Bar extruding machine

A technology of extruder and chassis, applied in the field of extrusion molding equipment, can solve the problems of small processing volume, unstable extrusion volume, unsuitable for powder extrusion molding, etc., to improve product quality, increase service life, increase The effect of delivery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

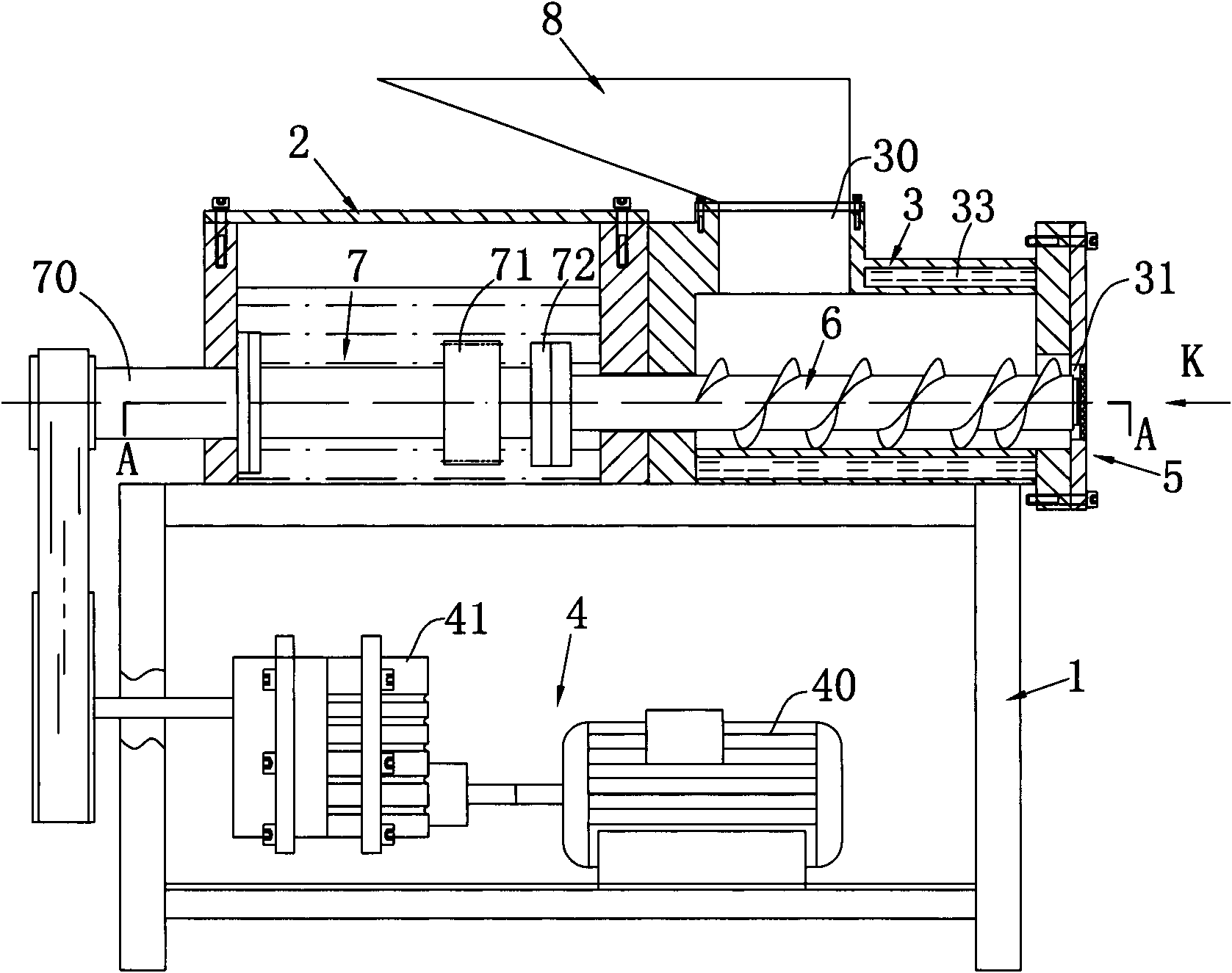

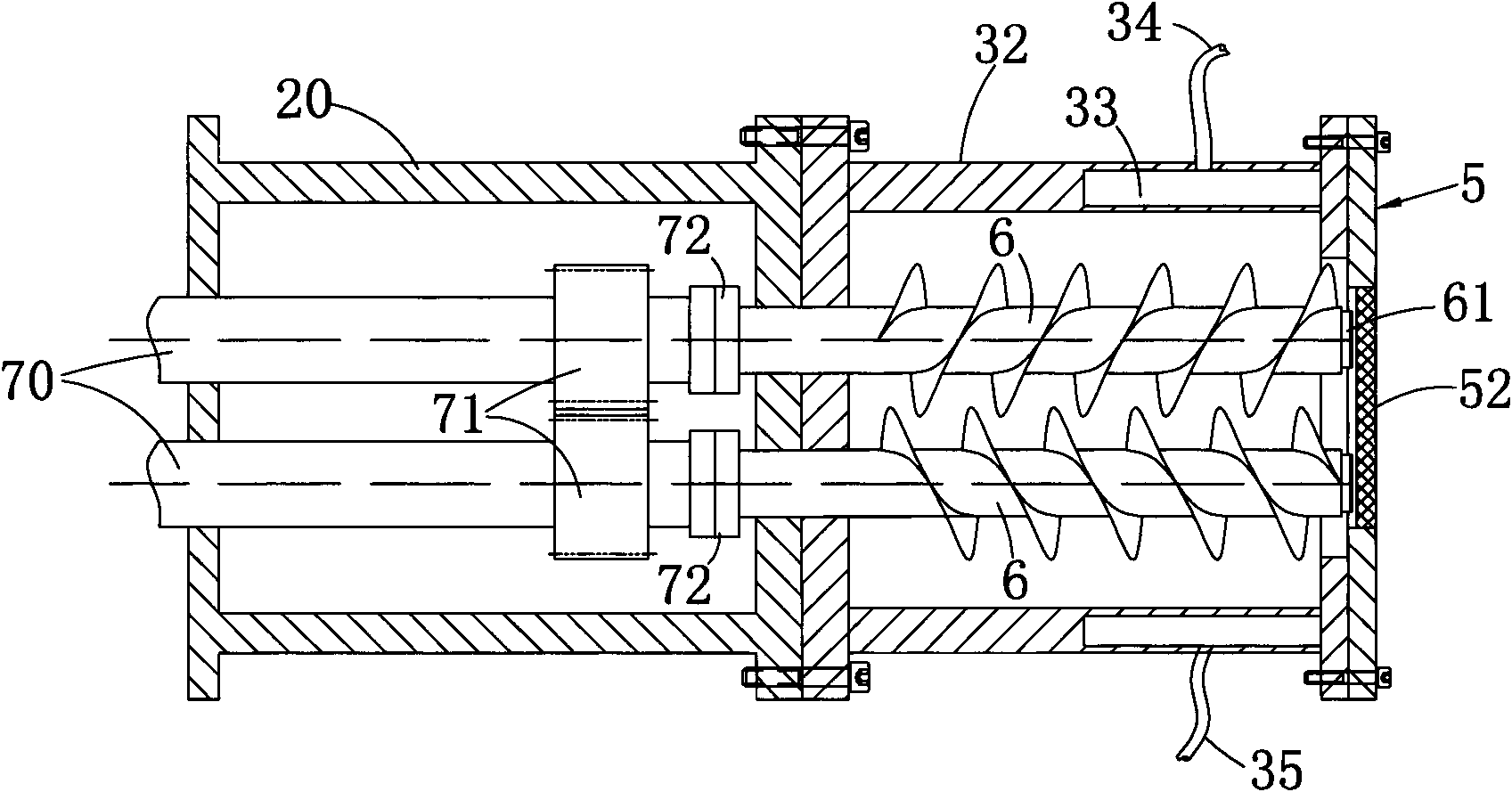

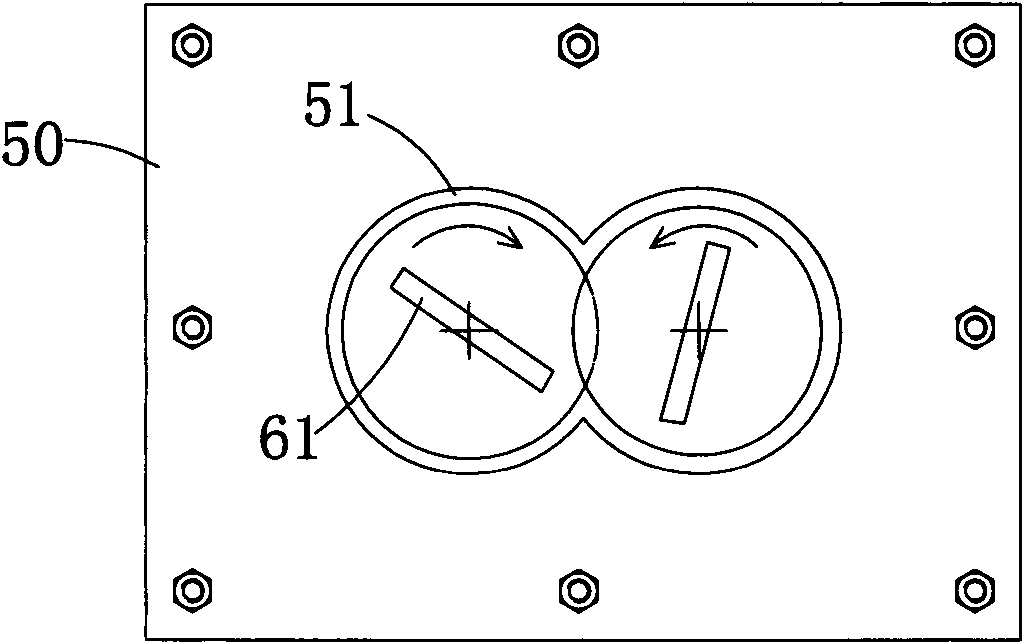

[0017] refer to Figure 1-3 , the present invention provides a kind of extruding machine, comprises frame 1, driving device 4, extruding mechanism, and described extruding mechanism comprises cabinet, is provided with feed port 30 and discharge port 31 on the cabinet, and described discharge A molding die 5 is connected to the mouth 31; a transmission structure 7 and a pair of intermeshing extrusion screws 6 are arranged in the cabinet; the driving device 4 drives the pair of extrusion screws 6 to rotate in different directions synchronously through the transmission structure 7 .

[0018] The chassis includes a transmission box 2 that accommodates the transmission structure 7, and an extrusion box 3 that accommodates the extrusion screw 6 and is sealed with the transmission box 2; the transmission box 2 is filled with lubricating oil; the feed port 30 is located at the extrusion The top of the box 3, the discharge port 31 is located at the front end of the extruding box 3; the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com