cutting stapler

A suturing device and matching technology, applied in the field of medical devices, can solve problems such as difficulty in firing, inability to push, increase friction between the firing piece and the right side wall of the sliding groove, etc., and achieve the effect of easy firing and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

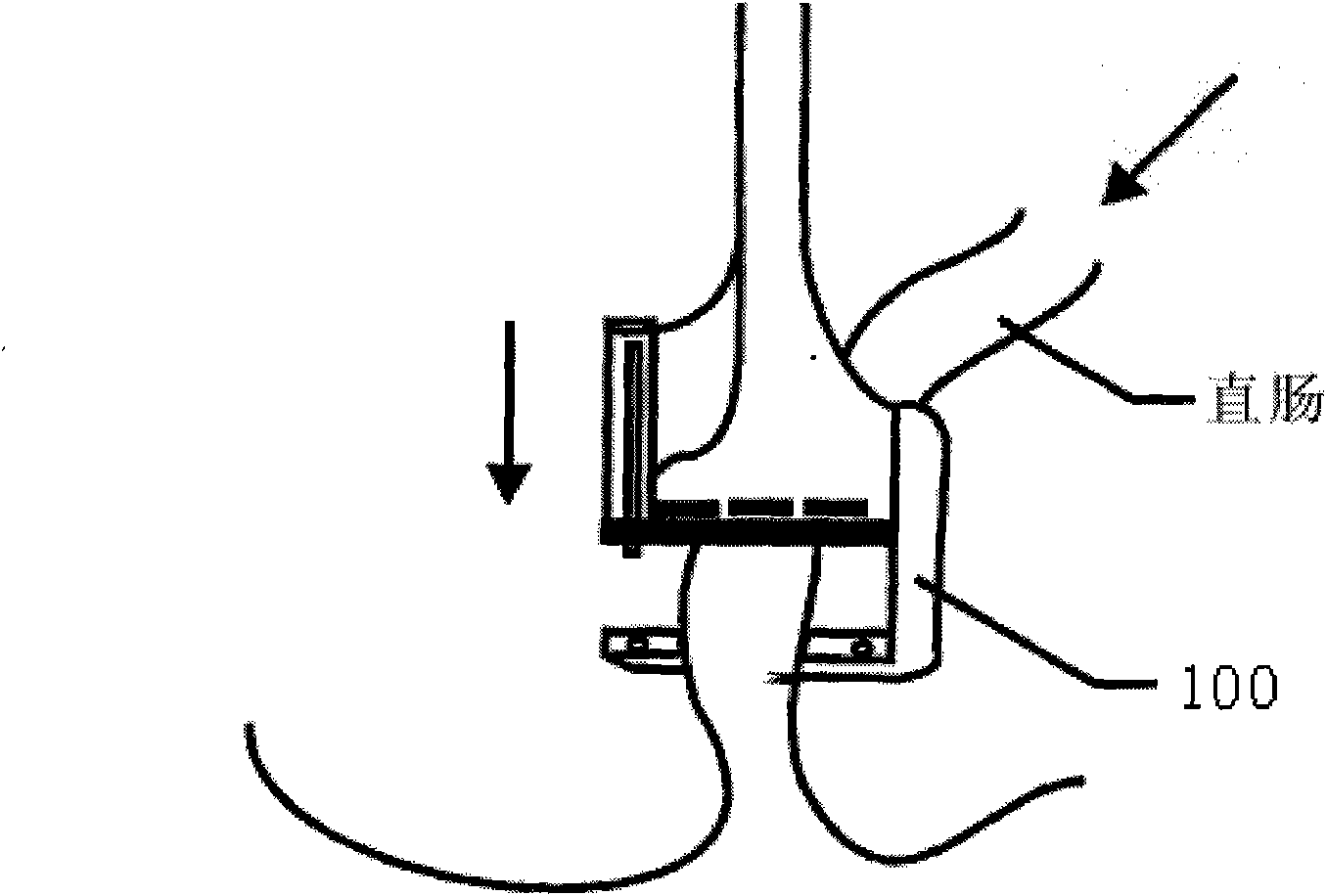

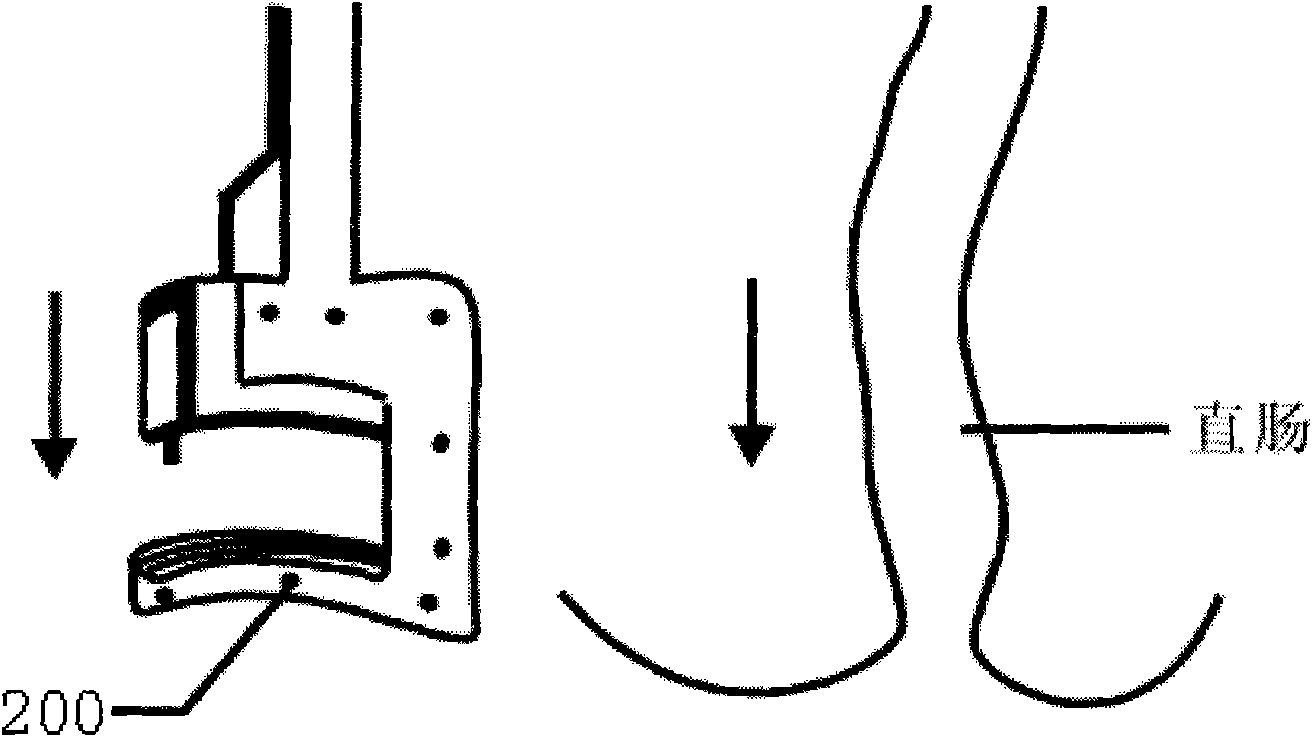

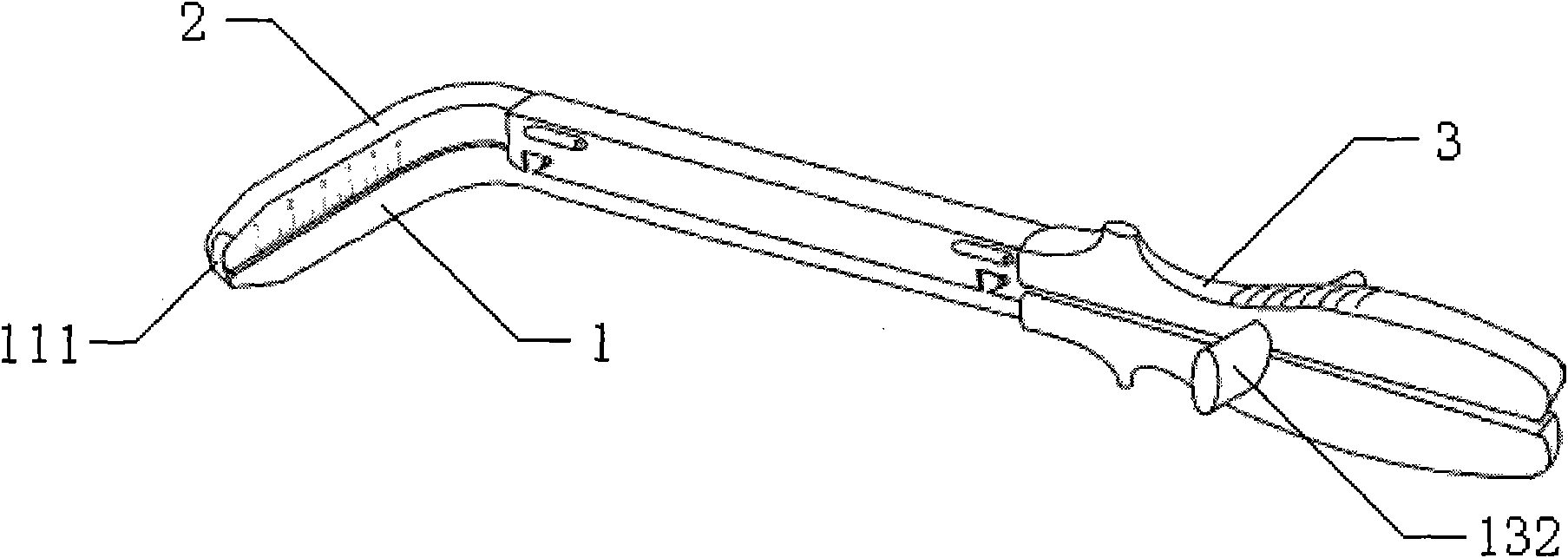

[0027] Attached below Figure 3-Figure 9 , the embodiment of the present invention will be described in detail.

[0028] refer to Figure 3-Figure 5 , the present embodiment mainly includes a staple cartridge assembly 1, an anvil assembly 2 cooperating with the staple cartridge assembly 1 up and down, and a closing handle 3 connected with the staple anvil assembly 2, and the staple cartridge assembly 1 and the staple anvil assembly 2 respectively include a The cutting and suturing ends 11, 21, the intermediate connecting parts 12, 22, and the holding ends 13, 23, wherein:

[0029] The cutting and suturing ends 11, 21 of the staple cartridge assembly 1 and the staple anvil assembly 2 are smoothly deflected by a preset angle relative to the middle connecting portion 12, 22 and the gripping end 13, 23; and

[0030] Please refer to Figure 5 , Figure 6 and Figure 9 , the staple cartridge assembly 1 includes a blade assembly 112 arranged in the slide groove 110 and a staple ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com