Multi-adaption pressure-type integral water purifier

A pressure-type water purifier technology, applied in the field of water treatment, can solve the problems of reducing floor space, connecting pipelines, and high cost of construction, achieving small head loss and improving the effect of collision and condensation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below through two equipment examples.

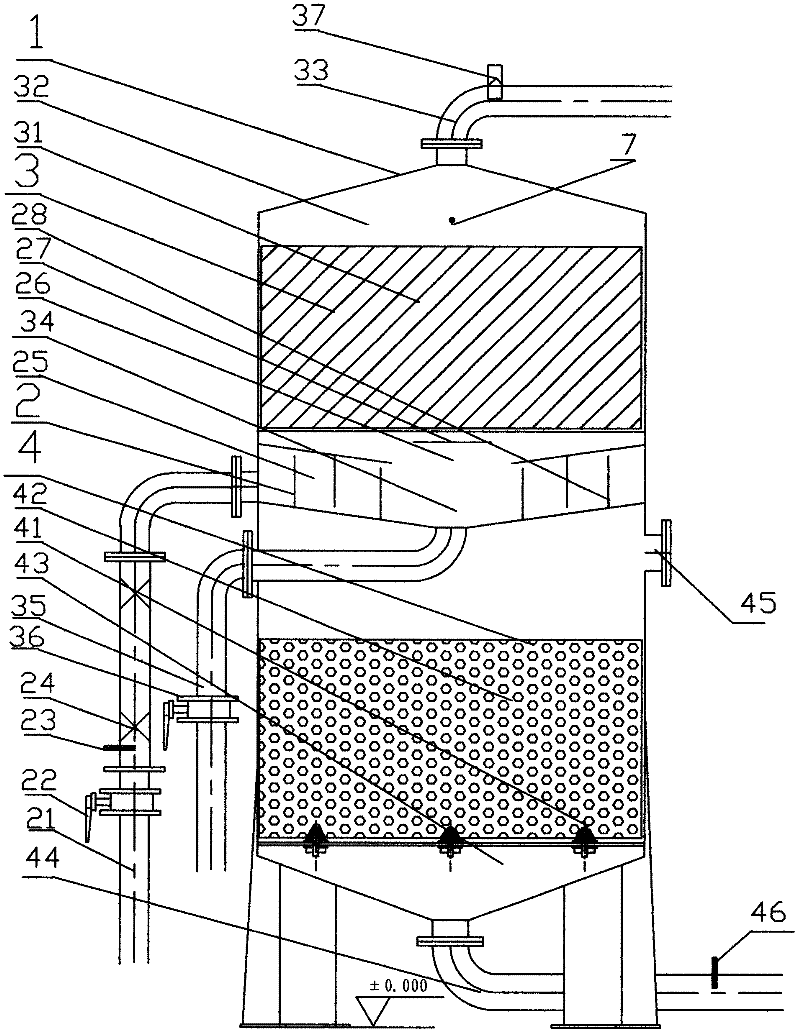

[0026] There is mountain stream water as the source water in a rural area, and a small water plant is planned to be built 8m below the slope of the water source to supply farmers with a daily water supply of 600m 3 , to build a fully hydraulic pressure integrated water purifier with automatic control, such as Figure 4 shown. details as follows:

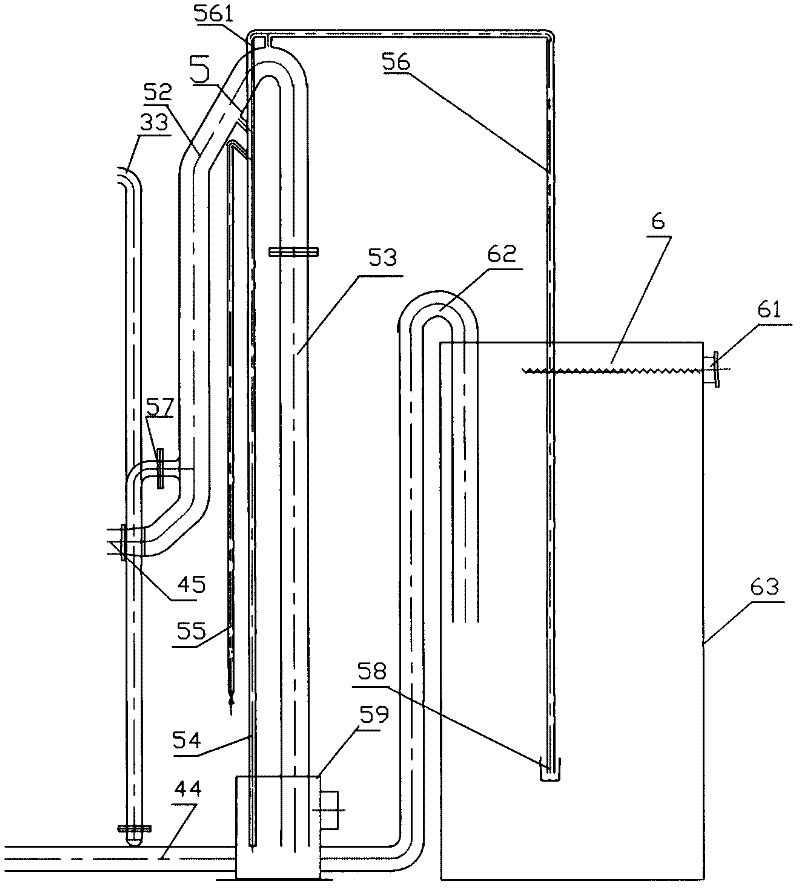

[0027] This equipment adopts a pressure type tank body 1 with a diameter of 2000mm, which is equipped with a connecting pipe 51. Inside the pressure type tank body 1, there are a coagulation reaction system 2, an inclined tube sedimentation area 3, and a sand filter area 4. Above the coagulation reaction system 2 is an inclined tube sedimentation area. Area 3 and below is the sand filter area 4, the coagulation reaction system 2 is connected with the inclined tube sedimentation area 3 through the buffer zone 2 of the water to be precipita...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com