Double-torsion spring mounting bracket and manufacturing method thereof

A technology of torsion springs and mounting brackets, applied in valve devices, engine components, machines/engines, etc., can solve problems such as adverse effects on system reliability, deformation of double torsion springs, and difficulty in ensuring accurate positioning during installation, achieving simple structure, The effect of reducing deformation and precise positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

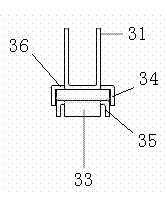

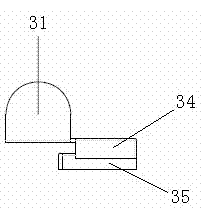

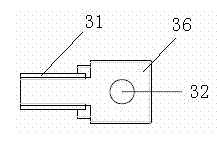

[0022] Such as Figure 1~4 As shown, the double torsion spring mounting bracket of this embodiment includes a plate-shaped main body 36 provided with mounting holes 32. The front part of the main body 36 is provided with two blocking pieces 31 perpendicular to the main body. Both sides of the main body 36 are provided with The vertical first thrust plate 34; the rear part of the main body 36 is connected with an auxiliary plate 37 parallel to the main body and located below the main body. The auxiliary plate 37 has holes corresponding to the positions of the mounting holes 32, and the two sides of the auxiliary plate 37 are all provided below There is a vertical second thrust piece 35, and a vertical front thrust piece 33 is arranged under the front part of the accessory plate 37; the distance between the first thrust pieces 34 on both sides of the main body 36 is greater than that of the second thrust piece on both sides of the accessory plate The first thrust plate 34 extend...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com