Semi-automatic tin dipping machine

A tin dipping machine and semi-automatic technology, applied in tin feeding devices, metal processing equipment, manufacturing tools, etc., can solve the problems of unstable finished product size, difficult to guarantee the appearance quality, inconsistent tin dipping length of braided bell mouth, etc., and achieve the improvement effect , fast speed and good size consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

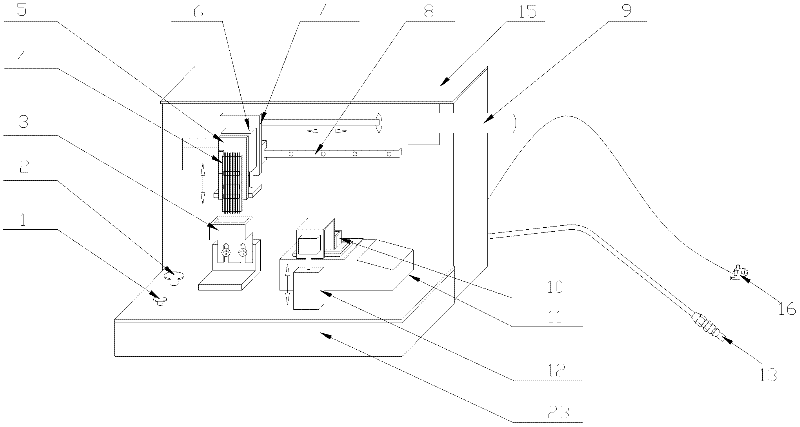

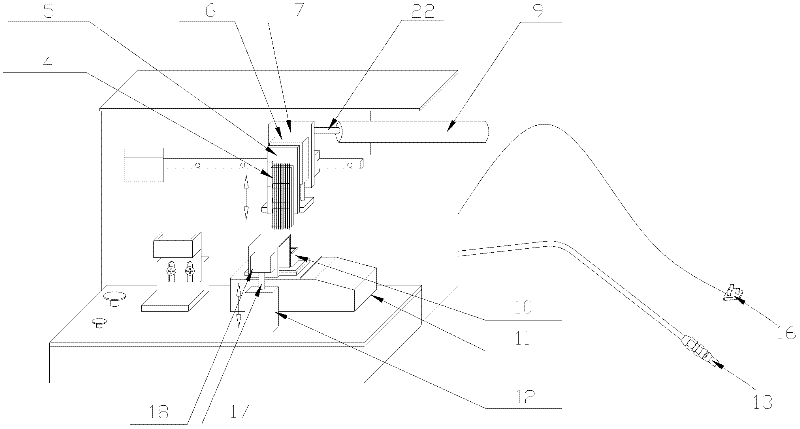

[0024] The present invention will be further described below in conjunction with the accompanying drawings.

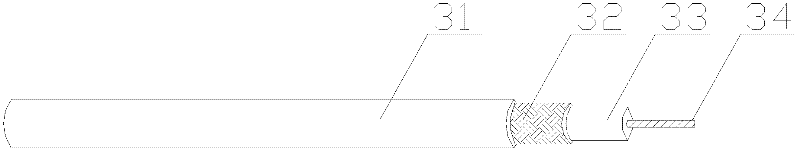

[0025] Such as Figure 2-3 As shown, a semi-automatic tin dipping machine includes start switch 1, emergency stop switch 2, flux tank 2, wiring board 4, positioning plate 5, cylinder two 6, cylinder fixing block 7, guide rail 8, cylinder three 9, dipping Tin bath 10, tin melting furnace 11, cylinder one 12, compressed air connector 13, electrical cabinet 15 and workbench 23. A tin melting furnace 11 is arranged on the workbench 23, and an electrical cabinet 15 is arranged at the rear of the workbench 23, and the electrical cabinet 15 is connected with the power plug 16 through electric wires. A compressed air connector 13 is arranged on the outside of the workbench 23. One end of the compressed air connector 13 is connected to the electrical cabinet 15, and the other end is connected to the air compressor. The electrical cabinet 15 is respectively connected to cylinde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com