Optimization design method of impeller for cavitation-erosion-resistant centrifugal fan

A centrifugal pump impeller, optimized design technology, applied in the direction of pumps, pump components, mechanical equipment, etc., can solve the problems of backward optimization design methods, low efficiency, poor cavitation performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0084] The method of the present invention is used to optimize the design of a centrifugal pump impeller with an original impeller diameter of 720mm, blade number of 9, rotational speed of 960r / min, and flow design of 440L / s.

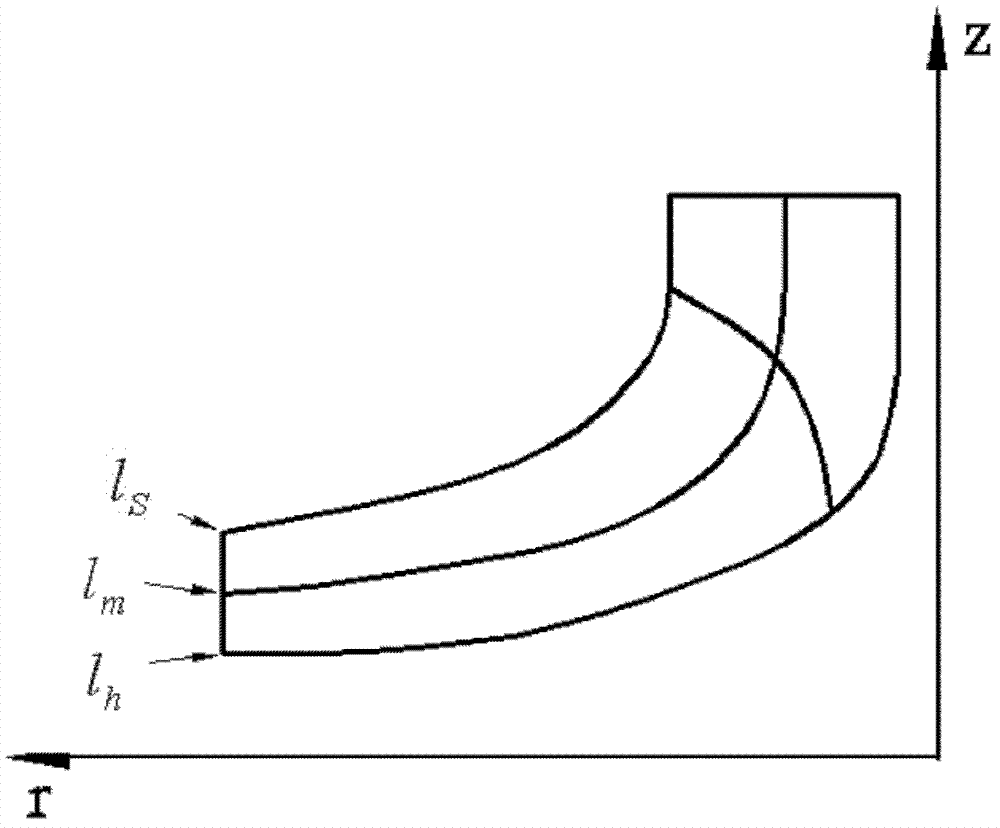

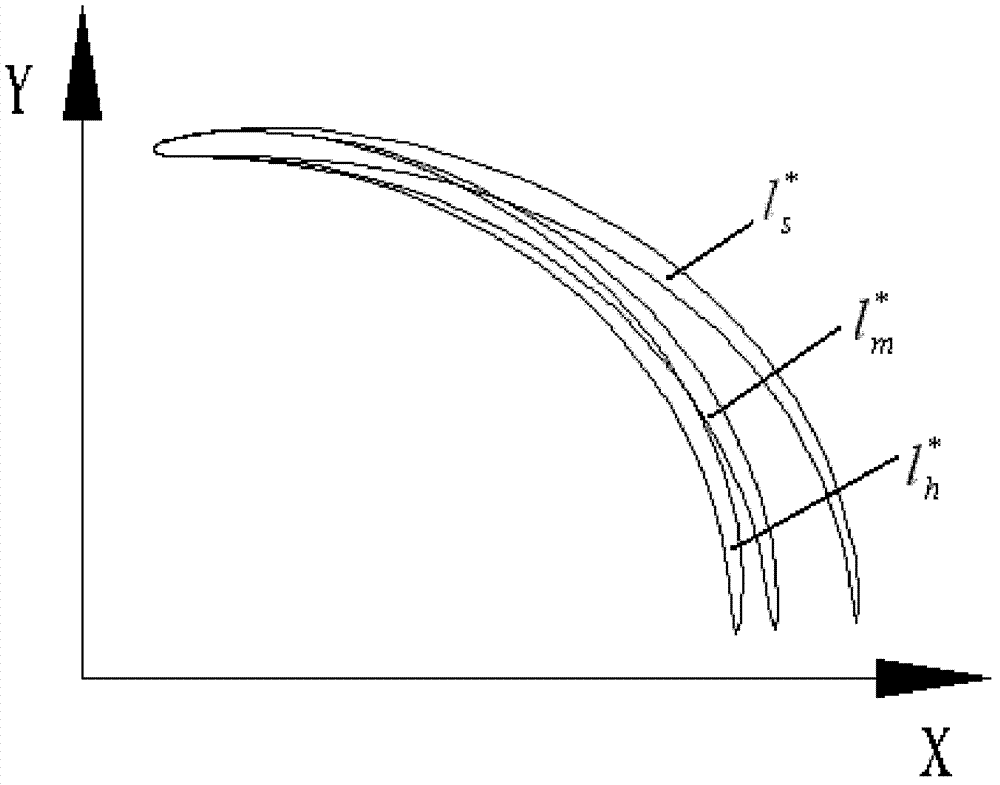

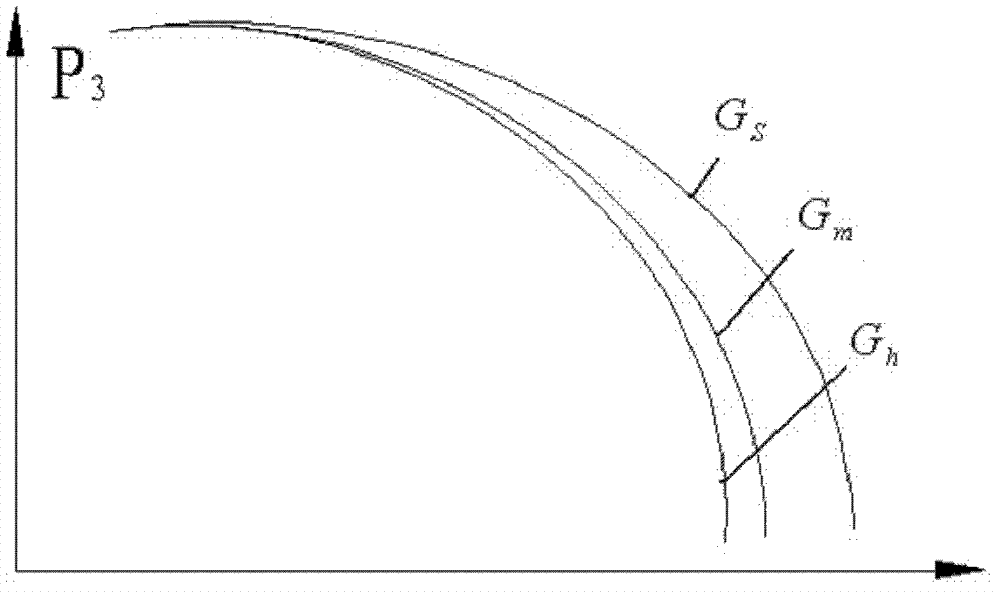

[0085] Step 1. Obtain the two-dimensional airfoil bone line G of the front cover on the circumferential XY plane of the original impeller s , the middle two-dimensional airfoil bone line G m And the two-dimensional airfoil bone line G of the rear cover h . Among them, such as figure 1 As shown, the streamline l of the front cover is obtained from the axial plane projection of the original impeller s , middle streamline l m and the streamline of the rear cover l h . Such as figure 2 Shown is the two-dimensional airfoil profile of the front cover of the original impeller Intermediate 2D airfoil profile And the two-dimensional airfoil profile line of the rear cover Such as image 3 shown, for figure 2 The two-dimensional airfoil bone line ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com