Loose bed and bedrock layer mixed water-intaking and well-forming process for geothermal well

A technology of loose layers and bedrock layers, which is applied in the field of geothermal wells in which loose layers and bedrock layers are mixed to draw water into wells, can solve problems such as rising water temperature, achieve the effects of increasing water temperature, increasing maximum efficiency, and ensuring water output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

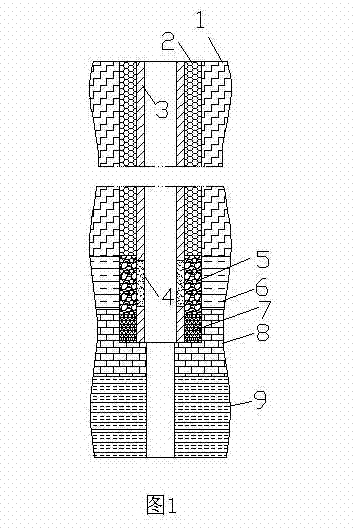

[0011] Geothermal well loose layer and bedrock layer are combined to take water to form a well. The process steps are: ① Drill the well with mud positive circulation drilling technology to a depth of 5-10 meters below the complete bedrock surface; The downhole wall pipe in the non-loose pore water layer section, and the permeable pipe in the loose pore water layer section of the loose layer. ③Annulus filling means injecting cement slurry into the annulus corresponding to the section below the bedrock surface. The filter material is put into the ring hole corresponding to the water layer, and the clay ball is put into the ring hole corresponding to the non-loose pore water layer section of the loose layer. Circulation drilling technology uses a drill bit whose diameter is 5-10mm smaller than the inner diameter of the wellbore pipe to continue drilling in the bedrock layer until the bedrock fissure water layer is reached, and the well can be completed when the water temperature r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com