Suit sleeve cutting method

A sleeve and suit technology, applied in the field of suit sleeve cutting, can solve the problems of ignoring the structural relationship and complicated operation, and achieve the effect of high precision, simple steps and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

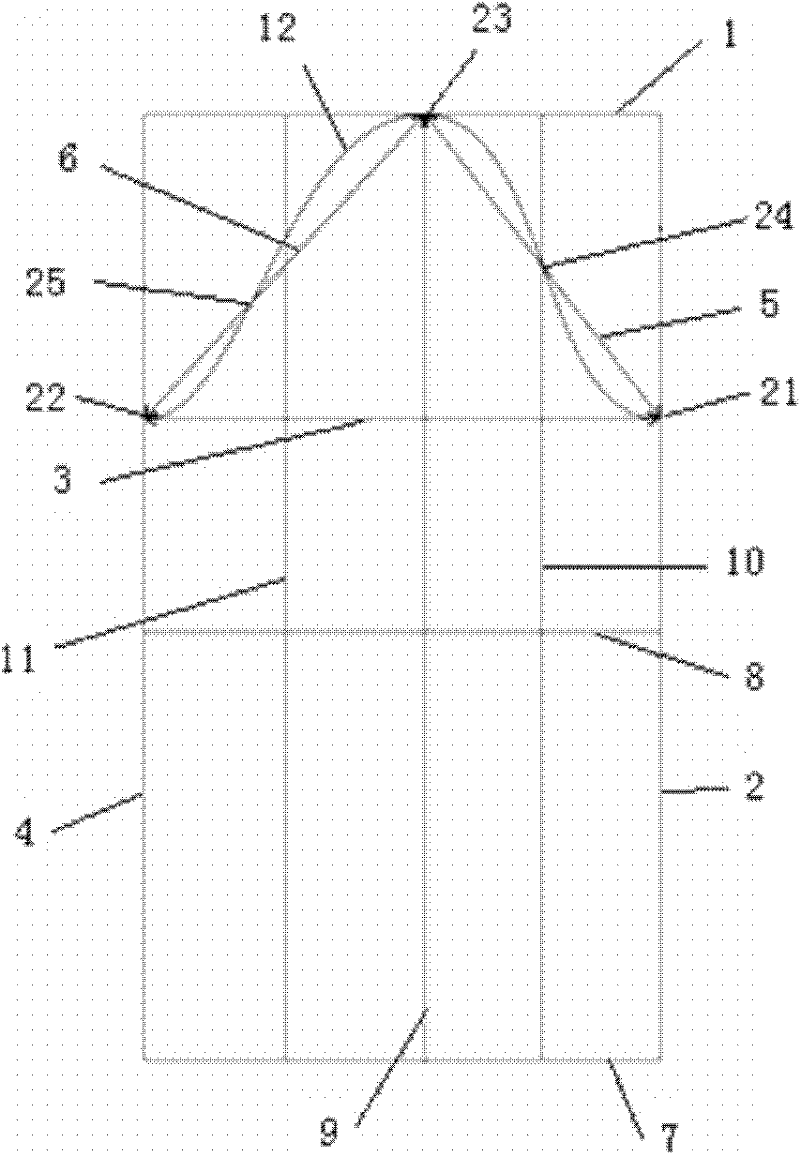

[0022] Embodiment 1: blouse sleeve cutting method, comprises the following steps:

[0023] First, collect the values required for sleeve cutting

[0024] Measure a woman's net bust 82cm, back length 37cm, determine the prototype bust 92cm of the female shirt body, back length 40cm, draw and determine the prototype of the shirt body;

[0025] The measured front armhole length of the shirt body prototype is 21.25cm, and the rear armhole length is 22.25cm;

[0026] The sleeve length measured from the woman's arm is 53cm;

[0027] The upper arm length of the blouse is 1 / 2 of the sleeve length value plus 2.5cm, which is 29cm;

[0028] Second, determine the sleeve fat and sleeve height of the sleeves of the blouse

[0029] Sleeve fat value = 92cm × 1 / 3-2cm = 28.7cm;

[0030] Make a triangle with 28.7cm as the base, 21.25cm as one side, and (22.25+1)cm as the other side, and measure the length of the high line of the triangle to be 16.3cm, which is the high value of Xiushan Mou...

Embodiment 2

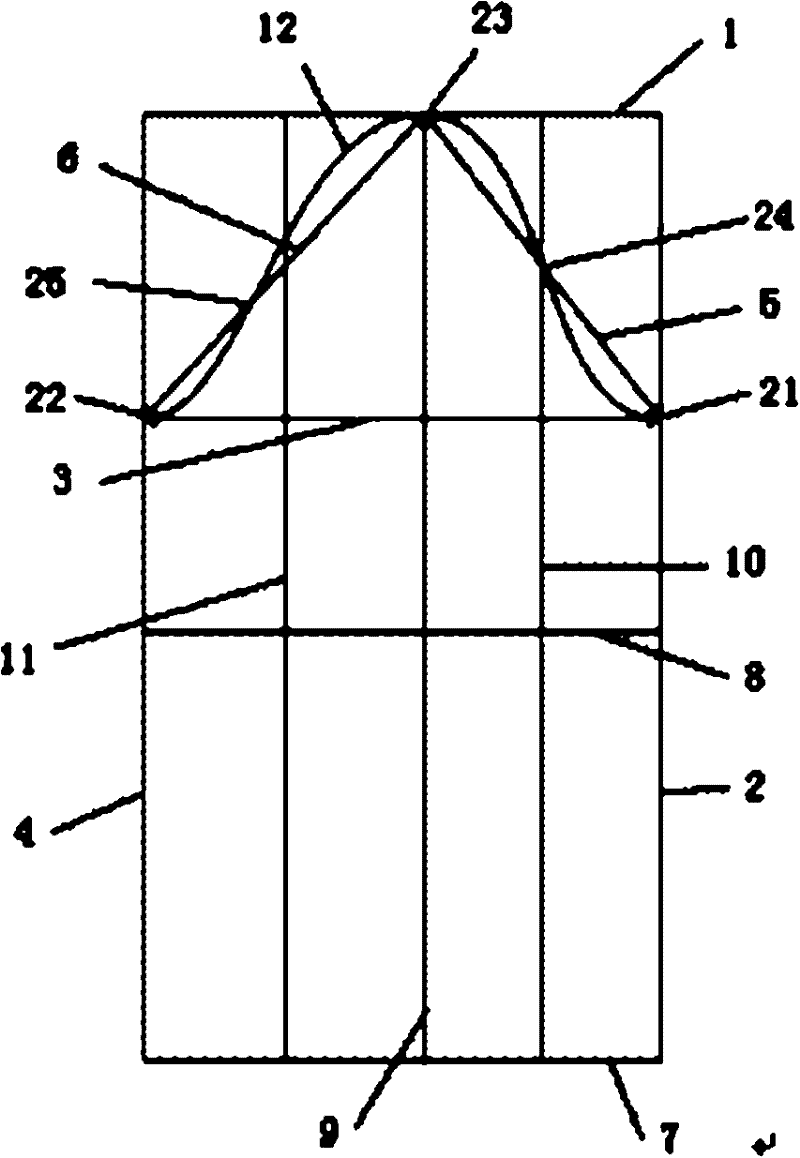

[0034]Embodiment 2: The sleeve cutting of women's business suit comprises the following steps:

[0035] First, collect the values required for sleeve cutting

[0036] Measure a woman's net bust 89cm, back length 40.5cm, determine the bust of the female suit body prototype 99cm, back length 43.5cm, draw and determine the prototype of the female suit body;

[0037] The measured length of the front armhole of the body prototype of the female suit is 23.5cm, and the length of the rear armhole is 24.5cm;

[0038] The sleeve length measured from the woman's arm is 56cm;

[0039] The upper arm length of the female suit is 30.5cm using 1 / 2 of the sleeve length value plus 2.5cm;

[0040] Second, determine the sleeve fat and sleeve height of the sleeves of women's suits

[0041] Sleeve fat value = 99cm × 1 / 3 + 1cm = 34cm;

[0042] Make a triangle with 34cm as the base, 23.5cm as one side, and (24.5+1.5)cm as the other side, and measure the length of the high line of this triangle ...

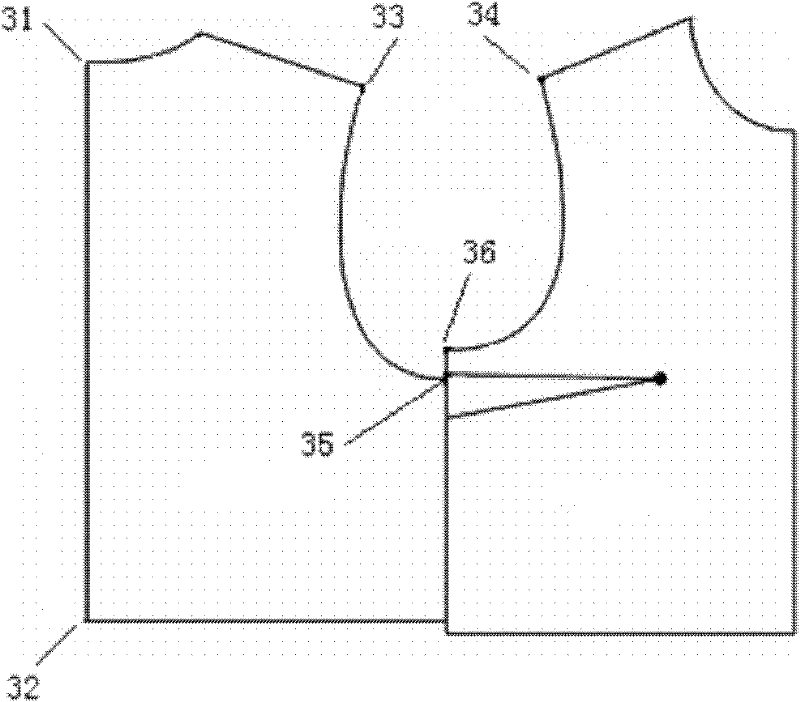

Embodiment 3

[0046] Embodiment 3: Men's suit sleeve cutting, comprises the following steps:

[0047] First, collect the values needed for sleeve cutting

[0048] Measure a man's bust of 108cm and back length of 42.5cm, determine that the bust of the male suit body prototype is 118cm, and his back length of 45.5cm, and draw the prototype of the suit body;

[0049] The measured length of the front armhole of the suit body prototype is 24.5cm, and the length of the rear armhole is 26.5cm;

[0050] The sleeve length measured from the male arm is 62.5cm;

[0051] The upper arm length is 1 / 2 of the sleeve length plus 2.5cm, which is 33.75cm.

[0052] Second, determine the sleeve fat value and sleeve height value of men's suit sleeves

[0053] Sleeve fat value = 118cm × 1 / 3 + 5cm = 44.3cm

[0054] Take 44.3cm as the base, 24.5cm as one side, and (26.5+1)cm as the other side to form a triangle, and measure the length of the high line of this triangle to be 13.6cm, which is the high value o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com