Full-automatic grinding testing instrument

A tester and automatic technology, applied in the field of automatic grinding tester, can solve the problems of human factors, uncertainty of test results, etc., and achieve the effect of convenient and accurate use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

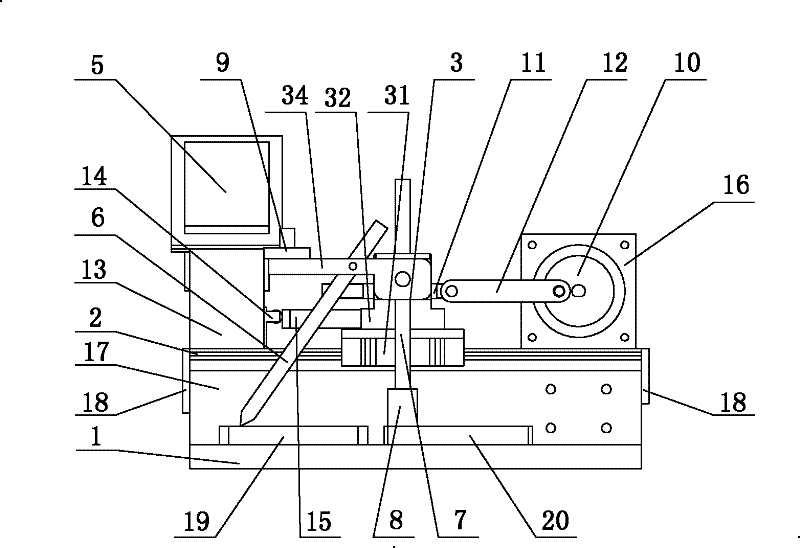

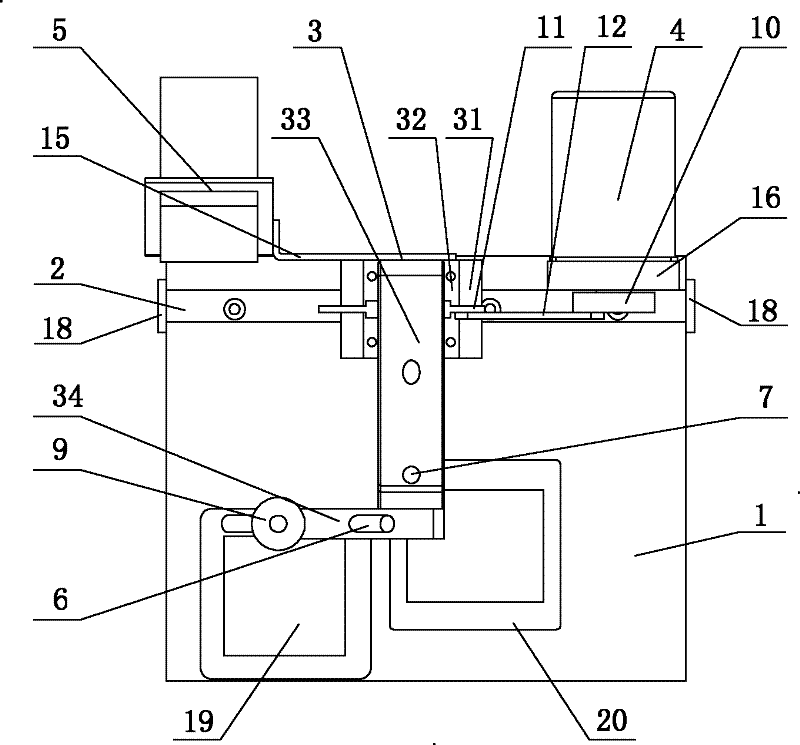

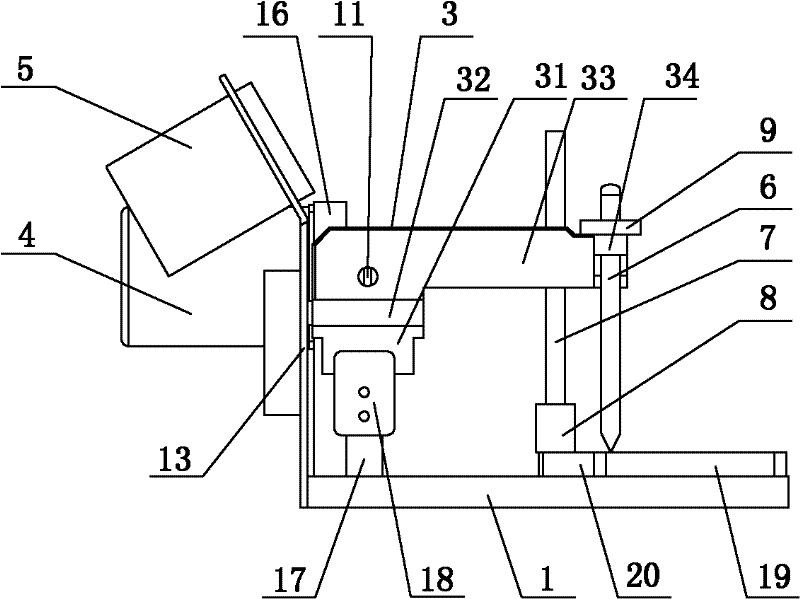

[0017] Such as figure 1 , figure 2 and image 3 As shown, the fully automatic grinding tester includes a workbench 1, a guide rail 2 arranged on the workbench 1, a sliding device 3 arranged on the guide rail 2, a drive motor 4 connected to the slide device 3 on the workbench 1, A digital display 5 corresponding to the sliding device 3 is provided on the workbench 1 , and the first test rod 6 is arranged on the sliding device 3 . Described sliding device 3 comprises the slide block 31 that is located on guide rail 2, is located at the support frame 32 on slide block 31, and described support frame 32 is provided with longitudinal frame 33, and described longitudinal frame 33 is screwed with lateral adjustment. frame 34, and the first test rod 6 is arranged on the horizontal adjustment frame 34. The second test rod 7 corresponding to the first test rod 6 is arranged on the longitudinal frame 33 , and the bottom end of the second test rod 7 is provided with a cotton ball 8 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com