Straight wing hydroelectric power generation device

A technology of hydroelectric power generation and straight wings, which is applied in the directions of hydropower generation, renewable energy power generation, engine components, etc., can solve the problems of unsuitability of water turbines, and achieve good application value, high hydraulic conversion efficiency, and improved efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

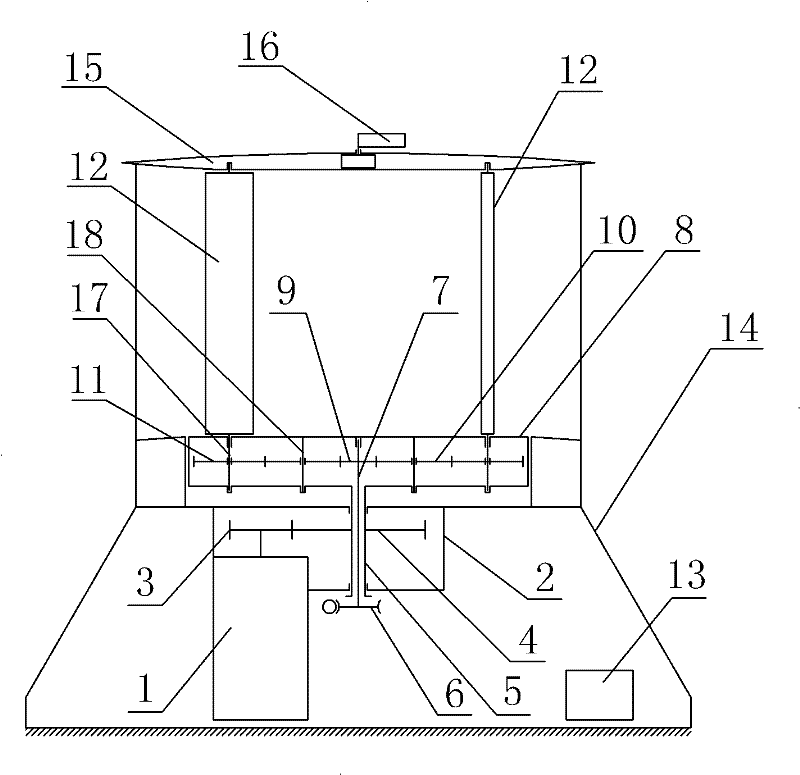

[0025] Embodiment one: if Figure 1-3 As shown, the straight-wing hydroelectric power generation device of this embodiment includes a generator 1, a gearbox 2, a generator gear 3, a main gear 4, a main shaft 5, a water flow orientation controller 6, a transmission shaft 7, a rotating disc 8, and a central gear 9 , bridge gear 10, paddle gear 11, paddle 12, base 14, guide plate 15, water flow sensor 16, paddle shaft 17, the longitudinal section of base 14 is isosceles trapezoidal shape, and it forms accommodation area , a generator 1 and a gear box 2 are built into the accommodation area, the shaft of the generator 1 extends into the gear box 2, and is fixedly connected with the middle part of the gear 3 in the gear box 2, the gear 3 meshes with the main gear 4, and the main gear 4 is also in the gearbox 2. The middle part of the main gear 4 passes through the main shaft 5, and the two are fixedly connected. The lower end of the main gear 5 and the lower wall of the gear box 2...

Embodiment 2

[0031] Embodiment two: see Figure 4 , using a direct-drive generator 1, the generator seat 2 is fixed on the upper bottom of the base 14, and its shaft is directly connected to the main shaft 5 and directly driven by the main shaft 5, thereby saving the transmission mechanism and further simplifying the structure of the generator. For other content of this embodiment, refer to Embodiment 1.

Embodiment 3

[0032] Embodiment three: see Figure 5 , The transmission part of this embodiment adopts a toothed belt or a chain 19, and the central gear 9 is connected with the paddle gear 11 through a toothed belt or a chain 19. For other content of this embodiment, refer to Embodiment 1 or Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com