Lead-acid battery composite negative plate

A lead-acid battery and negative plate technology, applied in the field of electrochemical power supply, can solve the problems of electrolyte loss, hydrogen evolution, failure of composite plate lead-acid battery, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] (1) Paste and make negative plate according to conventional lead paste formula;

[0023] (2) coating the capacitor layer coating on both sides of the negative plate respectively, the coating amount is 1% of the weight of the negative active material to form a composite negative plate, and the capacitor layer slurry formula is as follows in parts by weight: coated with lead Compound activated carbon: 50g, the loading of lead compound coated on activated carbon is 0.5% of the mass of activated carbon, the specific surface area of activated carbon is 1000m 2 / g, groove black: 20g, styrene-butadiene rubber: 5g, deionized water: 200g;

[0024] Wherein be coated with the preparation method of the gac of lead compound as follows:

[0025] (1), 10g of activated carbon to be treated is added to Pb(AC) with a concentration of 0.5g / L 2 In 0.1L of solution;

[0026] (2), above-mentioned active carbon lead acetate mixed solution is heated in electric heater earlier, causes the ...

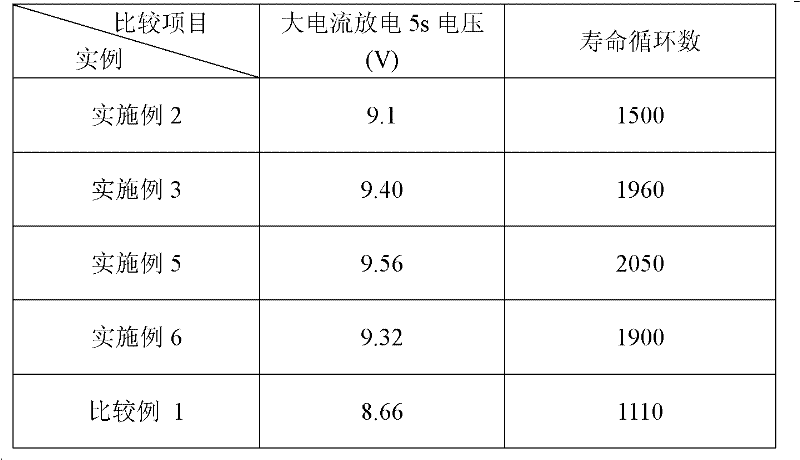

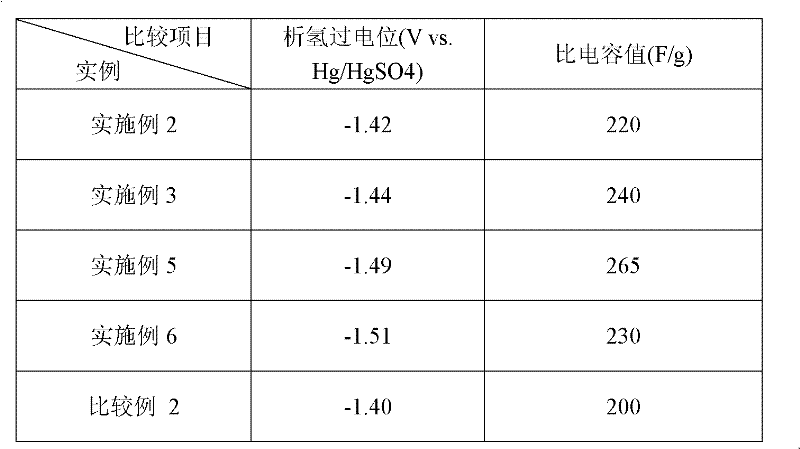

Embodiment 2

[0031] (1) Paste and make negative plate according to conventional lead paste formula;

[0032] (2) coating the capacitor layer coating on both sides of the negative plate respectively, the coating amount is 2% of the weight of the negative active material to form a composite negative plate, and the capacitor layer slurry formula is as follows in parts by weight: coated with lead Compound activated carbon: 55g, the loading of lead compound coated on activated carbon is 5% of the mass of activated carbon, the specific surface area of activated carbon is 2000m 2 / g, acetylene black: 25g, neoprene: 10g, deionized water: 250g;

[0033] Activated carbon coated with lead compounds is prepared as follows:

[0034] (1), 10g of activated carbon to be treated is added to Pb(AC) with a concentration of 5g / L 2 In 0.1L of solution;

[0035] (2), above-mentioned active carbon lead acetate mixed solution is heated in electric heater earlier, causes the moisture in the mixed solution to ...

Embodiment 3

[0040] (1) Paste and make negative plate according to conventional lead paste formula;

[0041] (2) coating the capacitor layer coating on both sides of the negative plate respectively, the coating amount is 2% of the weight of the negative active material to form a composite negative plate, and the capacitor layer slurry formula is as follows in parts by weight: coated with lead Compound activated carbon: 55g, the loading of lead compound coated on activated carbon is 10% of the mass of activated carbon, the specific surface area of activated carbon is 2000m 2 / g, acetylene black: 25g, neoprene: 10g, deionized water: 250g;

[0042] Activated carbon coated with lead compounds is prepared as follows:

[0043] (1), 10g of active carbon to be treated is added to Pb(AC) with a concentration of 10g / L 2 In 0.1L of solution;

[0044] (2), above-mentioned active carbon lead acetate mixed solution is heated in electric heater earlier, causes the moisture in the mixed solution to e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com