Light-emitting diode (LED) lamp controller based on digital pulse-width modulation (PWM) control technology

A technology of LED lamp and control technology, which is applied in the direction of electric lamp circuit layout, light source, lighting device, etc., to achieve the effect of low cost, high current precision and stable light signal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings.

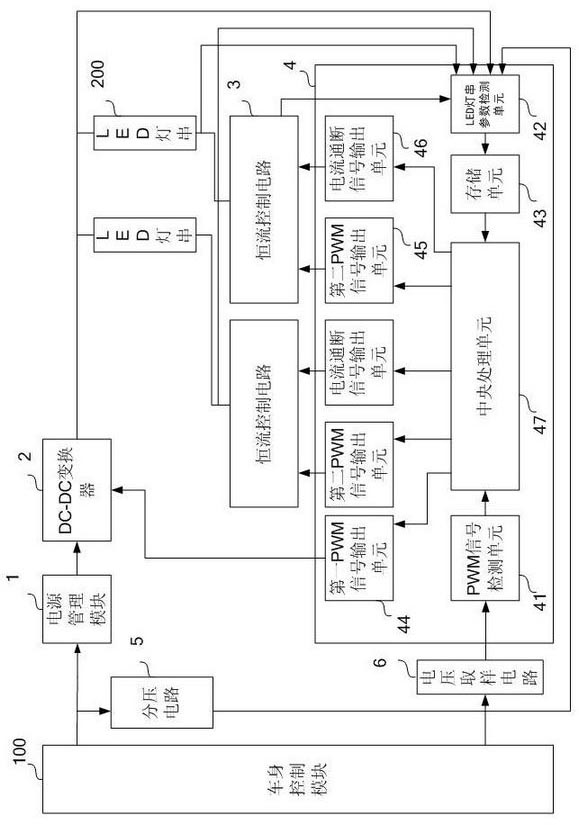

[0023] Such as figure 1 As shown, the LED light controller of the present invention includes a power management module 1, a DC-DC converter 2, and one or more sets of constant current control circuits 3 corresponding to one set of LED light strings or multiple sets of LED light strings and control module 4. The input terminal of the power management module 1 receives the power supply voltage signal input from the outside, the output terminal is electrically connected to the input terminal of the DC-DC converter 2, and the output terminal of the DC-DC converter 2 is connected to a group of LED light strings or multiple groups of LED lights One end of the light string 200 is electrically connected. The DC-DC converter 2 is used to convert the input voltage into the working voltage required by the LED light string.

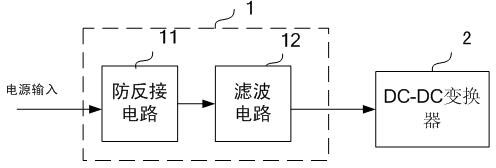

[0024] The structure of the power management module...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com