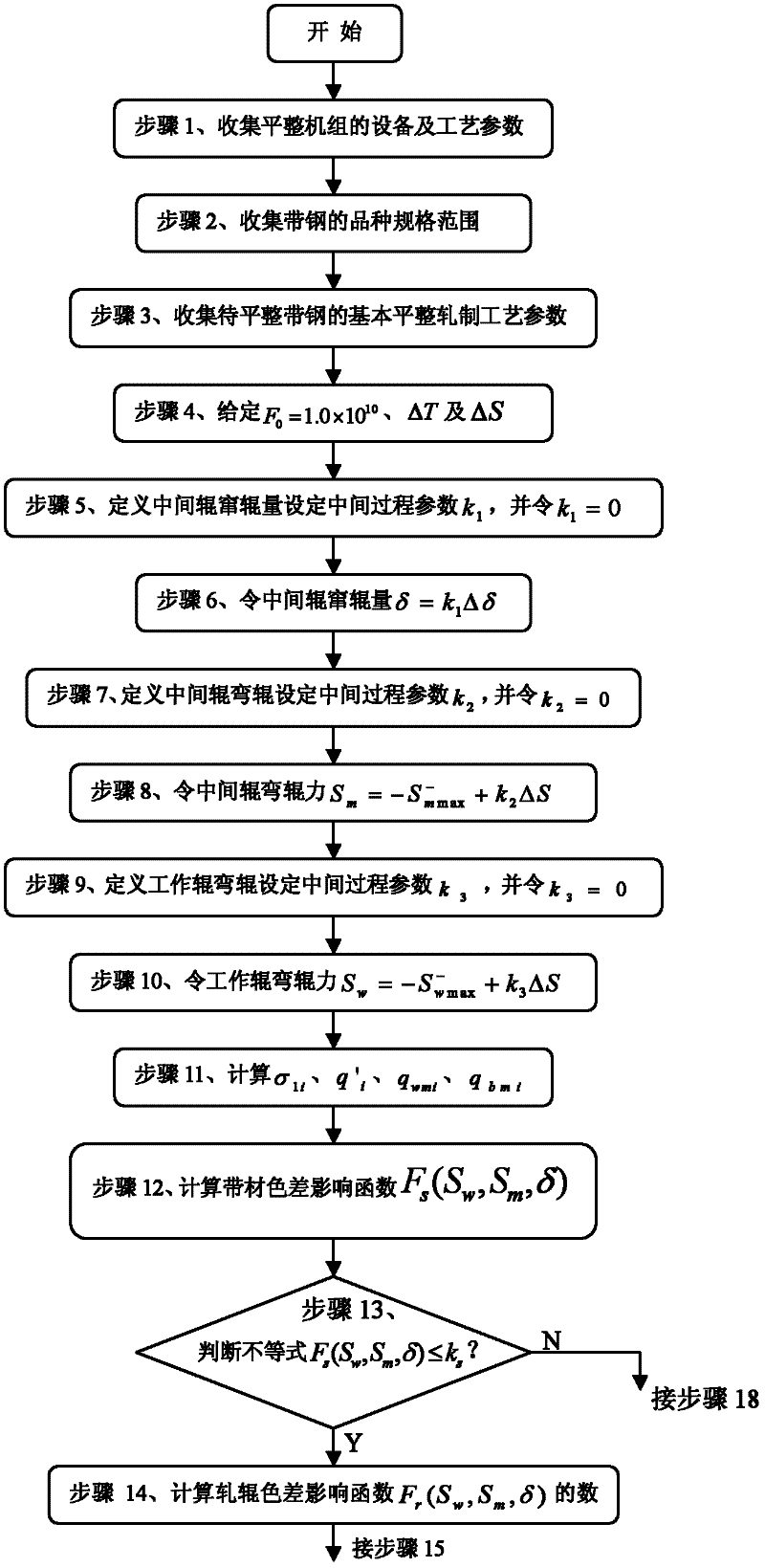

[0034] In order to illustrate the basic idea of the present invention, a certain 1850CVC-6 type smoothing unit is taken as an example, with the help of figure 1 To describe the comprehensive optimization and setting process of the roll system parameters on a specific skin pass unit for a steel strip with a specification of 1200mm*0.8mm and a steel grade of SPCC:

[0035] First, in step 1, collect the equipment and process parameters of the skin pass unit, including the work roll body length L W =1850mm, working roll diameter DW =360mm, middle roll body length L M =1850mm, intermediate roll diameter D M =400mm, back-up roll body length L b =1850mm, back-up roller diameter D b =900mm, the distance between the drive side of the back-up roller and the center of the screw on the working side is l 1 =2500mm, the center distance between the drive side of the work roll and the bending roll hydraulic cylinder on the work side l 2 =2500mm, the maximum positive roll bending force ...

Embodiment 2

[0059] In order to further illustrate the basic idea of the present invention, a 1850CVC-6 type smoothing unit is now taken as an example, with the help of figure 1 To describe the comprehensive optimization and setting process of the roll system parameters on a specific skin pass unit for a steel strip with a specification of 1000mm*0.6mm and a steel type of DC06:

[0060] First, in step 1, collect the equipment and process parameters of the skin pass unit, including the work roll body length L W =1850mm, working roll diameter D W =360mm, middle roll body length L M =1850mm, intermediate roll diameter D M =420mm, back-up roll body length L b =1850mm, back-up roller diameter D b =900mm, the distance between the drive side of the back-up roller and the center of the screw on the working side is l 1 =2500mm, the center distance between the drive side of the work roll and the bending roll hydraulic cylinder on the work side l 2 =2500mm, the maximum positive roll bending f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com