Crimp-type coaxial connector and connection method thereof

A coaxial cable and connector technology, applied in the direction of connection, conductive connection, connection, etc. through deformation, can solve the problems of cable disconnection, poor tensile strength, easy to be torn off, etc., to avoid special customized pressure Connecting tools, good tensile capacity, and high crimping strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

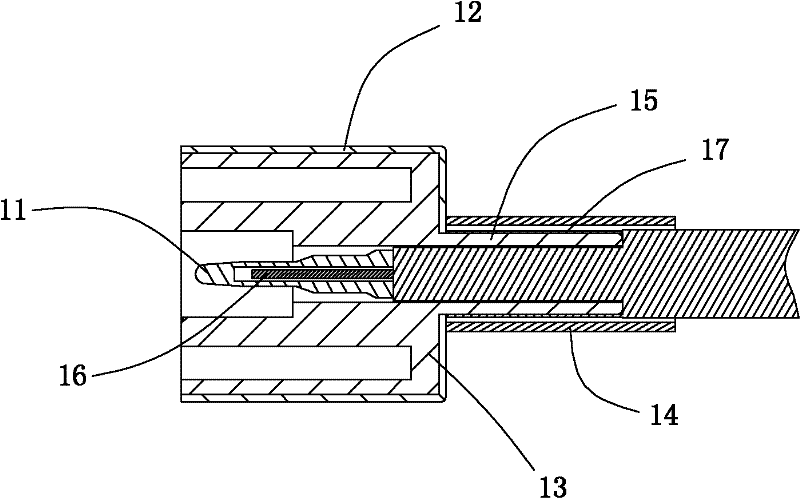

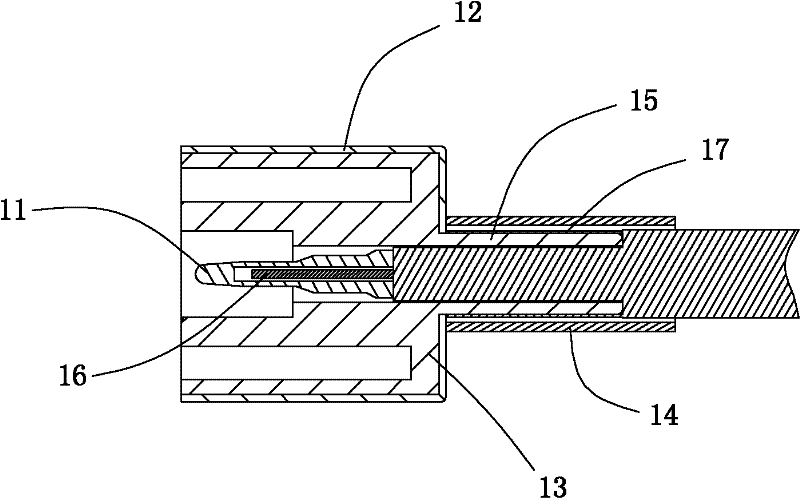

[0023] Such as figure 1 Shown is a structural diagram of a coaxial cable connector in the prior art.

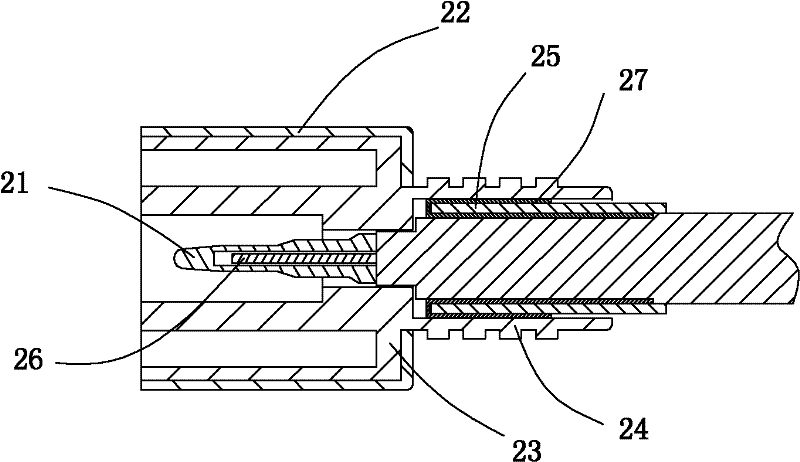

[0024] Such as figure 2 Shown is a structural diagram of a specific embodiment of the present invention, a crimping type coaxial electrical connector, including a crimping pin 21, a shielding shell 22, an insulator 23, and a crimping sleeve 25, the crimping pin is located in the insulator, and the insulator A crimping tube 24 extends out of the shielding shell, the inner diameter of the crimping tube is larger than the outer diameter of the crimping sleeve, and the difference between the inner diameter of the crimping tube and the outer diameter of the crimping sleeve can be selected within the range of 0.5 mm to 2 mm. It is advisable to make the crimping sleeves of uniformly distributed shielding net 27 just able to enter the crimping tube, and the gap between the crimping tube and the shielding net can also be increased or decreased as required, thereby increasing or redu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com