Container lock products and their heat treatment process and equipment

A technology for heat treatment equipment and containers, which is applied in heat treatment equipment, heat treatment furnaces, manufacturing tools, etc., and can solve problems such as increased amount of curved crystal martensite, high material cost, poor plasticity and toughness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

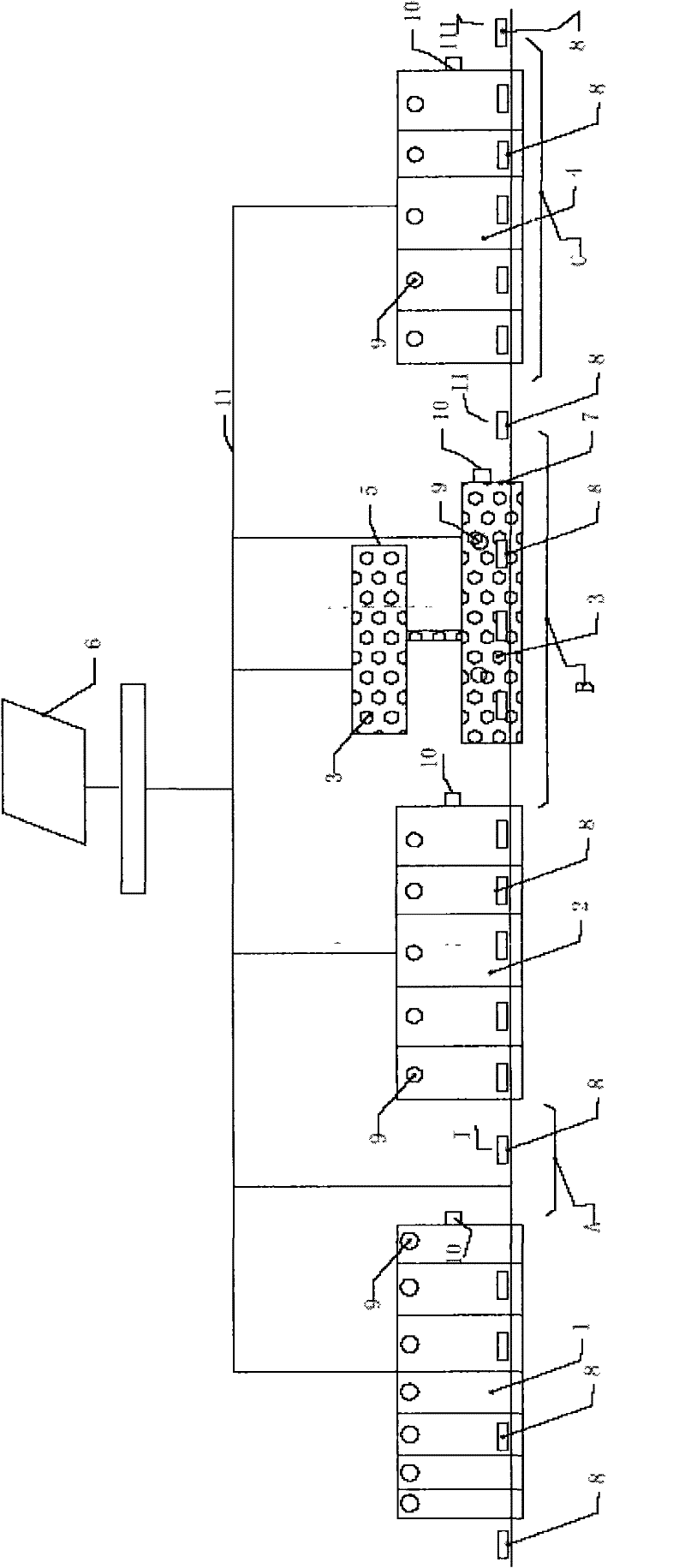

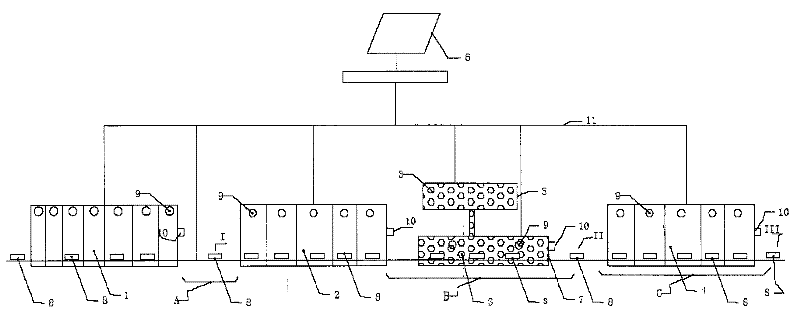

Image

Examples

Embodiment Construction

[0016] In order to solve the above technical problems, the present invention provides a heat treatment process and equipment compatible with a new type of container lock product. The material is 25CrMnSi. The material avoids the use of relatively expensive alloy metal elements in the prior art, and reduces the metal cost. At the same time, 25CrMnSi of this technology is used as low-carbon steel (carbon content less than or equal to 0.30%), and the structure of low-alloy steel after quenching is mainly martensite, which can ensure that it has the strength and hardness of the prior art and has high plasticity. ,toughness. However, the carbon content of 42CrMo in the prior art is greater than 0.30%. After quenching, the amount of bent grain martensite begins to increase, and the plasticity and toughness are poor under the same strength and hardness conditions. Therefore, the use of 25CrMnSi material of this technology not only guarantees the requirements of mechanical properties...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com