Method for producing alcohol from straws and distilled grains abandoned during production of white spirit

A technology for straw and liquor, which is applied in the field of deep processing and fermentation of agricultural and sideline products to prepare alcohol, can solve the problems of low utilization rate, insufficient utilization of waste biomass resources of agricultural and sideline products, etc., and achieves high alcohol yield, high glucose utilization rate, and environmental The effect of pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

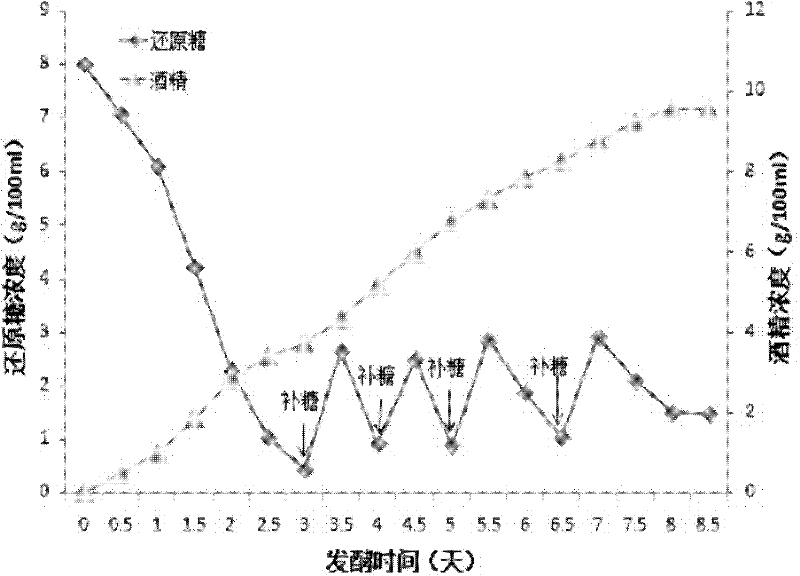

Embodiment 1

[0028] The distilled grains used in this example are the one-time distilled grains provided by Sichuan Shuijingfang Co., Ltd., and the straws are rice stalks collected in the suburbs of Chengdu.

[0029] (1) Straw crushing

[0030] Use a hammer mill to finely pulverize the straw, requiring more than 90% of it to pass through a 10-mesh sieve;

[0031] (2) Concentrated sulfuric acid saccharification and hydrolysis

[0032] Get the fresh distilled grains of liquor and mix with straw by 1: 0.6 mass ratio, mixture and concentration 80wt%H 2 SO 4 Stir and saccharify for 30 minutes according to the mass-to-volume ratio of 1:1, add water until the sulfuric acid concentration in the liquid is 20 wt%, and hydrolyze in a boiling water bath for 100 minutes;

[0033] (3) Neutralization of acid sugar solution

[0034] Filter the above saccharified hydrolyzate, rinse the acid residue twice with hot water at a temperature of 80°C, collect the washing liquid, and combine the washing liquid...

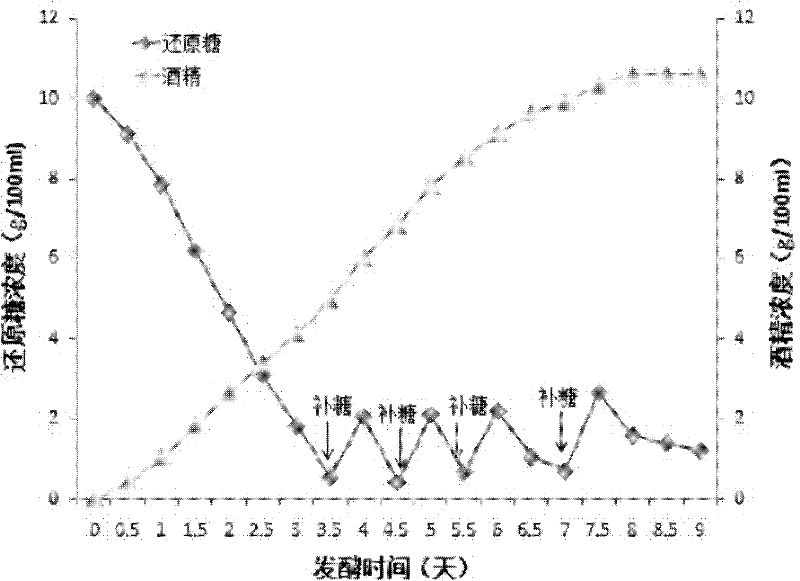

Embodiment 2

[0038] The distilled grains used in this example are the one-time distilled grains provided by Sichuan Shuijingfang Co., Ltd., and the straws are rice stalks collected in the suburbs of Chengdu.

[0039] (1) Straw crushing

[0040] Use a hammer mill to finely pulverize the straw, requiring more than 90% of it to pass through a 10-mesh sieve;

[0041] (2) Concentrated sulfuric acid saccharification and hydrolysis

[0042] Get the fresh distilled grains of liquor and mix with stalk by 1:1 mass ratio, mixture and concentration 80wt%H 2 SO 4 Stir and saccharify for 40 minutes according to the mass-to-volume ratio of 1:1.5, add water until the sulfuric acid concentration in the liquid is 25 wt%, and hydrolyze in a boiling water bath for 120 minutes;

[0043] (3) Neutralization of acid sugar solution

[0044] Filter the above saccharified hydrolyzate, rinse the acid residue twice with hot water at a temperature of 80°C, collect the washing liquid, and combine the washing liquid;...

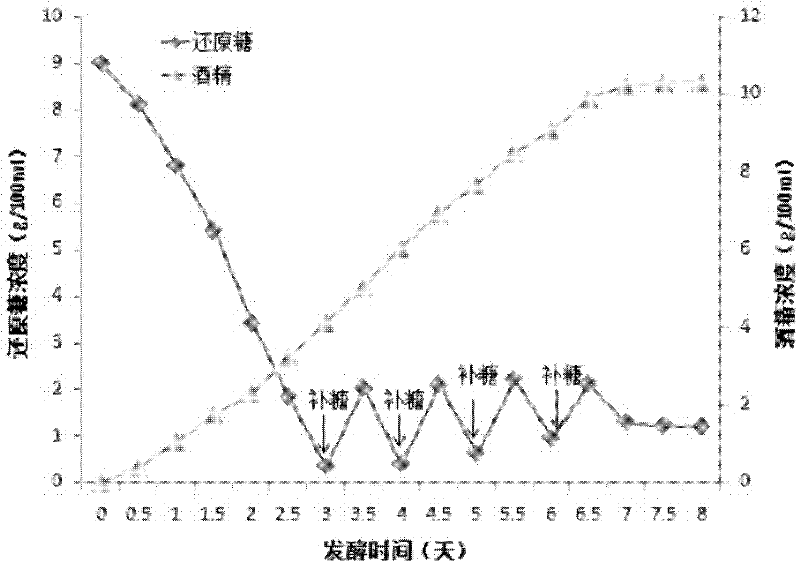

Embodiment 3

[0048]The distilled grains used in this example are the one-time distilled grains provided by Sichuan Shuijingfang Co., Ltd., and the straws are rice stalks collected in the suburbs of Chengdu.

[0049] (1) Straw crushing

[0050] Use a hammer mill to finely pulverize the straw, requiring more than 90% of it to pass through a 10-mesh sieve;

[0051] (2) Concentrated sulfuric acid saccharification and hydrolysis

[0052] Get the fresh distilled grains of liquor and mix with stalk by 1: 0.8 mass ratio, mixture and concentration 80wt%H 2 SO 4 Stir and saccharify for 35 minutes according to the mass-to-volume ratio of 1:1.2, add water until the sulfuric acid concentration in the liquid is 22 wt%, and hydrolyze in a boiling water bath for 110 minutes;

[0053] (3) Neutralization of acid sugar solution

[0054] Filter the above saccharified hydrolyzate, rinse the acid residue twice with hot water at a temperature of 80°C, collect the washing liquid, and combine the washing liqui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com