A method for detecting internal faults of c-c4f8 mixed gas insulated electrical equipment

A technology for electrical equipment and mixed gas is applied in the field of internal faults of c-C4F8 mixed mixed gas equipment, which can solve problems such as failure to detect electrical equipment failures, and achieve the effects of eliminating hidden dangers, simple detection methods and low detection costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

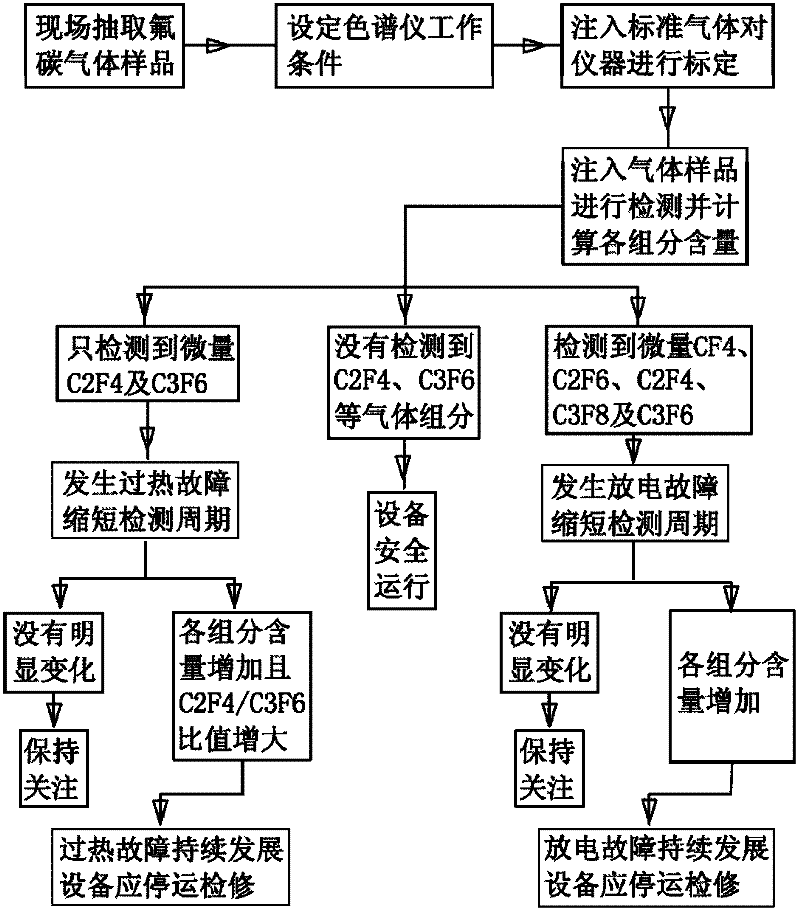

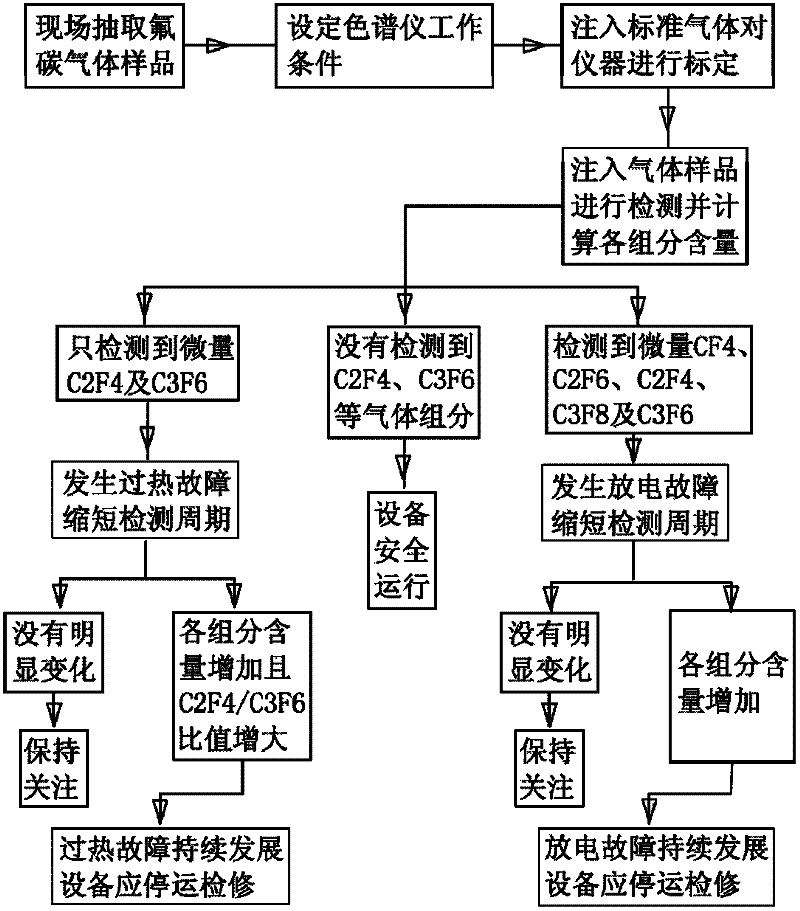

[0019] figure 1 It is a schematic diagram of the analysis process for detecting equipment faults by gas chromatography-mass spectrometry in the present invention. Such as figure 1 As shown, the present invention is a method for detecting internal faults of c-C4F8 mixed gas insulated electrical equipment by gas products in a kind of equipment, which comprises the following steps:

[0020] Step 1: Use a sampling bottle to extract a 200mL gas sample from the electrical equipment for use;

[0021] Step 2: Select a capillary column with a length of 60 m and an inner diameter of 0.32 mm as the chromatographic column. The chromatographic carrier gas is helium with a purity greater than or equal to 99.99%. The carrier gas flow rate is 1 mL / min. The injection split ratio was 20:1. When the gas detector adopts a thermal conductivity detector, the det...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com