Arching formwork erecting method for assembled framework beam plate

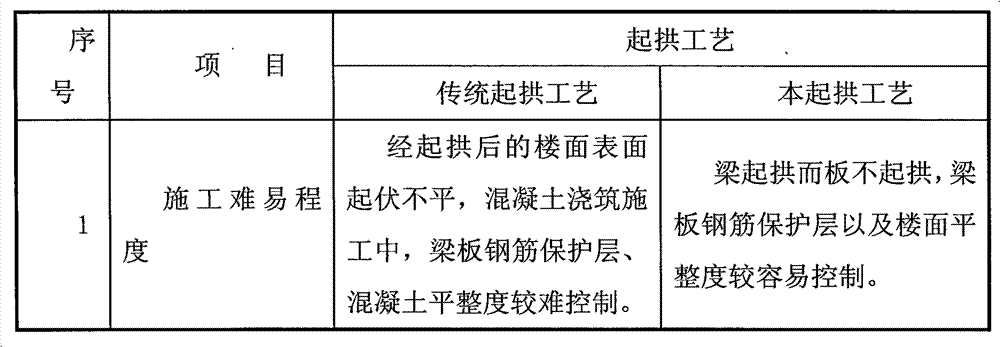

A formwork support method and a frame beam technology, which are applied to the joints of formwork/formwork/work frame, formwork/formwork/work frame, and on-site preparation of building components, which can solve the problem of increased leveling engineering and constant load of beams and slabs increase, increase in the amount of floor leveling works, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] A method for arching and supporting formwork of a prefabricated frame beam slab, comprising the following steps:

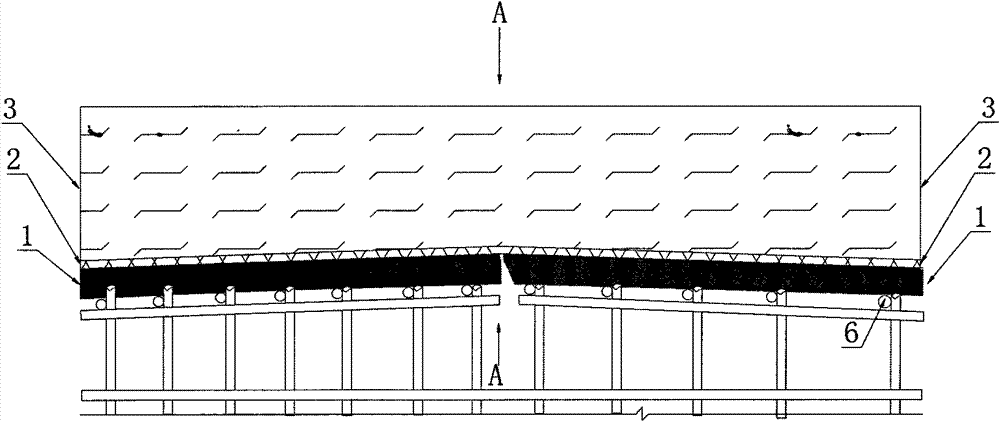

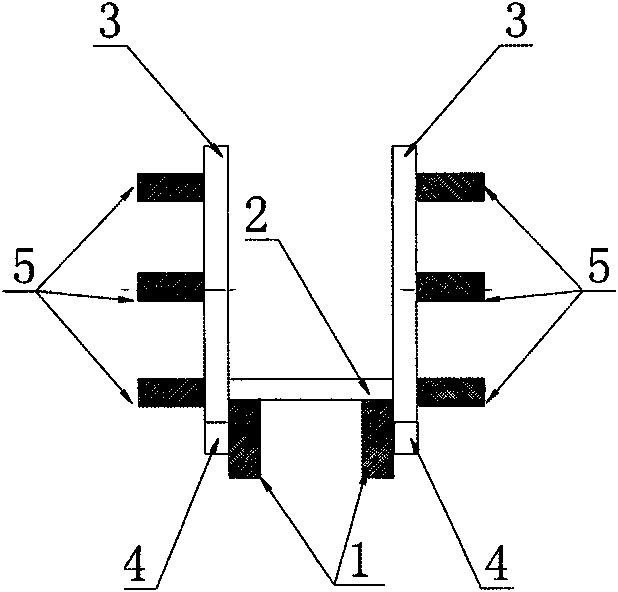

[0033] (1) Foundation engineering: determine the span value between the corresponding beam supports, the construction arch height, the elevation of the beam bottom, the elevation of the top of the beam, and the elevation of the floor, build the beam support frame, and erect a group on the beam support frame, etc. Horizontal connecting rods 6 with parallel spacing, wherein the beam support frame includes a cross bar, a vertical rod and an adjustable base;

[0034] (2) Install a group of beam bottom corrugations 1 on the horizontal connecting rod 6, and fixedly install the beam bottom formwork 2 on the beam bottom corrugation 1. , Beam bottom flute 1 on the lower right side; adjust the height of the beam support frame and each horizontal connecting rod 6 through the adjustable base, until the beam bottom flute 1 and the beam bottom formwork 2 realize the foll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com